Method for recycling agglomerated or hardened jelly formed in positive electrode gel preparation process

A technology of jelly and positive electrode, which is applied in the direction of battery electrodes, structural parts, final product manufacturing, etc., can solve problems such as waste, and achieve the effect of low cost and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

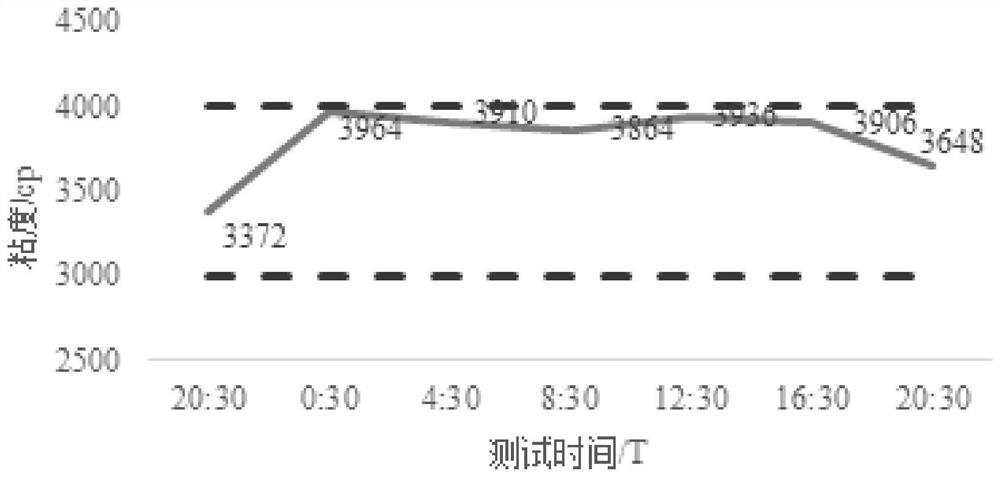

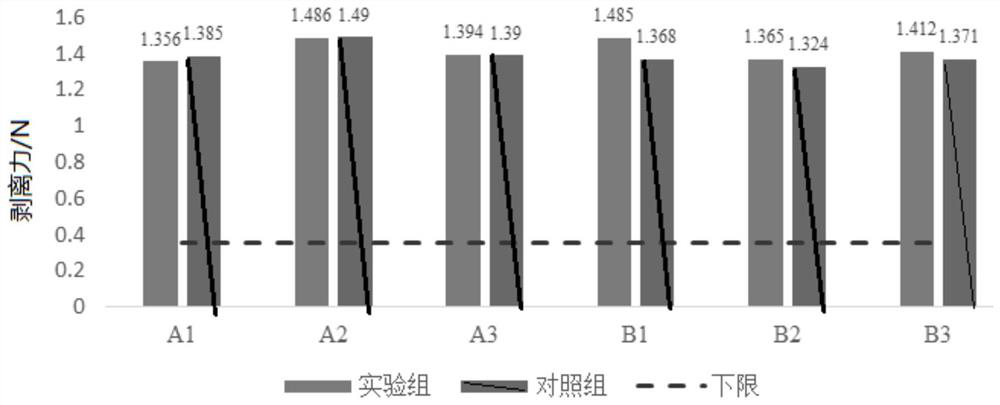

Embodiment 1

[0038] This embodiment provides a method for recycling and utilizing the anode gel making process to form agglomerated or plated jelly, the method includes the following steps:

[0039] (1) Cut the collected agglomerated or plate-like jelly into 6cm in size with a ceramic knife 2 The small piece, weigh 55kg, put it into a 1000L stainless steel stirring tank, add 850kg N-methylpyrrolidone (NMP) and 5.02kg n-propanol to the stainless steel stirring tank, set the temperature of the stirring tank to 50°C, and the vacuum Set it to -80kPa, set the stirring speed to 25rpm, the dispersion speed to 1200rpm, stir and disperse for 4h, m1 / (m1+m2)=6%, m3 / (m1+m2+m3)=0.55%;

[0040] (2) stop dispersing, cool to 23 ℃, break the vacuum, take a sample to detect the solid content of the glue, the measured value is 5.13%;

[0041] (3) Add 8.33kg of PVDF powder, set the temperature of the mixing tank to 50°C, set the vacuum degree to -80kPa, and the dispersion speed to 1200rpm, stir and disperse ...

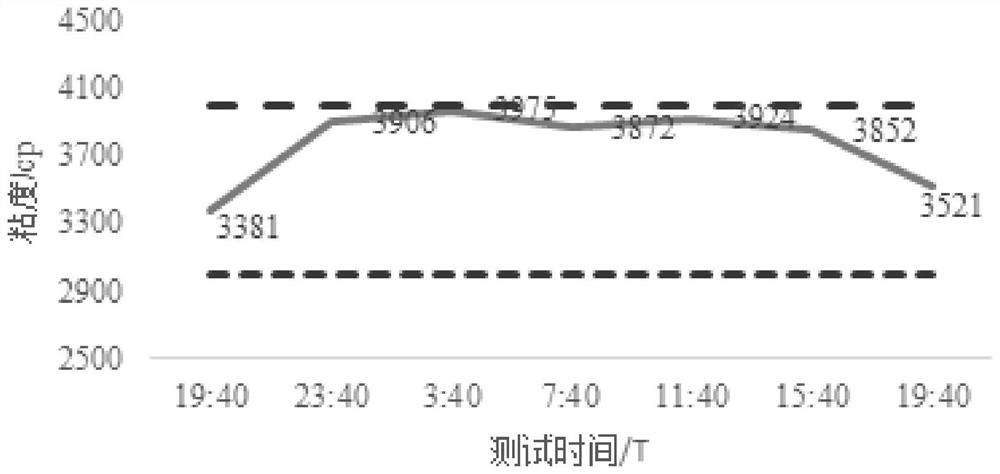

Embodiment 2

[0043] This embodiment provides a method for recycling and utilizing the anode gel making process to form agglomerated or plated jelly, the method includes the following steps:

[0044] (1) Cut the collected agglomerated or plate-like jelly into 8cm in size with a ceramic knife 2 60kg, put into a 1000L volume stainless steel mixing tank, add 800kg N-methylpyrrolidone (NMP) and 5kg n-propanol to the stainless steel mixing tank, set the temperature of the mixing tank at 50°C, and set the vacuum -80kPa, the stirring speed is set to 25rpm, the dispersion speed is 1200rpm, stirring and dispersing for 4h, m1 / (m1+m2)=7%, m3 / (m1+m2+m3)=0.58%;

[0045] (2) Stop the dispersion, cool to 23°C, break the vacuum, take a sample to detect the solid content of the glue, and the measured value is 5.25%;

[0046] (3) Add 7.56kg of PVDF powder, set the temperature of the mixing tank to 50°C, set the vacuum degree to -80kPa, and the dispersion speed to 1200rpm, stir and disperse for 2 hours, stop t...

Embodiment 3

[0048] The only difference between this embodiment and embodiment 1 is that the quality of NMP described in step (1) is 600kg, and other conditions and parameters are exactly the same as embodiment 1, m1 / (m1+m2)=8.3%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com