Method for removing spores from raw goat milk, method for preparing purified goat milk, produced goat milk and use thereof, and cheese production method

A technology of goat milk and spores, which is applied to milk preparations, milk preservation, milk processing equipment, etc., can solve the problems of impossible production of goat milk and inability to eliminate the limitation of goat milk components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

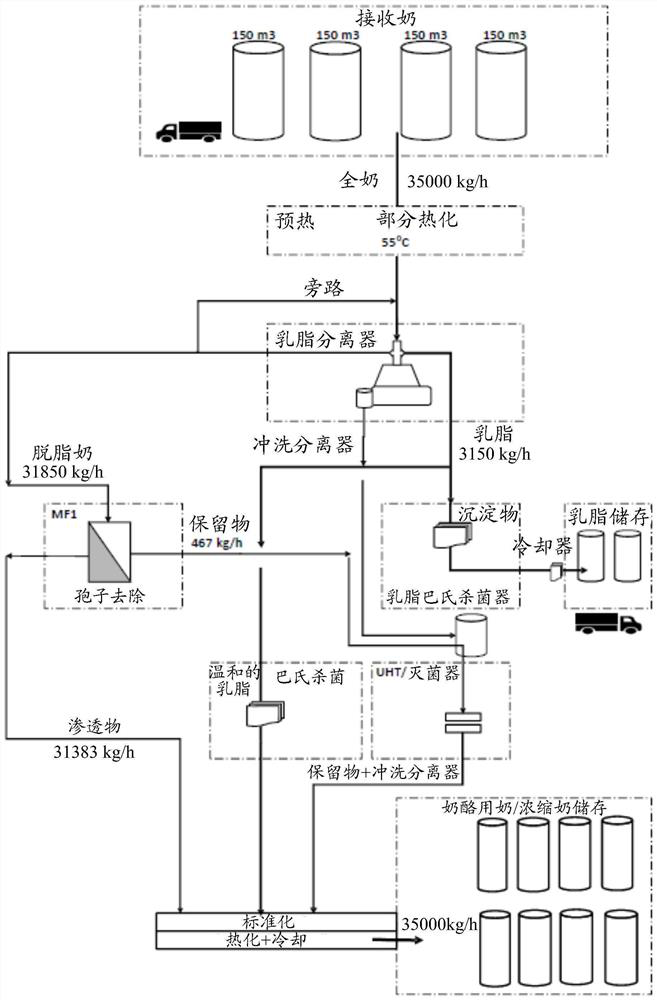

[0063] figure 1 An example of an overall process for making purified goat milk suitable for use as cheese milk according to the invention is illustrated. The milk was preheated at 55°C in mild pasteurized form and fed to the creamer. The desired portion of the cream thus obtained is sent to a gentle cream pasteurization process and is kept in the process. The remainder of the cream is sent to another cream pasteurizer for separate storage of the goat cream. Creamers are open centrifuges that have a flow rate twice that of the one into which the raw milk is fed. A corresponding additional milk flow into the separator is provided by a bypass in the line from the separator to subsequent treatment. Via this bypass, the skim milk is recirculated into the cream separator. After passing twice through the cream separator, the skimmed milk is directed to subsequent processing and thus fed into the microfiltration unit MF1. This results in spore removal, thereby obtaining a spore-...

Embodiment 2

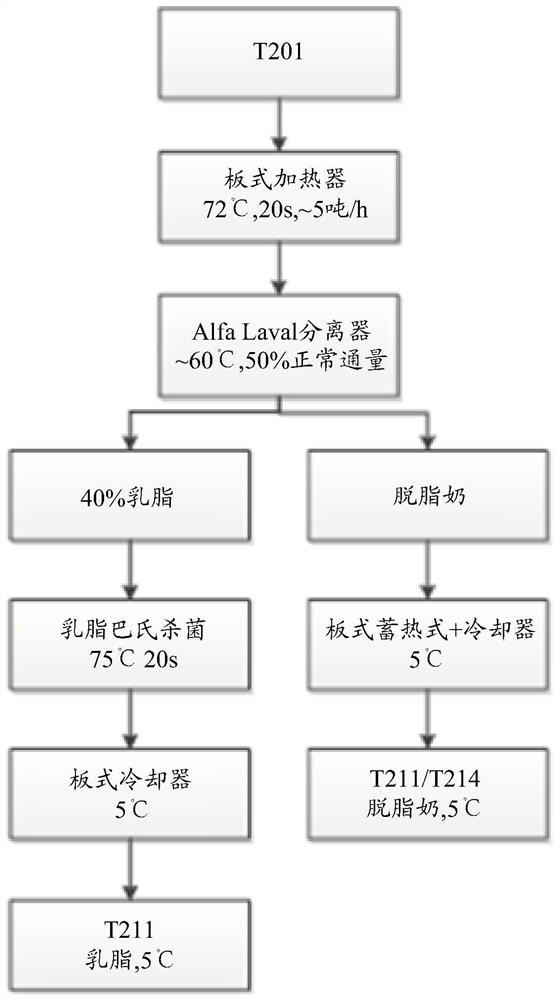

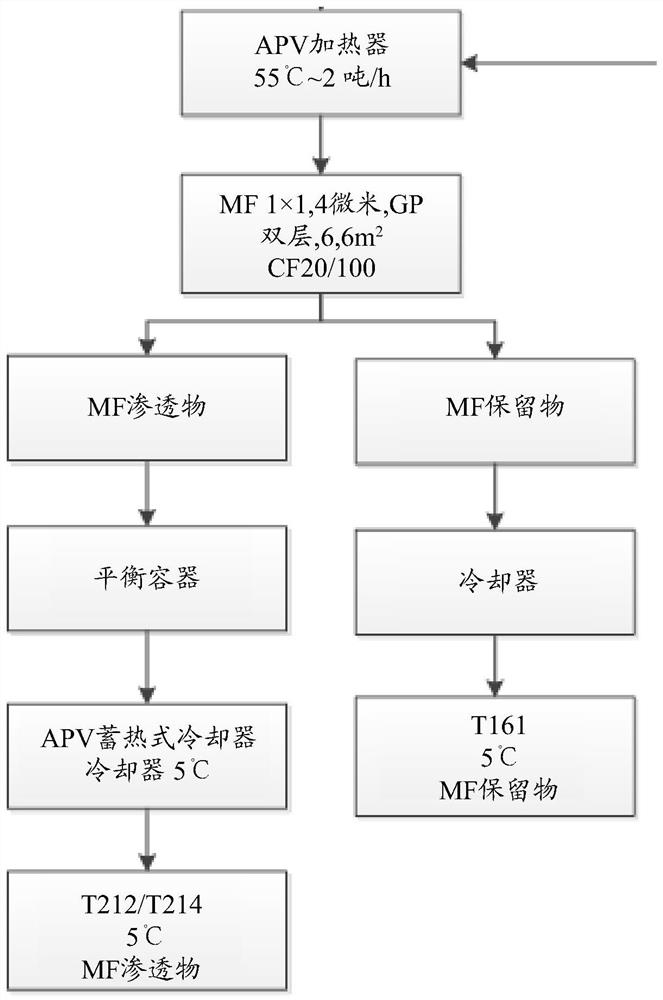

[0065] This example follows figure 2 -Scheme shown in 4. After receiving raw goat milk, the milk is gently pasteurized and defatted according to authoritative regulations ( figure 2 ). The skim milk is thus fed into the centrifuge at half the rate to allow for more efficient skimming, resulting in skim milk with a lower fat content. After skimming, the milk is microfiltered (1.4 μm MWCO) to remove bacteria and spores ( image 3 , the arrow towards the APV heater indicates the supply of skim milk). The milk fat is sterilized alone and the MF retentate is combined with the heavy fraction from milk fat separation and sterilized by heat treatment (yielding a sterilized retentate). The resulting MF permeate, cell-free milk, is reconstituted with butterfat and sterilized retentate and standardized to the desired fat / protein ratio, yielding purified goat's milk suitable for cheese production.

Embodiment 3

[0067] The cheese-making process was performed on purified goat's milk obtained by the process described in Example 1. So the milk is pumped into the curd tank, the fermenters and calcium chloride are added. Subsequently, when the desired state of acidification has been achieved, rennet is added to induce coagulation, producing curds. Cut the curd into pieces and wash with warm water. The resulting curds and whey are drained to separate the curds and whey. Transfer the curds to cheese jars and thus press into molds. The pressure is gradually increased to form a closed crust and release more whey. Finally, the resulting molded cheese is brine-cured and ripened on wooden racks.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com