Continuous method SAN resin production method based on plug flow reactor

A plug-flow reactor and production method technology, applied in chemical instruments and methods, chemical/physical/physicochemical fixed reactors, feeding devices, etc., can solve the problem of low polymerization conversion rate, mass transfer and heat transfer Problems such as difficult control and low production efficiency can be achieved to achieve the effect of ensuring fullness and comprehensiveness, improving reaction production speed, and ensuring comprehensiveness of reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

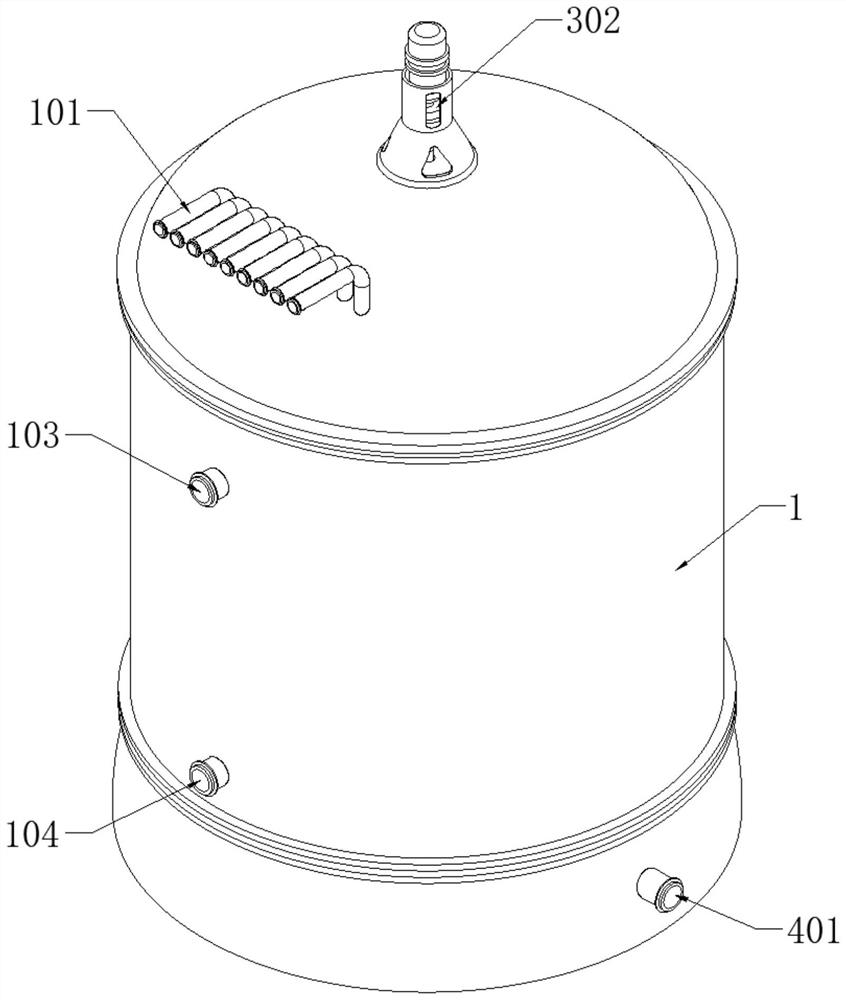

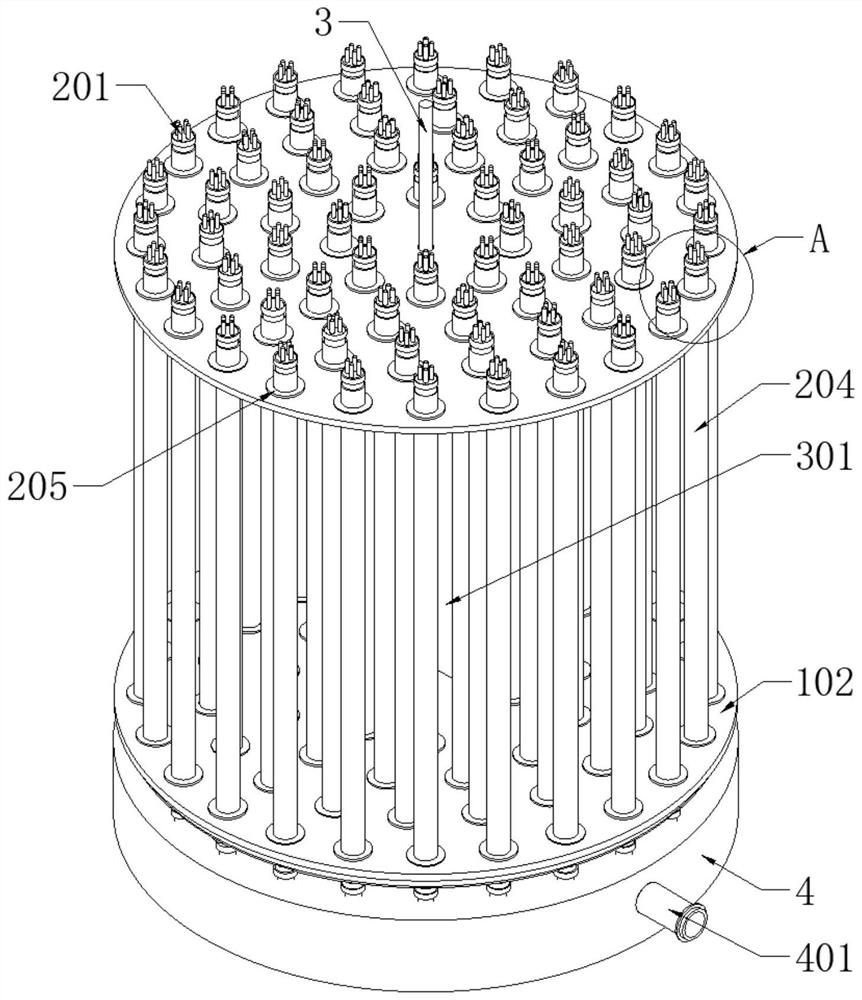

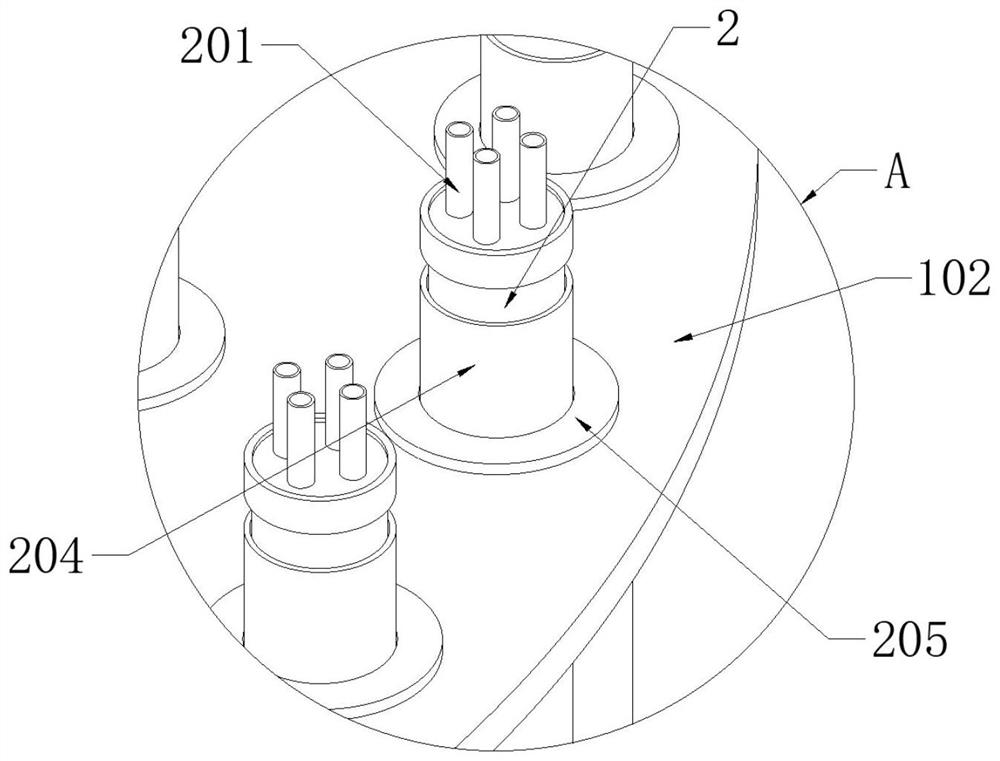

[0056] see Figure 1-10 , a kind of continuous process SAN resin production method based on plug flow reactor, comprises the following steps:

[0057] S1, heat up, continuously add heat medium to the inside of the reactor body 1 through the heat medium inlet 103 fixedly installed on the outer end wall of the reactor body 1, and pass through the heat medium outlet 104 pairs fixedly installed on the outer end wall of the reactor body 1 The heat medium injected inside the reactor body 1 is withdrawn, and heat medium circulation heating is formed inside the reactor body 1 to improve the ambient temperature of a plurality of reaction tubes 2 inside the reactor body 1;

[0058] S2, feeding, through multiple main feeding pipes 101 provided on the reactor body 1, styrene and acrylonitrile are added into the polymerization reactor according to the ratio of 3:1, and the molecular weight modifier is added into the polymerization reactor according to the ratio of 1000ppm;

[0059] S3, ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com