Structural process method of weft knitting integrally-formed close-fitting electrode

A process method and electrode technology, applied in weft knitting, textiles, papermaking, knitting, etc., can solve problems such as different curvature, small stretching range, and influence on precision, achieve small deformation or displacement, and improve wearing comfort , the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

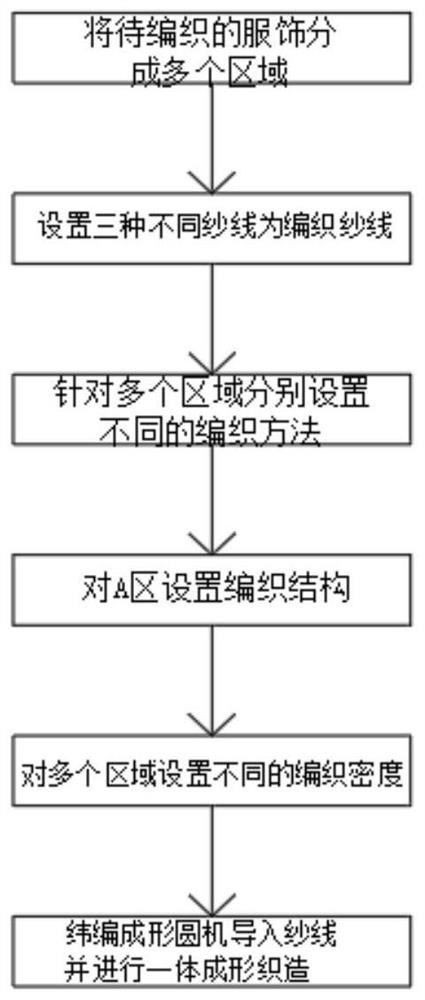

[0053] Such as figure 1 As shown, the present invention proposes a structural process method of weft knitting integrally forming a close-fitting electrode, so that the sensing area where the electrode is located and the non-sensing area where the monitoring clothing is located are integrally woven, including the following steps:

[0054] S1. Dividing the clothing to be knitted into multiple regions;

[0055] S2, setting three different yarns as knitting yarns;

[0056] S3. Setting different weaving methods for multiple regions;

[0057] S4, setting an electrode weaving structure on the A area;

[0058] S5. Setting different weaving densities for multiple regions;

[0059] S6. The circular knitting machine for weft knitting introduces yarns and performs integral forming and weaving.

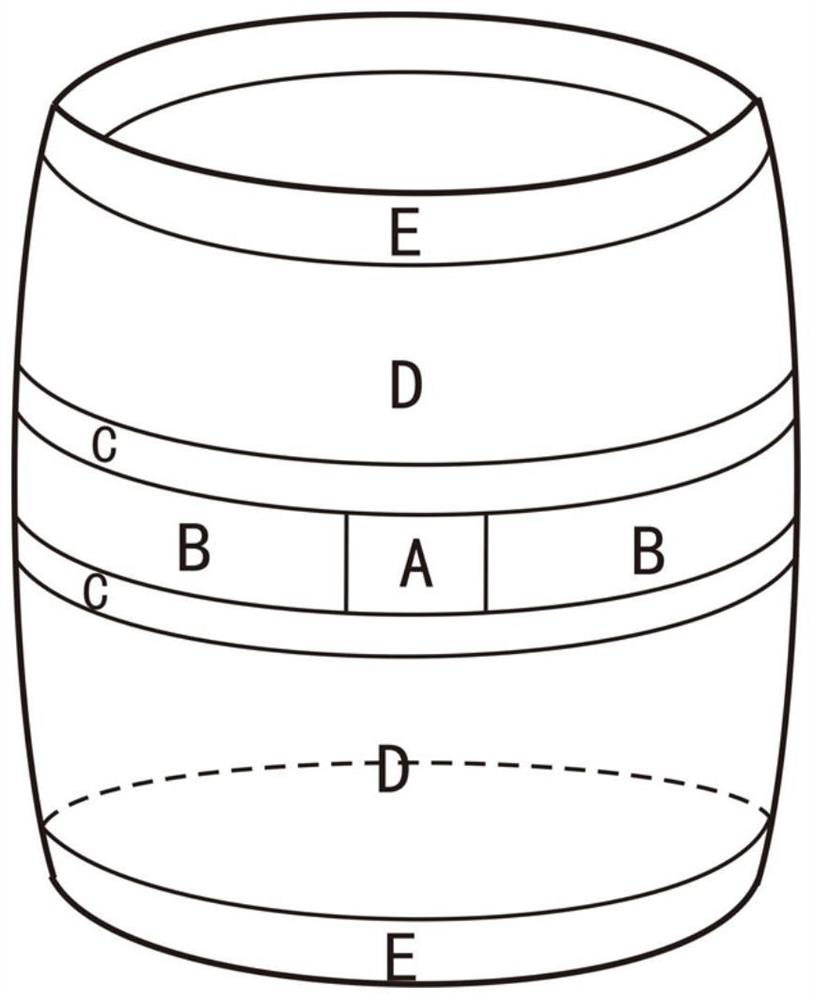

[0060] In this embodiment, the division of regions in step S1 is based on the electrode sensing area and the non-electrode sensing area, such as figure 2 As shown, the electrode sensing area...

Embodiment 2

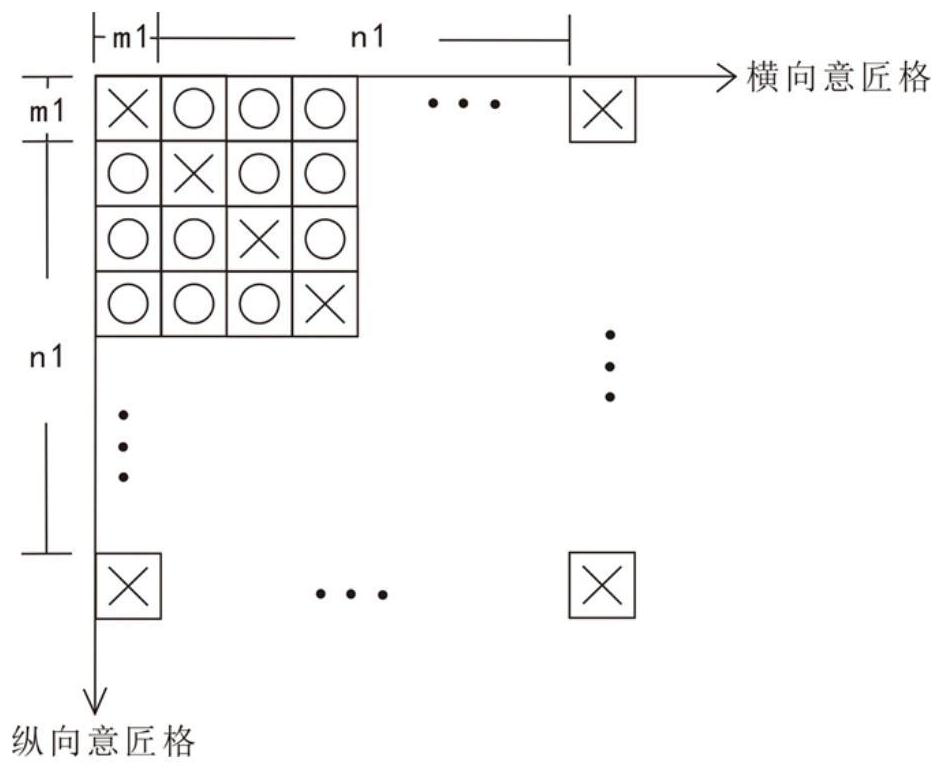

[0071] This embodiment proposes a convex electrode design for the electrode weaving structure in area A, and its structure is shown in the figure image 3 Shown, in the figure with "×" means: the knitting needle hooks the third yarn as the veil and the second yarn as the ground yarn together to form a loop, the first yarn exists in the form of floating thread; in the figure as "○" means: the knitting needle hooks the first yarn as the veil and the second yarn as the ground yarn to form a loop, and the third yarn exists in the form of a float. The design method of the convex electrode is as follows: in each knitting row, set m1 needles to hook the third yarn to form a loop, m1≥1, set n1 needles to hook the first yarn to form a loop, n1≤9, m1+ N1 coil structures are knitted horizontally and circularly. When weaving a new row, the coil structure of the new row moves one coil position along the knitting direction as a whole. The crafting front of each row is m1 third yarn coils an...

Embodiment 3

[0080] This embodiment proposes a design of concave-convex electrodes for the weaving structure of the A area. The design method of the weaving structure of the concave-convex electrodes is: A area is provided with a knitting area of (m2+2*n2)*H coils, and m2 is the first row of each row. The number of three yarn coils, m2≤12, 2*n2 is the number of the first yarn coils in each row, n2≥1, the first yarn coils are respectively set at the knitting start position and knitting position of each row in the A area Termination position, H is the number of knitting rows in the A area, the third yarn is distributed in blocks on the technical front of the A area, the first yarn is a frame surrounding the third yarn on the technical front of the A area, the first yarn The line exists in the form of a long convex line on the reverse side of the process in the A area. Its structural meaning is as follows Figure 7 Shown, in the figure with "×" means: the knitting needle hooks the third ya...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com