Cantilever crane, overhead working truck and cantilever crane manufacturing method

A technology of jib frame and jib section, which is applied in the field of construction machinery, can solve problems such as crushing, buckling damage, unreasonable design of quadrilateral, pentagonal, hexagonal and U-shaped cross-sections, etc., to reduce weight and improve performance , The effect of stiffness improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0093] Combine below Figure 1 to Figure 15 The technical solution provided by the present invention is described in more detail.

[0094] see figure 1 , some embodiments of the present invention also provide an aerial work vehicle, including the jib provided by any technical solution of the present invention.

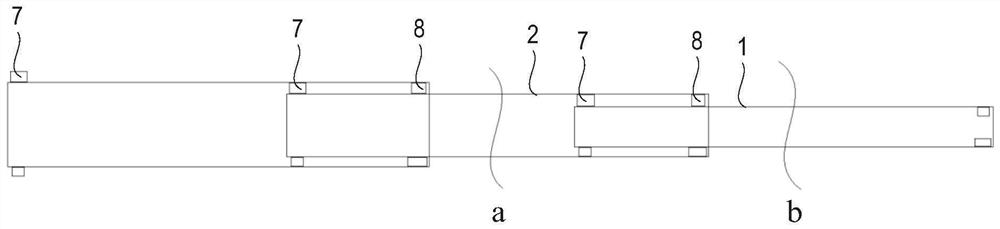

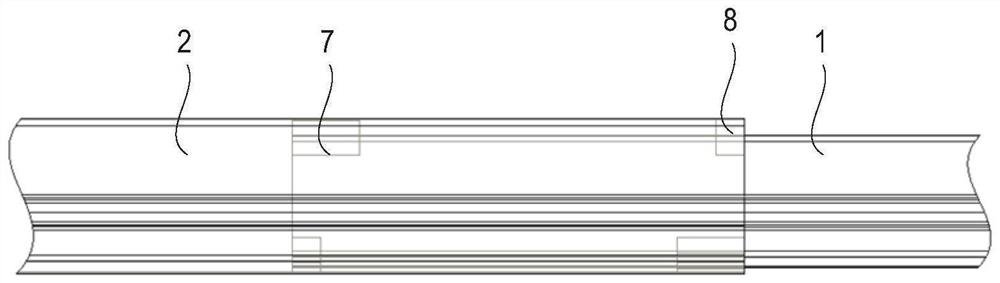

[0095] The number of jib sections included in the jib is 4 sections, 5 sections, 6 sections or even 7 sections. These boom sections are nested to form a telescoping boom. exist figure 1 A schematic diagram of the extended state of the three boom sections of the boom is shown in . exist figure 1 The region ab is indicated in . In order to illustrate the technical solutions of the embodiments of the present invention more clearly, the following description mainly focuses on the ab region in detail.

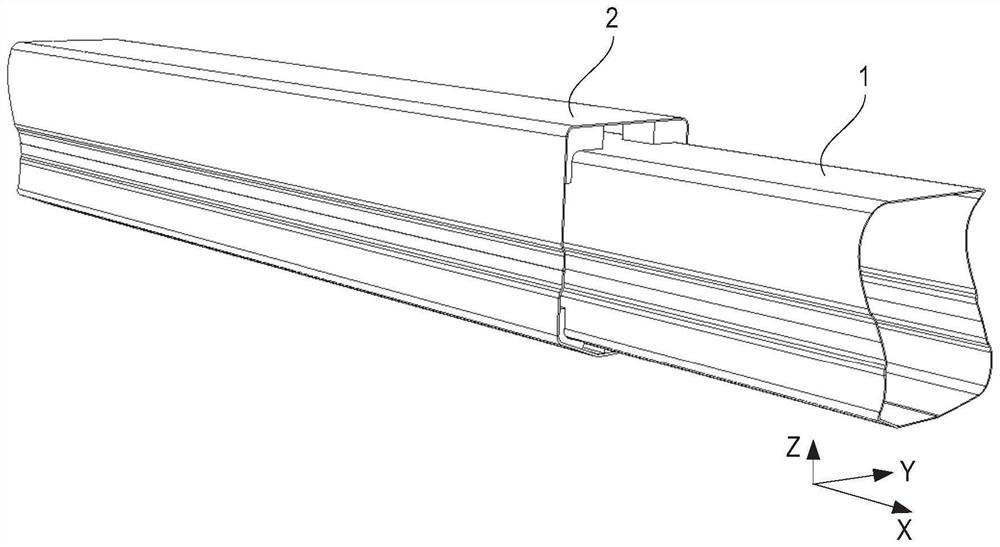

[0096] see Figure 2 to Figure 13 , some embodiments of the present invention provide a jib, especially suitable for blue plate aerial work vehicles. The blue plate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com