Automobile headlamp steering follow-up device and follow-up method thereof

A technology of a follow-up device and headlight, which is applied in the field of vehicle engineering, can solve the problems of complex follow-up structure of the headlight, the light cannot illuminate the front, and it is unfavorable for wide application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

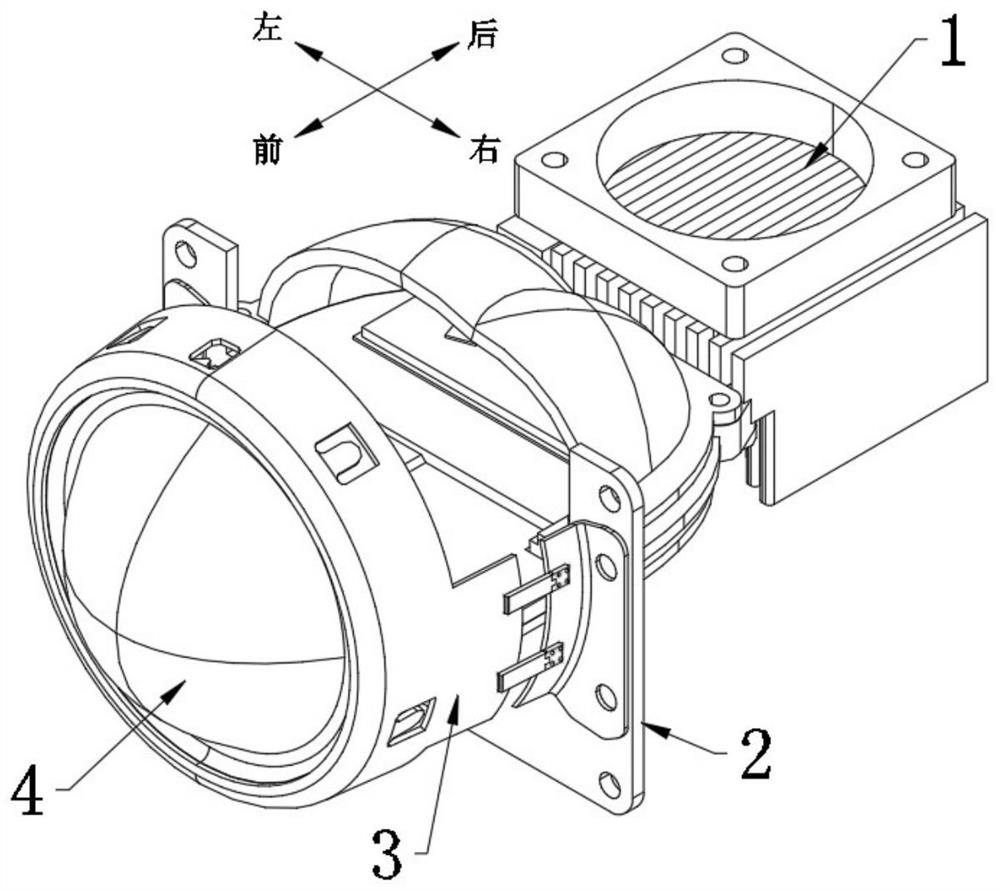

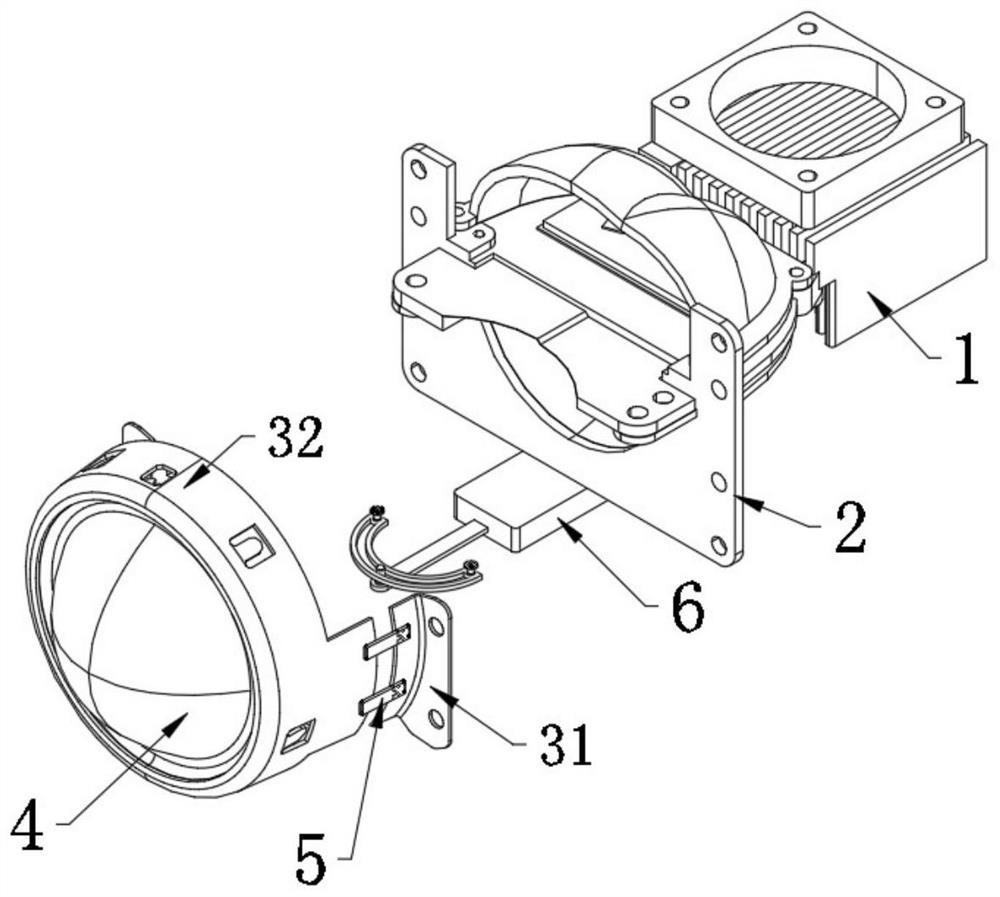

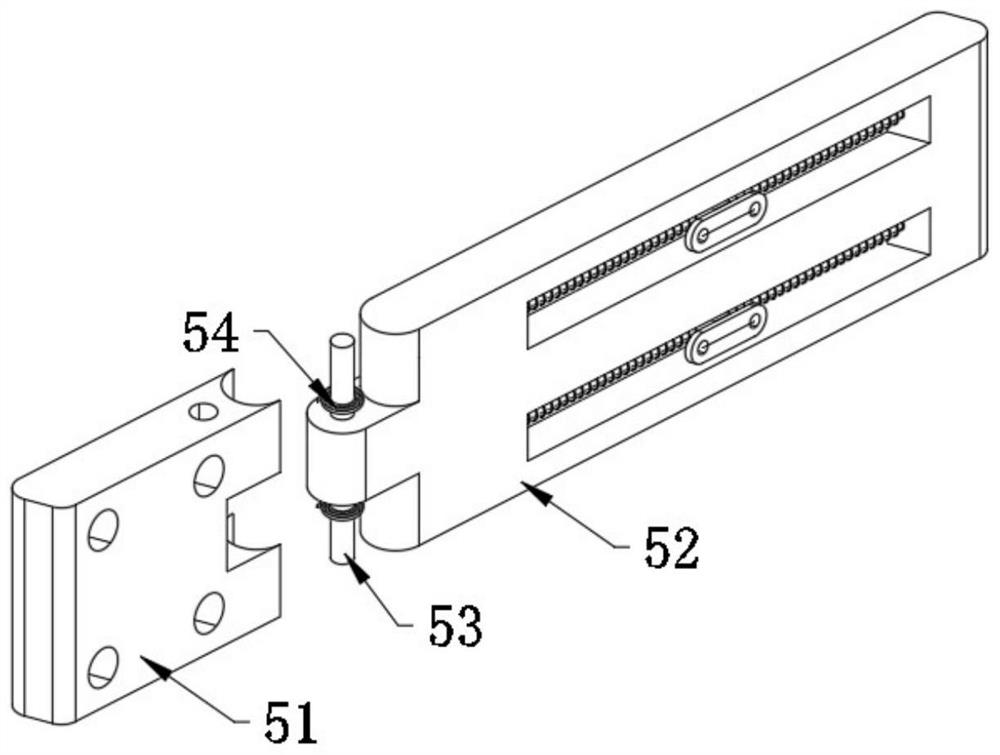

[0029] refer to Figure 1-7 In this embodiment, a steering follower for automobile headlights is proposed, including a headlight main body 1 and a lens 4, a mounting plate 2 is fixedly installed on one side of the headlight main body 1, and a fixing frame 3 is fixedly installed on the lens 4, The fixed frame 3 and the mounting plate 2 are fixedly connected together, the fixed frame 3 includes an annular sleeve 32 fixedly sleeved on the lens 4, and the side of the annular sleeve 32 near the mounting plate 2 is movably connected with two mounting frames 31, the mounting frame 31 There are two flexible support mechanisms 5 connected between the ring sleeve 32, and the two mounting brackets 31 are fixedly connected with the installation plate 2. The bottom of the headlight main body 1 is fixedly equipped with a swing mechanism 6, the swing mechanism 6 and the ring sleeve 32. Activities are linked together.

[0030] Specifically, during the turning process of the vehicle, the swin...

Embodiment 2

[0045] A steering follow-up method for automobile headlights, which is applied to any one of the above-mentioned steering follow-up devices for headlights, comprising the following steps:

[0046] S1. A sensor is installed on the steering gear of the car. During the turning process of the vehicle, the ECU receives the signal of the sensor and processes it and sends an instruction to the swing mechanism 6. Therefore, during the turning process of the vehicle, the swing mechanism 6 drives the lens 4 to The turning direction moves synchronously, and the turning speed of the lens 4 is equal to the turning speed of the vehicle. During the turning process of the vehicle, the headlights are dynamically adjusted to adapt to the current steering angle and keep the light direction consistent with the current driving direction of the car ;

[0047] During the steering process, four sets of flexible supporting mechanisms 5 are used to make flexible connections between the mounting plate 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com