Bioengineering stirring kettle capable of preventing internal microorganisms from being damaged in stirring process

A bioengineering and stirring tank technology, applied in the field of bioengineering, can solve the problems of microbial damage, affect the reaction effect, affect the efficiency of the experiment, etc., and achieve the effect of easy adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

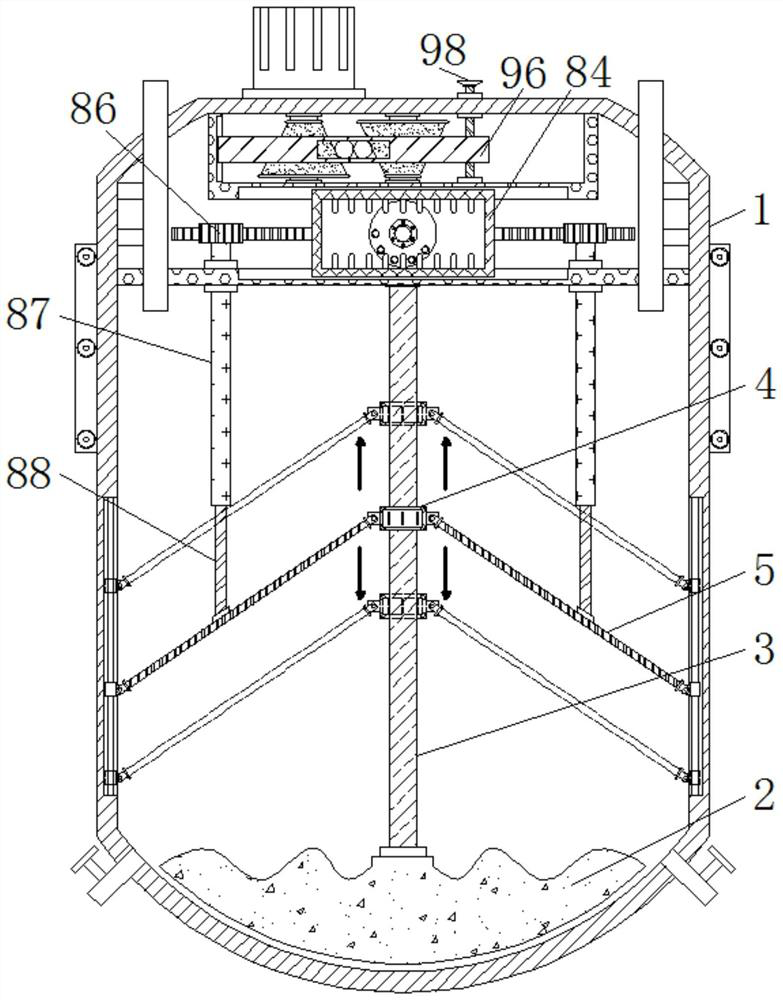

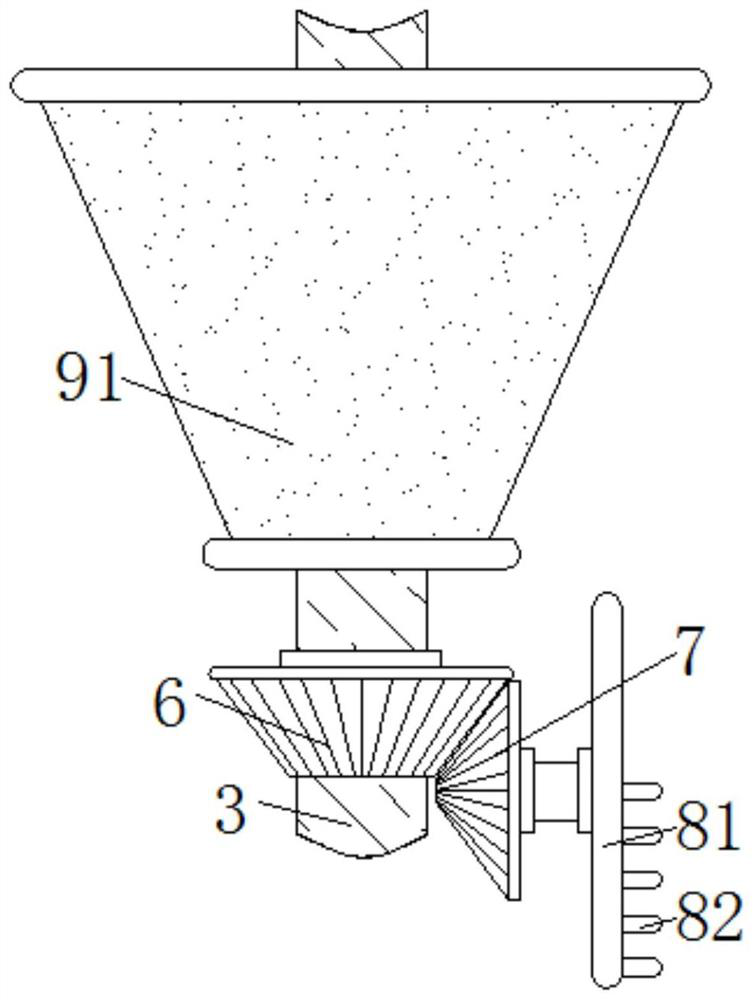

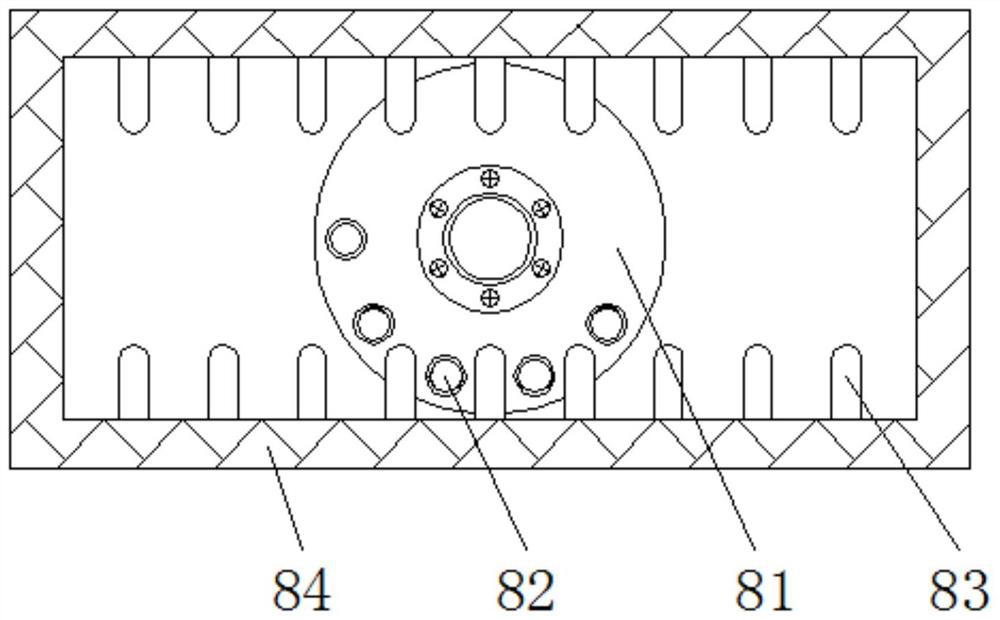

[0029] A bioengineering stirred tank for avoiding damage to internal microorganisms during the stirring process, comprising a furnace body 1, the bottom of the furnace body 1 is movably connected with an arc-shaped block 2, and the shape and size of the arc-shaped block 2 is the same as the bottom of the furnace body 1 The top of the arc-shaped block 2 is corrugated, the top of the arc-shaped block 2 is fixedly connected with a rotating rod 3, the outer wall of the rotating rod 3 is sleeved with a collar 4, and the right side of the collar 4 is riveted with a movable plate 5 The side of the movable plate 5 away from the rotating rod 3 is sleeved inside the furnace body 1, and the inside of the movable plate 5 is provided with a plurality of small holes, and the outer wall of the rotating rod 3 is fixedly connected with a driving gear 6, and the right side of the driving gear 6 The bottom meshing connection of the driven gear 7 is connected with a steering mechanism 8 on the rig...

Embodiment 2

[0032] A bioengineering stirred tank for avoiding damage to internal microorganisms during the stirring process, comprising a furnace body 1, the bottom of the furnace body 1 is movably connected with an arc-shaped block 2, and the shape and size of the arc-shaped block 2 is the same as the bottom of the furnace body 1 The top of the arc-shaped block 2 is corrugated, the top of the arc-shaped block 2 is fixedly connected with a rotating rod 3, the outer wall of the rotating rod 3 is sleeved with a collar 4, and the right side of the collar 4 is riveted with a movable plate 5 The side of the movable plate 5 away from the rotating rod 3 is sleeved inside the furnace body 1, and the inside of the movable plate 5 is provided with a plurality of small holes, and the outer wall of the rotating rod 3 is fixedly connected with the driving gear 6, and the right side of the driving gear 6 The bottom meshing connection of the driven gear 7 is connected with a steering mechanism 8 on the r...

Embodiment 3

[0035]A bioengineering stirred tank for avoiding damage to internal microorganisms during the stirring process, comprising a furnace body 1, the bottom of the furnace body 1 is movably connected with an arc-shaped block 2, and the shape and size of the arc-shaped block 2 is the same as the bottom of the furnace body 1 The top of the arc-shaped block 2 is corrugated, the top of the arc-shaped block 2 is fixedly connected with a rotating rod 3, the outer wall of the rotating rod 3 is sleeved with a collar 4, and the right side of the collar 4 is riveted with a movable plate 5 The side of the movable plate 5 away from the rotating rod 3 is sleeved inside the furnace body 1, and the inside of the movable plate 5 is provided with a plurality of small holes, and the outer wall of the rotating rod 3 is fixedly connected with the driving gear 6, and the right side of the driving gear 6 The bottom meshing connection of the driven gear 7 is connected with a steering mechanism 8 on the ri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com