Colored glass frits for automotive applications and related methods

A glass frit, 1mol% technology, applied in the field of colored glass frit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

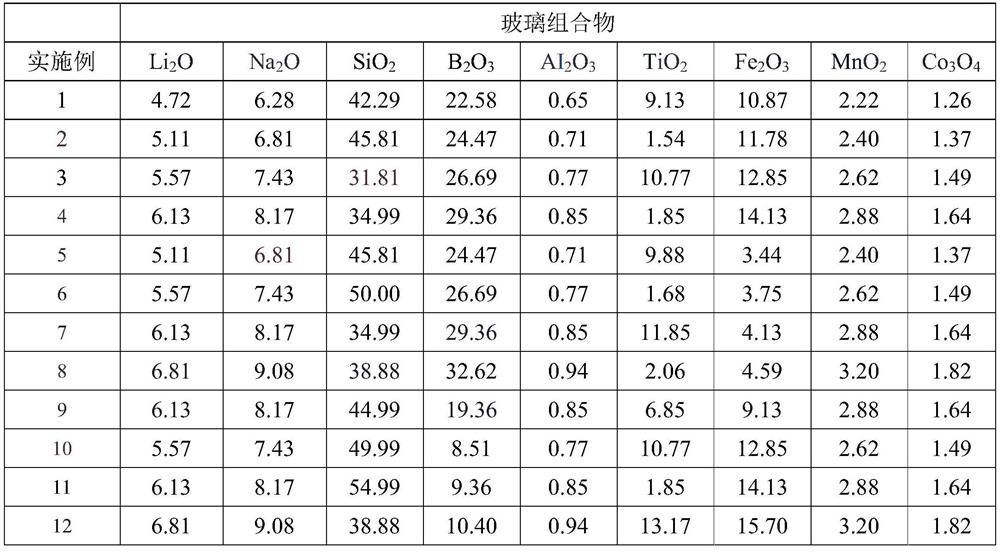

[0063] The following examples are provided to generally illustrate various embodiments in accordance with the present subject matter and should not be construed as limiting the invention.

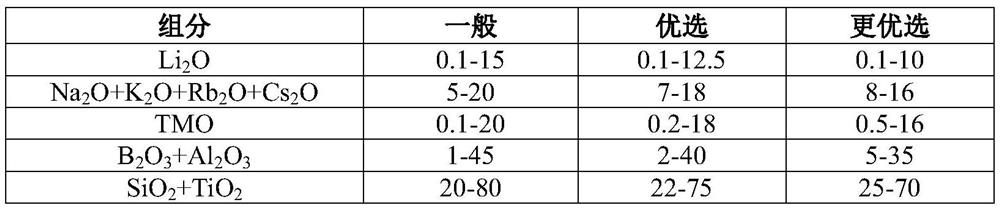

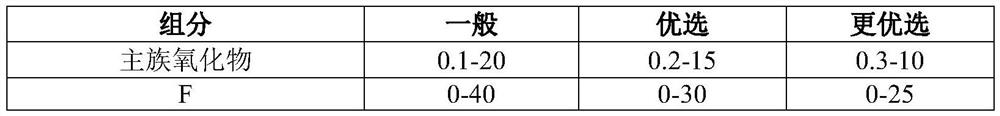

[0064] The following compositions represent exemplary embodiments of the subject matter. They exist to explain the subject in more detail, not to limit it. The subject glass frit compositions are shown in Tables 5, 7 and 9. In Tables 6, 8 and 9 the results of the following studies are shown.

[0065] Glass frits are made by mixing the raw materials shown in Tables 1-4 and are further described in this specification. The mixed raw meal components are melted at a temperature of 1350° C. to 1475° C. for about 45-90 minutes, and then subjected to quenching treatment, such as water or air quenching, or other methods known to those skilled in the art. The resulting frit is then ground to a fine particle size, preferably 2 to 6 microns using a ball mill. The finely ground glass powder is then ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com