Quantitative dispensing device for LED display module processing

A glue dispensing device and display module technology, which is applied to spraying devices, devices for coating liquid on the surface, cleaning methods and appliances, etc., can solve the problems of accelerating air flow on the surface of products, reducing waiting time, and accelerating glue fixation, etc. , to achieve the effect of reducing waiting time, reducing waiting time, and accelerating glue fixation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

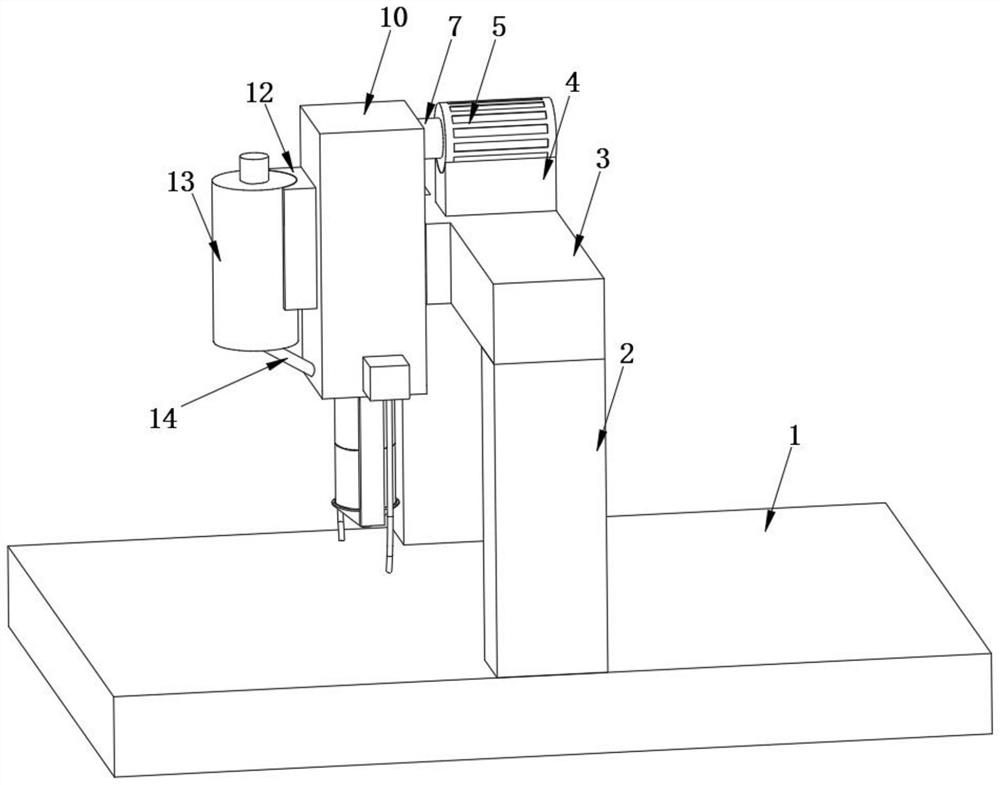

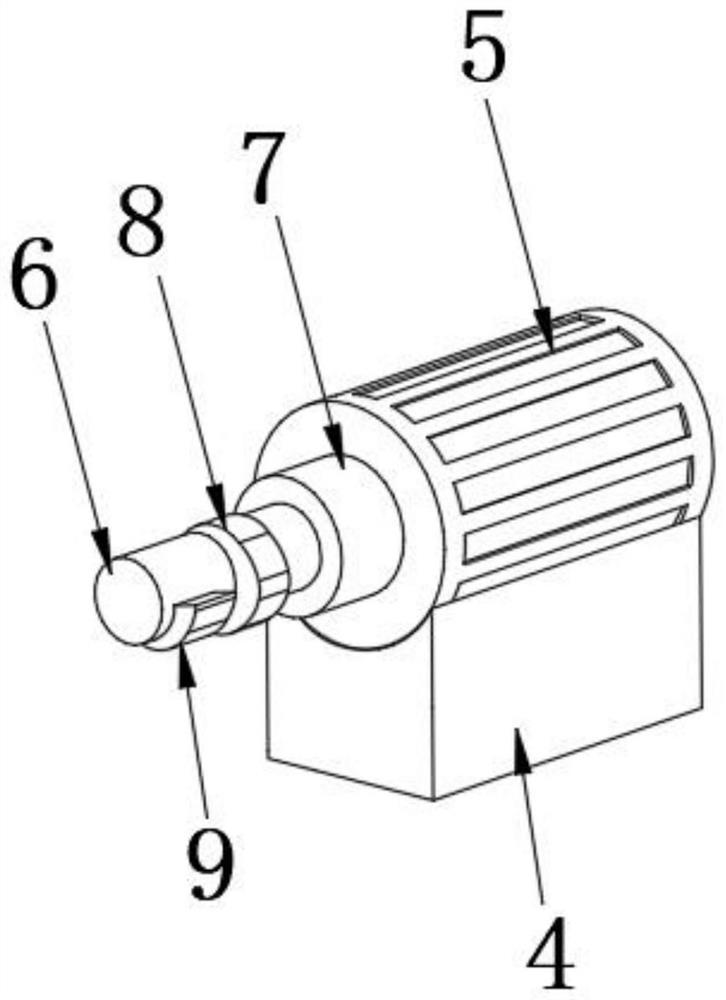

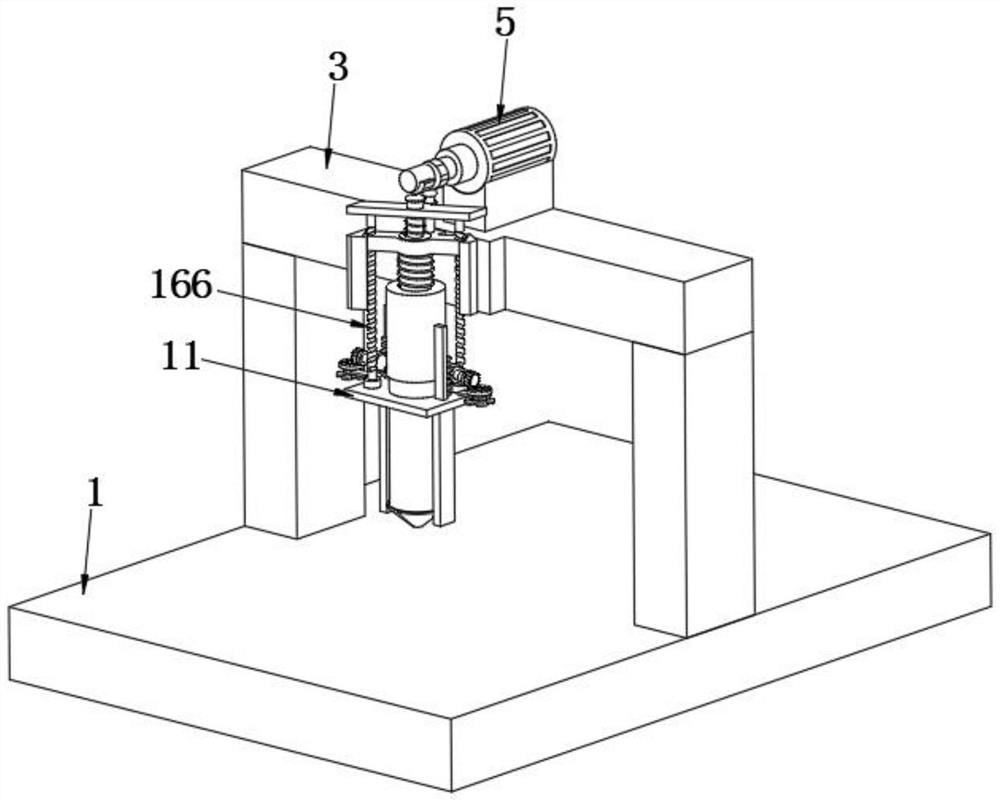

[0038] see Figure 1-9 As shown, the present invention is a quantitative dispensing device for LED display module processing, including a workbench 1, the upper surface of the workbench 1 is symmetrically fixedly connected with a support column 2, and the upper surface of the support column 2 is fixedly connected with a horizontal plate 3, The side of the horizontal plate 3 away from the support column 2 is fixedly connected with a support plate 4, and the support plate 4 is supported by the support column 2 and the horizontal plate 3, so that the servo motor 5 on the support plate 4 can work stably, and the servo motor 5 One side of the drive shaft 6 is rotationally connected with a protective cover 7, and when the servo motor 5 is working, the servo motor 5 drives the drive shaft 6 to rotate inside the protective cover 7, and the protection The cover 7 plays a protective role, avoiding external factors from causing damage to the drive shaft 6 and increasing the service life ...

Embodiment 2

[0042] Such as Figure 6 As shown, a driven mechanism 18 is fixedly connected to one side of the transmission gear 17, and the driven mechanism 18 includes a coaxial rod 181, that is, a coaxial rod 181 is fixedly connected to one side of the transmission gear 17, and the coaxial rod 181 is far away from the One end of transmission gear 17 is fixedly connected with bevel gear 1 182, and the outer surface of bevel gear 1 182 is meshed with bevel gear 2 183, and when transmission gear 17 rotates, the rotation of transmission gear 17 is divided into two types, one is point Rotation during gluing, the other is the rotation after dispensing, the rotation during dispensing, the transmission gear 17 drives the coaxial rod 181 to rotate, so that the coaxial rod 181 drives the bevel gear 182 to perform a circular rotation, and through The transmission between the gears makes the bevel gear 1 182 drive the bevel gear 2 183 to rotate in a circle, and the bevel gear 2 183 drives the driven...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com