Lubrication test method for main speed reducer of drive axle

A technology of main reducer and test method, applied in gear lubrication/cooling, testing of machine/structural components, instruments, etc., can solve the problems of main reducer gear and bearing wear, abnormal noise, insufficient lubrication of the main reducer, etc. , to achieve the effect of accurate inclination angle, convenient processing and simple base structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

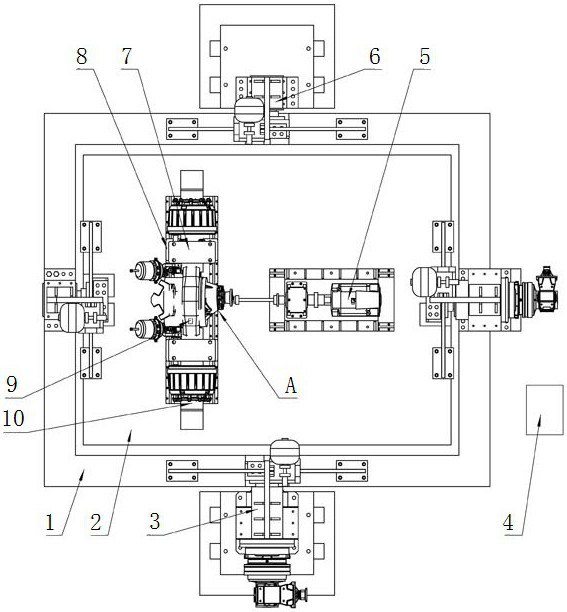

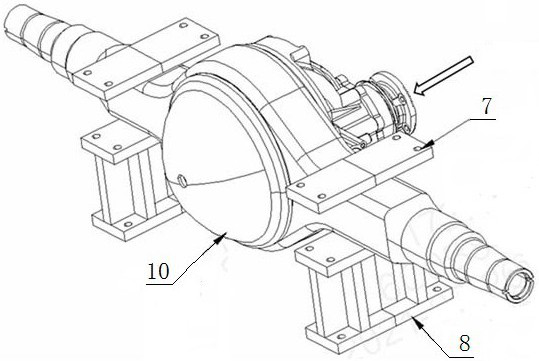

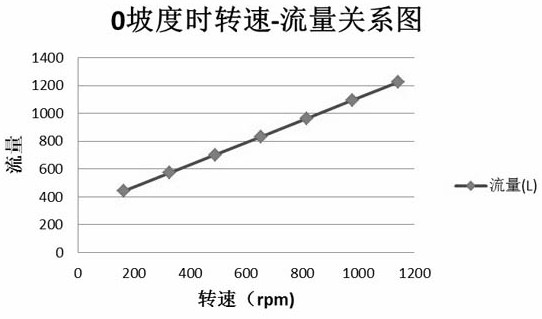

[0025] Such as figure 1 A drive axle main reducer lubrication test equipment is shown, the drive axle main reducer lubrication test equipment has a bench 2 mounted on a truss 1, and the truss 1 is equipped with a front and rear inclination control mechanism, which is used to adjust The angle at which the platform 2 is inclined backwards and forwards relative to the horizontal surface, the front and rear inclination control mechanism has a first inclination adjuster 3 and a second inclination adjuster 6 located on opposite sides of the truss 1, the first inclination adjuster 3 and the second inclination adjuster 6 Both come with inclination sensors. A motor 5, a vibration sensor 9, a base 8 and a clamping plate 7 for fixing the driving axle 10 are arranged on the stand 2, and the base 8 has two supporting blocks 8-1 arranged at intervals. The motor 5 has its own speed sensor and torque sensor, and the inclination control mechanism, the motor 5, and the vibration sensor 9 are c...

Embodiment 2

[0038] The differences between this embodiment and Embodiment 1 are: A. Installing the drive axle: Open the oil guide hole A of Φ12 in the middle of the oil return channel of the main reducer bearing seat of the drive axle 10 . All the other technical features are the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com