Nanoscale wear-resistant weather-resistant waterproof adhesive and preparation method thereof

Adhesive, nano-scale technology, applied in adhesives, non-polymer adhesive additives, adhesive additives, etc., can solve problems such as economic loss, affecting the use of objects, loose adhesives, etc., to ensure stability, improve utilization, The effect of reducing the burden

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

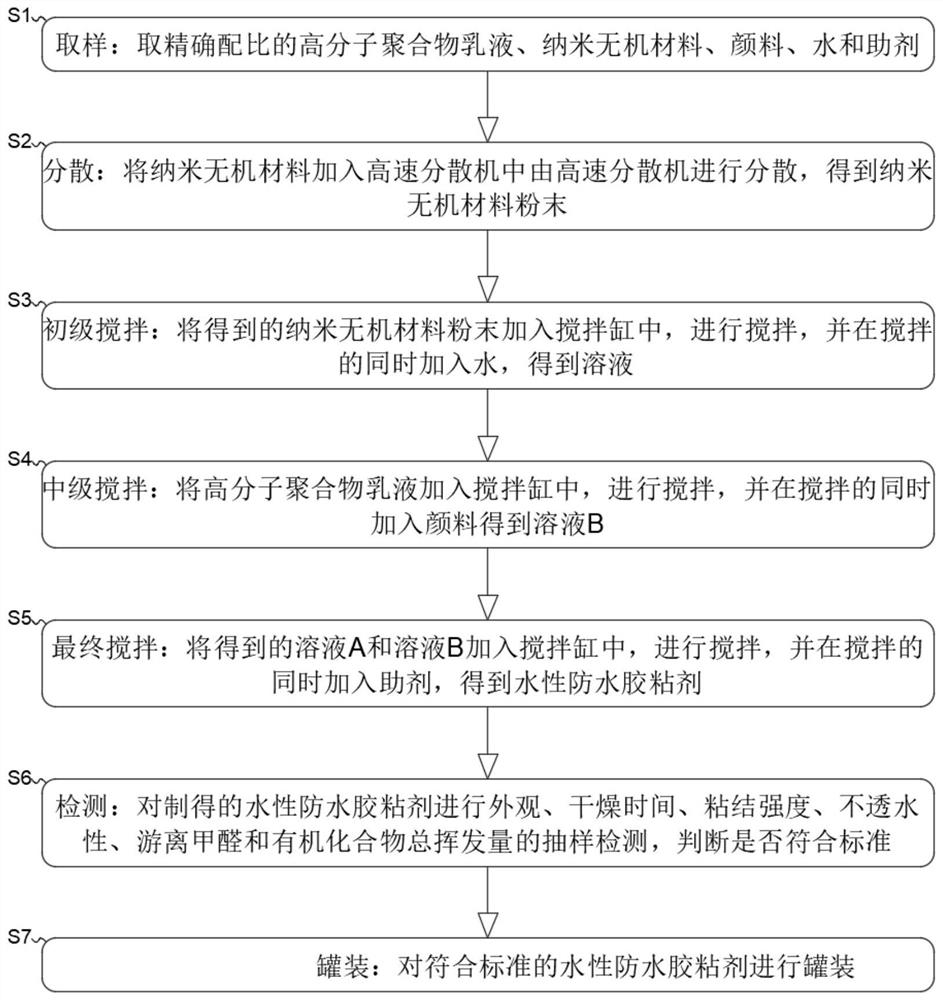

[0040] refer to figure 1 , a nanoscale wear-resistant weather-resistant waterproof adhesive preparation method, the steps are as follows:

[0041] S1: Sampling: Take high molecular polymer emulsion, nano-inorganic materials, pigments, water and additives in precise proportions, and the sampling ratio is:

[0042] 40-45 parts of polymer emulsion; 35-40 parts of nano-inorganic materials; 5-10 parts of pigments; 20-25 parts of water; 1-2 parts of additives;

[0043] S2: Dispersion: adding nano-inorganic materials into a high-speed disperser and dispersing by a high-speed disperser to obtain nano-inorganic material powder, and the dispersion time is 10-40 minutes;

[0044] S3: primary stirring: adding the obtained nano-inorganic material powder into the mixing tank, stirring, and adding water while stirring to obtain solution A, and the stirring time is 30-60 minutes;

[0045] S4: Intermediate stirring: Add the high molecular polymer emulsion into the mixing tank, stir, and add ...

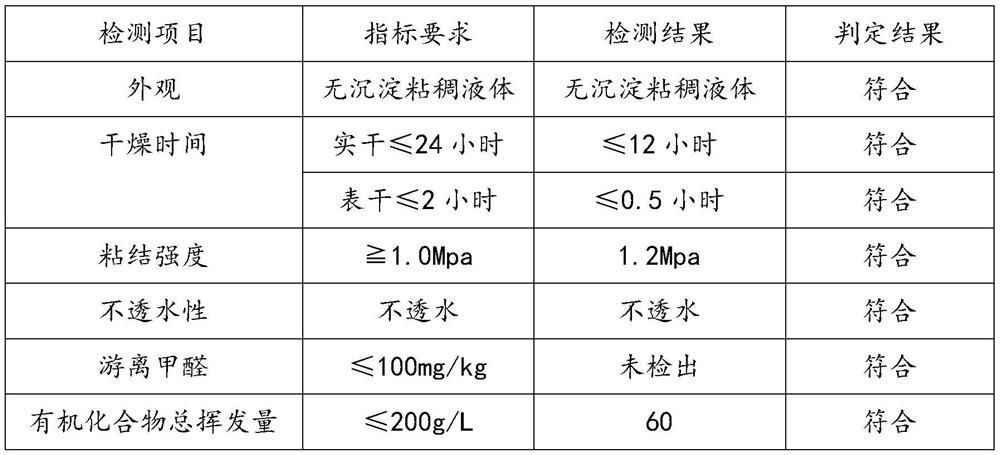

Embodiment 1

[0050] S1: Sampling: Take high molecular polymer emulsion, nano-inorganic materials, pigments, water and additives in precise proportions, and the sampling ratio is:

[0051] 40 parts of polymer emulsion; 35 parts of nano-inorganic material; 5 parts of pigment; 20 parts of water; 1 part of auxiliary agent;

[0052] S2: Dispersion: adding 35 parts of nano-inorganic materials into a high-speed disperser and dispersing by the high-speed disperser to obtain nano-inorganic material powder, and the dispersion time is 10 minutes;

[0053]S3: primary stirring: adding the obtained nano-inorganic material powder into the stirring tank, stirring, and adding 20 parts of water while stirring to obtain solution A, and the stirring time is 30 minutes;

[0054] S4: Intermediate stirring: add 40 parts of high molecular polymer emulsion into the mixing tank, stir, and add 5 parts of pigment to obtain solution B while stirring, and the stirring time is 20 minutes;

[0055] S5: Final stirring: a...

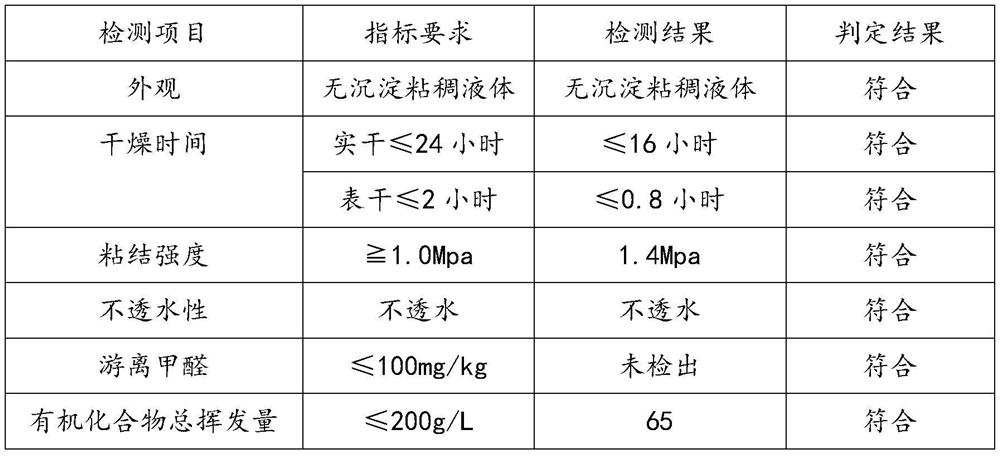

Embodiment 2

[0061] S1: Sampling: Take high molecular polymer emulsion, nano-inorganic materials, pigments, water and additives in precise proportions, and the sampling ratio is:

[0062] 45 parts of polymer emulsion; 35 parts of nano-inorganic material; 10 parts of pigment; 20 parts of water; 2 parts of auxiliary agent;

[0063] S2: Dispersion: adding 35 parts of nano-inorganic materials into a high-speed disperser and dispersing by the high-speed disperser to obtain nano-inorganic material powder, and the dispersion time is 10 minutes;

[0064] S3: primary stirring: adding the obtained nano-inorganic material powder into a stirring tank, stirring, and adding 20 parts of water while stirring to obtain a solution A, and the stirring time is 40 minutes;

[0065] S4: Intermediate stirring: Add 45 parts of high molecular polymer emulsion into the mixing tank, stir, and add 10 parts of pigment to obtain solution B while stirring, and the stirring time is 30 minutes;

[0066] S5: Final stirrin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com