Preparation method of bipolar plate of fuel cell

A fuel cell and bipolar plate technology, which is applied to fuel cells, fuel cell components, circuits, etc., can solve the problems of large thickness, easy damage and high cost of bipolar plates, and achieve volume power density improvement, cost saving, The effect of high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

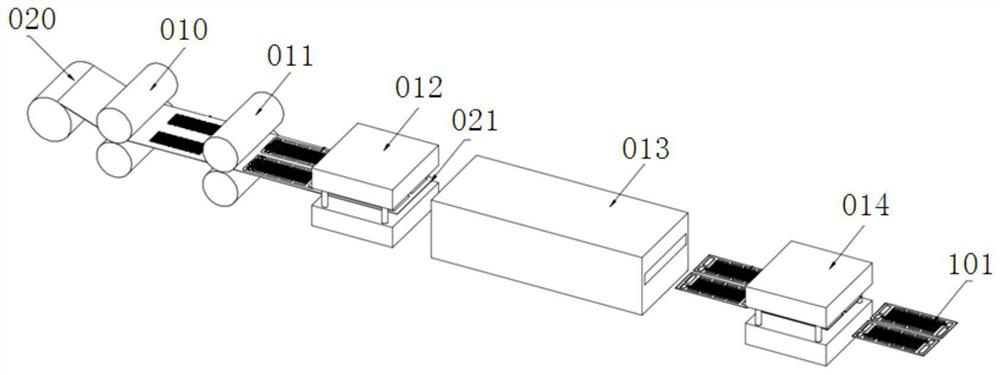

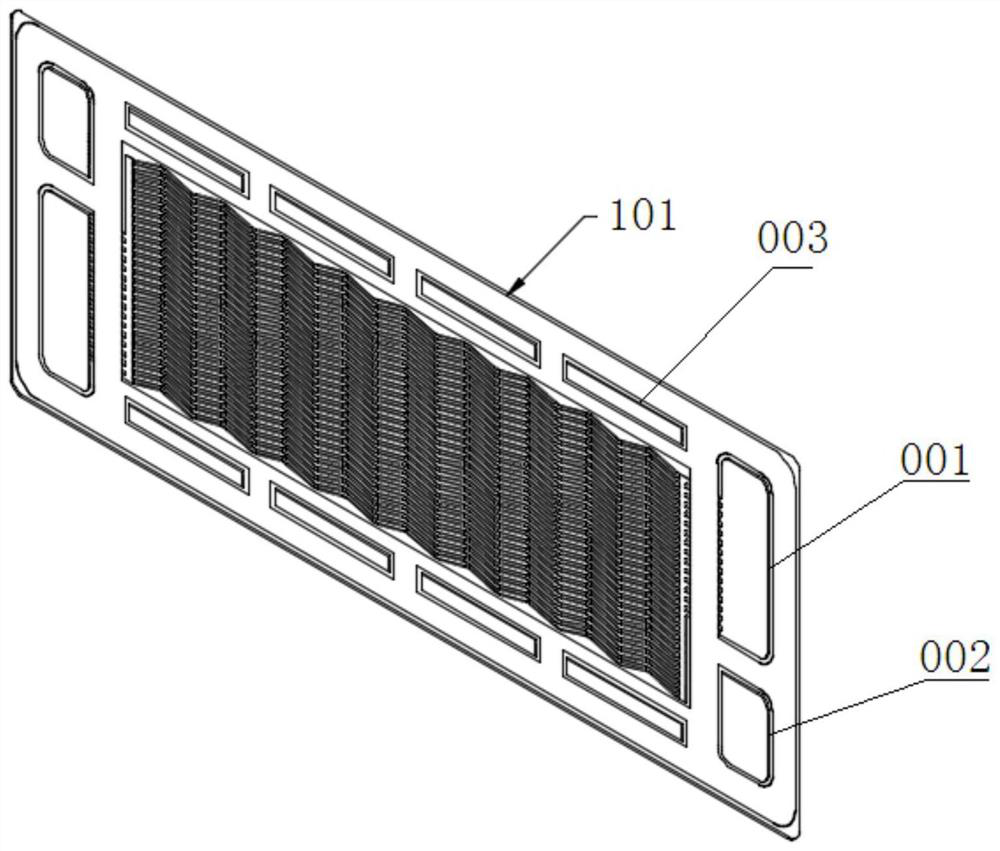

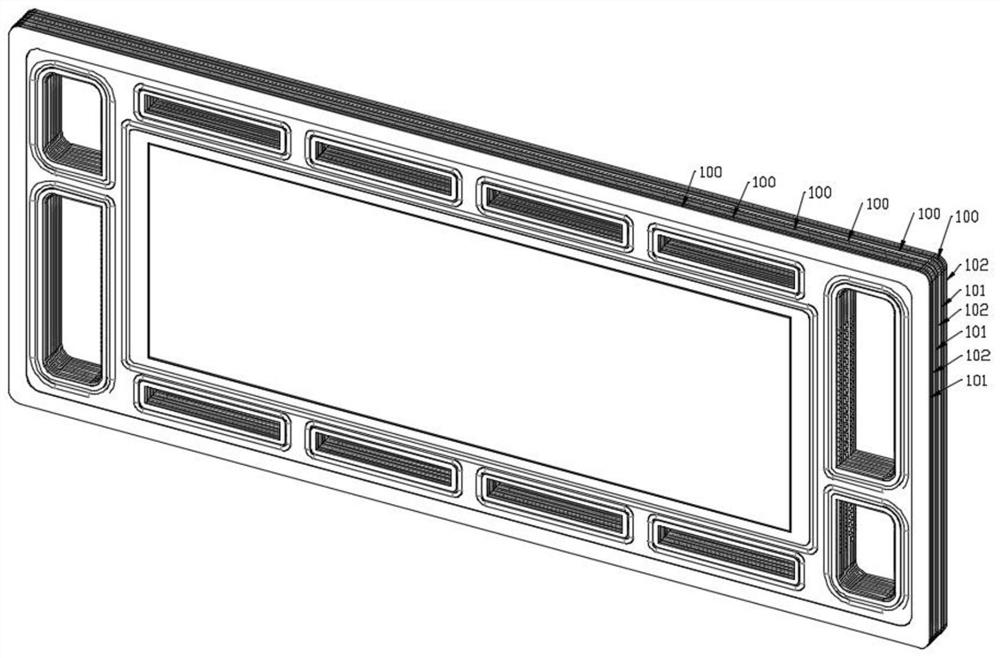

[0030] see figure 1 , 2 , the process flow of the fuel cell bipolar plate preparation method provided in this embodiment is as follows figure 1 As shown, the fuel cell bipolar plate 101 prepared by the fuel cell bipolar plate preparation method of this embodiment is as follows figure 2 As shown, the method includes the following steps in turn:

[0031] S1. Simultaneously carry out groove pre-rolling of the cathode flow field and anode flow field on both sides of the flexible graphite coil 020. The pre-rolling adopts the first rolling die 010 in the figure, and the initial thickness of the flexible graphite coil 020 is 1.5 -3.0mm, the thickness of the flexible graphite coil 020 after pre-rolling is reduced to 1.2-1.6mm, and the maximum depth of the grooves of the anode flow field and the cathode flow field formed by the pre-rolling of the flexible graphite coil 020 is 0.3 -0.5mm.

[0032] S2. Simultaneously carry out the second groove rolling of the cathode flow field and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com