Multi-frequency wave-absorbing patch for offshore wind power project and preparation method of multi-frequency wave-absorbing patch

A wave-absorbing patch and offshore wind power technology, applied in the field of wave-absorbing materials, can solve the problems that the service life of wave-absorbing materials cannot meet the requirements, affect the combat performance of military systems, harsh climate and environmental conditions, etc., and achieve good harsh climate tolerance. The effect of sexual performance, maintaining appearance consistency, and good appearance performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

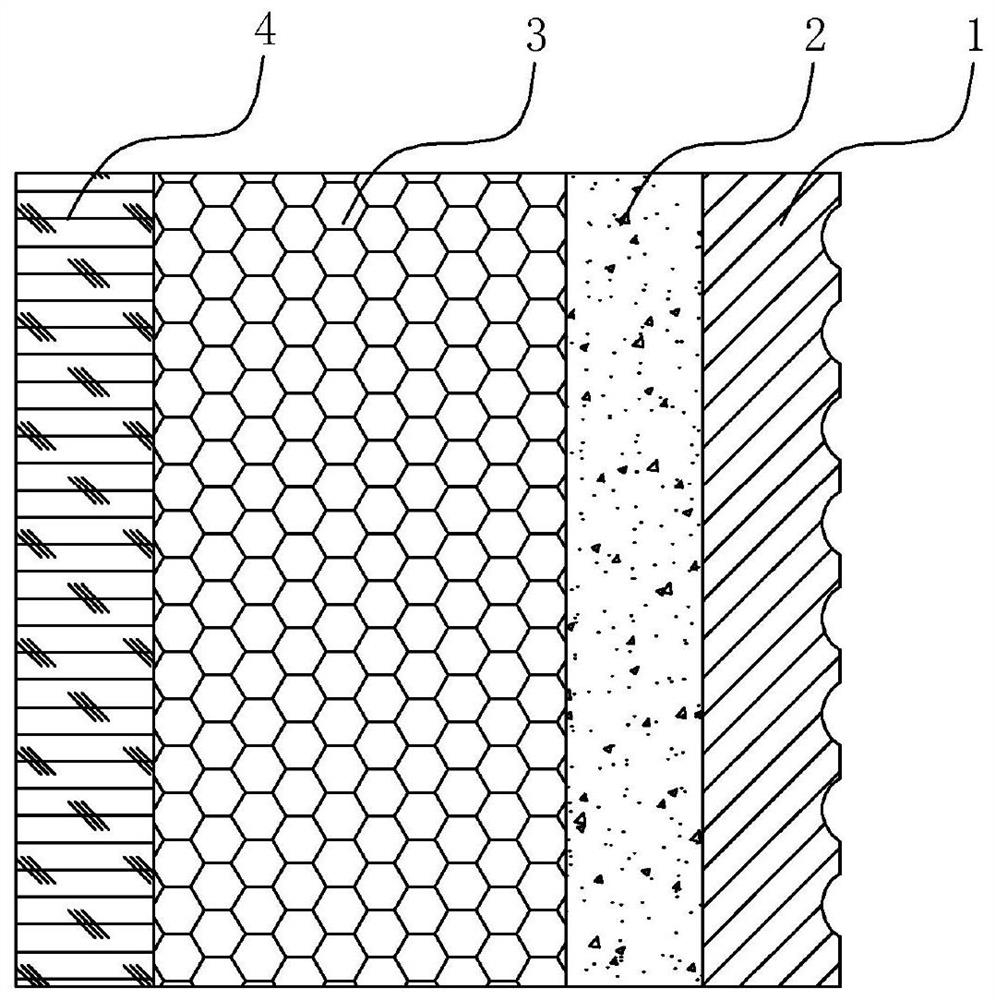

[0053] Weigh 160 parts of flaky hydroxyl iron powder with a particle size of 3-5 microns and 50 parts of thermoplastic polyolefin, mix and heat to 160-170°C, heat and stir for 10 minutes to obtain the wave-absorbing layer slurry, and mix the wave-absorbing layer slurry Rolling treatment by a roller press machine to obtain a 1.5mm wave-absorbing layer;

[0054] Weigh 50 parts of flaky hydroxyl iron powder with a particle size of 3-5 microns, 30 parts of thermoplastic polyolefin, 1 part of copper-coated graphite powder with a particle size of 3-5 microns, and nickel-plated carbon fibers with an average length of 0.1-2mm 1 part, mixed and heated to 160-170°C, kept warm and stirred for 10 minutes to obtain a transition layer slurry, and the transition layer slurry was rolled by a roller press to obtain a 0.5mm transition layer;

[0055]Weigh 95 parts of thermoplastic polyolefin, 0.1 part of leveling agent and 0.1 part of defoamer, mix and heat to 160-170°C, keep warm and stir for ...

Embodiment 2

[0059] Weigh 160 parts of flaky hydroxyl iron powder with a particle size of 3-5 microns, 50 parts of thermoplastic polyolefin, 1 part of coupling agent, 1 part of dispersing agent, 3 parts of leveling agent, and 1 part of defoamer, mix and heat To 160-170°C, keep warm and stir for 10 minutes to obtain the wave-absorbing layer slurry, and roll the wave-absorbing layer slurry through a roller press to obtain a 1.5mm wave-absorbing layer;

[0060] Weigh 50 parts of flaky hydroxyl iron powder with a particle size of 3-5 microns, 30 parts of thermoplastic polyolefin, 1 part of copper-coated graphite powder with a particle size of 3-5 microns, and nickel-plated carbon fibers with an average length of 0.1-2mm 1 part, 0.1 part of coupling agent, 0.1 part of dispersant, 0.1 part of leveling agent and 0.1 part of defoamer, mixed and heated to 160-170 ° C, kept stirring for 10 minutes to obtain the transition layer slurry, the transition layer slurry Rolling treatment by a roller press ...

Embodiment 3

[0065] Weigh 165 parts of flaky hydroxyl iron powder with a particle size of 3-5 microns, 55 parts of thermoplastic polyolefin, 1.5 parts of coupling agent, 1.5 parts of dispersing agent, 4 parts of leveling agent, and 2 parts of defoamer, mix and heat To 160-170°C, heat preservation and stirring for 15 minutes to obtain the wave-absorbing layer slurry, and roll the wave-absorbing layer slurry through a roller press to obtain a 1mm wave-absorbing layer;

[0066] Weigh 55 parts of flaky hydroxyl iron powder with a particle size of 3-5 microns, 35 parts of thermoplastic polyolefin, 5 parts of copper-coated graphite powder with a particle size of 3-5 microns, and nickel-plated carbon fibers with an average length of 0.1-2mm 5 parts, 1 part of coupling agent, 1 part of dispersant, 1 part of leveling agent and 1 part of defoamer, mixed and heated to 160-170 ° C, kept stirring for 15 minutes to obtain the transition layer slurry, the transition layer slurry Rolling treatment by a ro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com