Method capable of clearly displaying carbide

A technology that clearly displays and carbides is applied in the preparation, sampling, and measuring devices of test samples. It can solve the problems of a large amount of time, accumulation of operating time, and inability to operate in batches at the same time, so as to improve efficiency and quality, and save energy. the effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

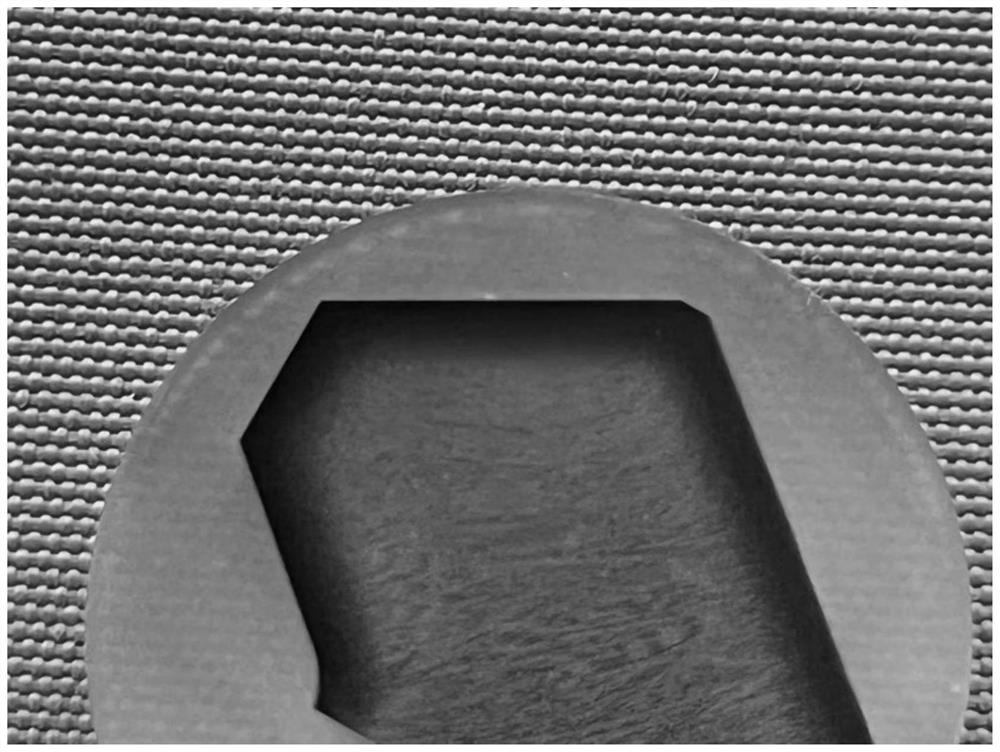

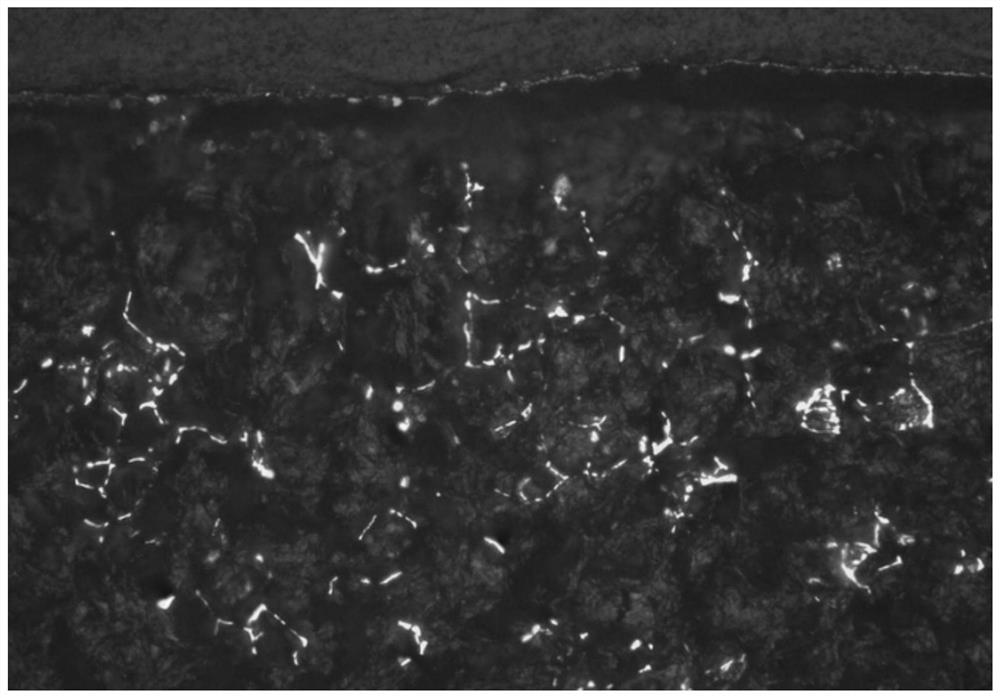

[0026] See attached Figures 1 to 3 As shown, a method for clearly displaying carbides in this embodiment includes the following steps:

[0027] S1: Grind and polish the sample 2 to be inspected until it becomes a mirror surface;

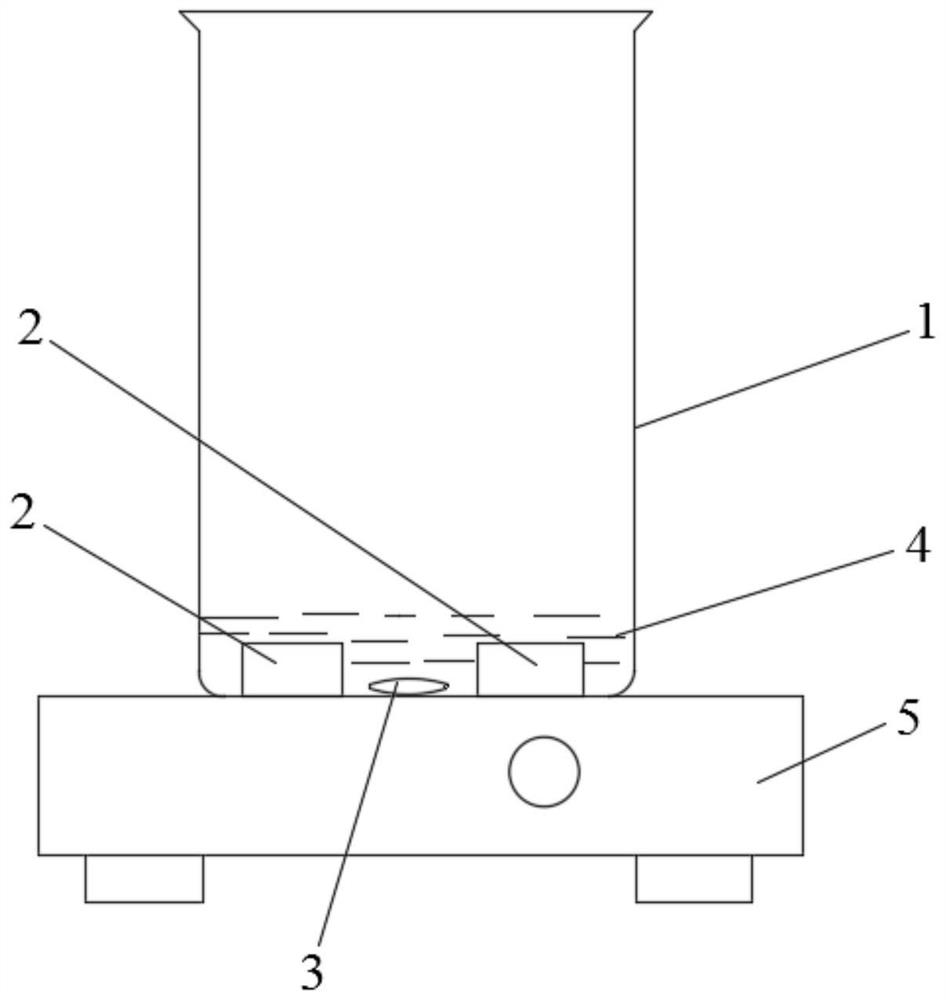

[0028] S2: Pour the nitric acid alcohol solution 4 into the beaker 1, put the magnetic stirrer rotor 3 into the beaker 1, and place the beaker 1 on the magnetic stirrer. Inspection sample 2 and magnetic stirrer rotor 3;

[0029] S3: Turn on the magnetic stirrer 5, and the magnetic stirrer 5 controls the nitric acid alcohol solution 4 to stir slowly, and puts a plurality of samples 2 to be tested facing up into the be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com