Asymmetric micro-cavity edge emitting semiconductor laser array

A laser array, laser technology, applied in semiconductor laser devices, laser devices, structures of optical resonators, etc., to achieve the effects of good heat dissipation, easy output coupling, and consistent light output directions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

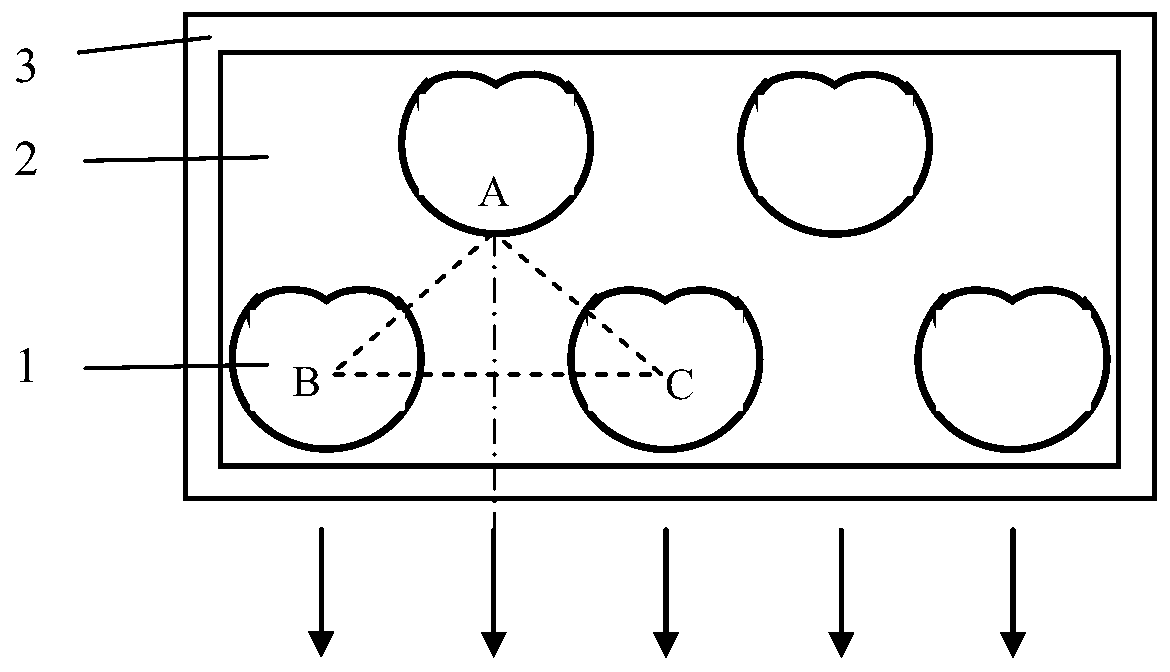

[0014] The number of single laser tubes in the front row of laser lines and the rear row of laser lines is 4, such as figure 2 As shown, the asymmetric microdisk cavity is a snail-shaped microdisk cavity, and the snail polar coordinate equation of the snail-shaped microdisk cavity is ρ(θ)=ρ 0 (1+εcosθ), where ρ(θ) is the polar diameter, ρ 0 is the characteristic radius, θ is the polar angle, ε is the deformation factor, and ρ 0 As the characteristic radius of the snail-shaped microdisk cavity, take ρ 0 = 150 μm, ε = 0.42. The distances AB and AC between the light-emitting point A of the single laser tube in the rear row of laser lines and the geometric centers B and C of the two closest laser single tubes in the front row of laser lines are equal, and the angle between AB and AC is ∠ A=120°, AB=AC=500μm, from this, it can be calculated that the geometric center distance of two adjacent laser single tubes in the front row of laser lines is about 850μm, which offsets the cha...

Embodiment 2

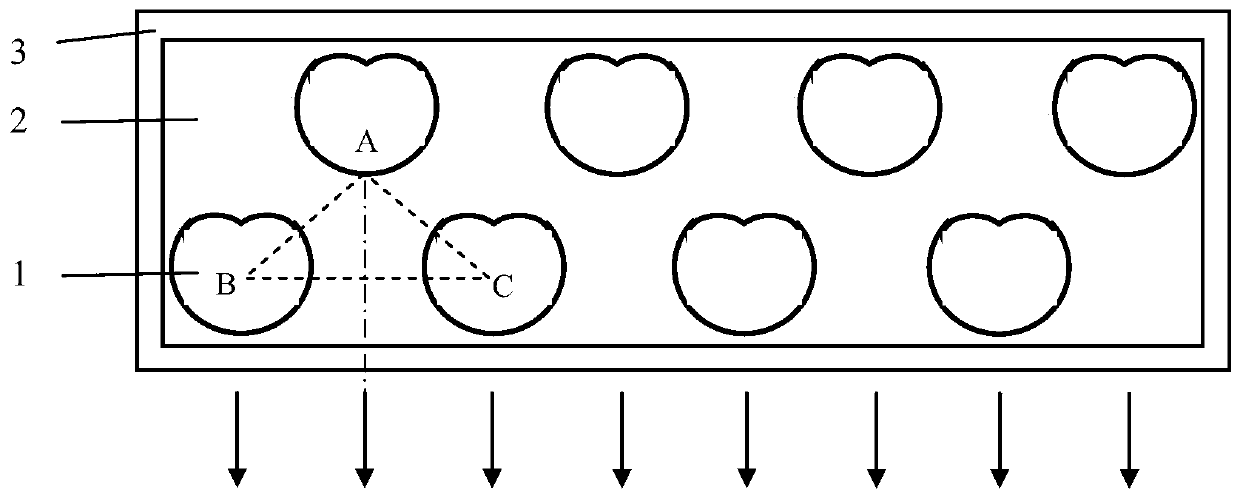

[0016] The number of single laser tubes in the front row of laser lines is 3, and the number of single laser tubes in the rear row of laser lines is 2, such as image 3 As shown, the asymmetric microdisk cavity is an elliptical microdisk cavity, the ellipse deformation factor ε is defined as the ratio of the long axis and the short axis of the ellipse, the deformation factor ε=1.2, and the length of the short axis is 120 μm. The distances AB and AC between the light-emitting point A of the single laser tube in the rear row of laser lines and the geometric centers B and C of the two closest laser single tubes in the front row of laser lines are equal, and the angle between AB and AC is ∠ A=60°, AB=AC=500μm, from this, it can be calculated that the geometric center distance of two adjacent laser single tubes in the front row of laser lines is about 500μm, which offsets the lateral radius of the two elliptical microdisk cavity cavities, The lateral radius of the cavity is also th...

Embodiment 3

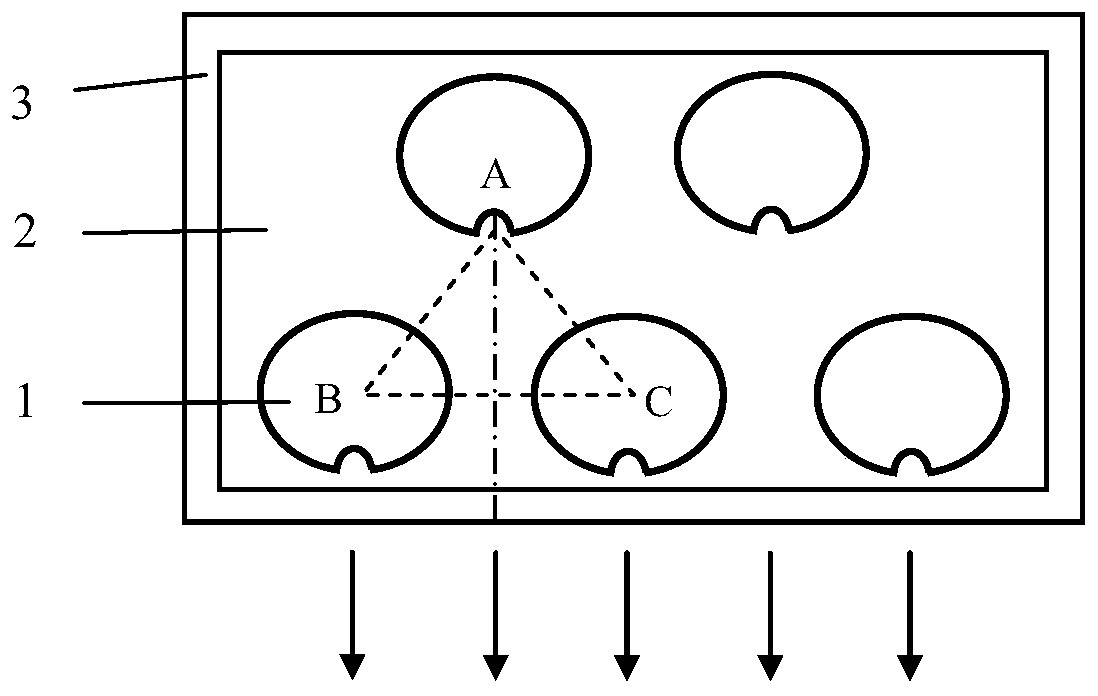

[0018] The number of single laser tubes in the front row of laser lines is 3, and the number of single laser tubes in the rear row of laser lines is 2, such as Figure 4 As shown, the asymmetric microdisk cavity is a helical microdisk cavity, and the helical polar coordinate equation of the helical microdisk cavity is where ρ(θ) is the polar diameter, ρ 0 is the characteristic radius, θ is the polar angle, ε is the deformation factor, and ρ 0 As the characteristic radius of the helical microdisk cavity, take ρ 0= 200 μm, ε = 0.1. The distances AB and AC between the light emitting point A of the single laser tube in the rear row of laser lines and the geometric centers B and C of the two closest laser single tubes in the front row of laser lines are equal, and the angle between AB and AC is ∠ A=90°, AB=AC=900μm, from this, it can be calculated that the geometric center distance of two adjacent laser single tubes in the front row of laser lines is about 1270μm, which offsets...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com