Intermediate shaft assembly, gearbox, vehicle and assembling method of intermediate shaft assembly

A technology for intermediate shafts and gearboxes, applied in the field of gearboxes, which can solve the problems of difficult pin hole punching and pin threading operations, long processing time of intermediate shaft assemblies, and difficult disassembly of transmission gears, etc., to achieve simple assembly and simplified gear alignment tooling , Increase the effect of frictional resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

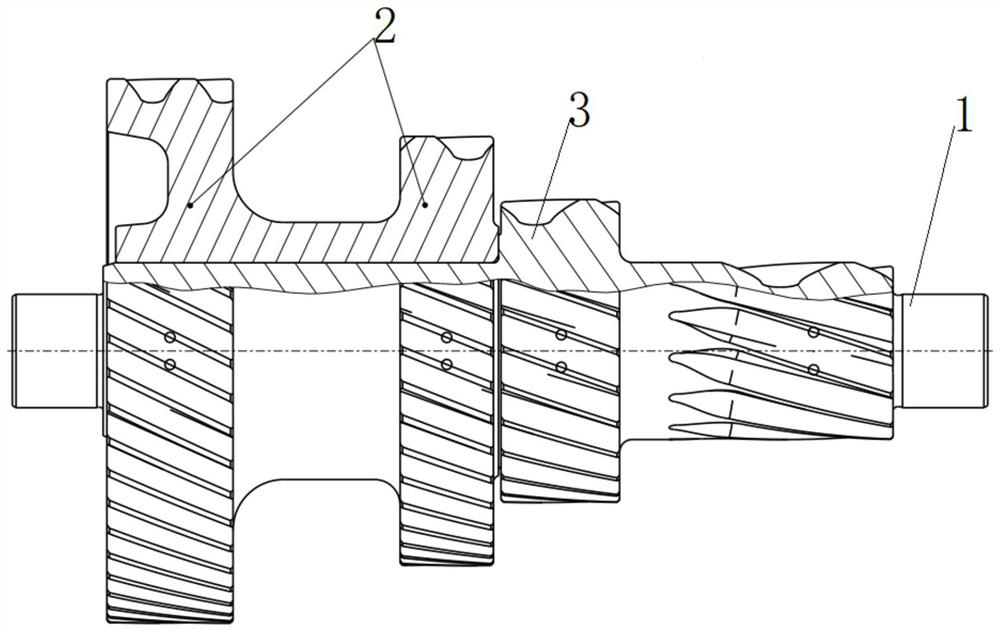

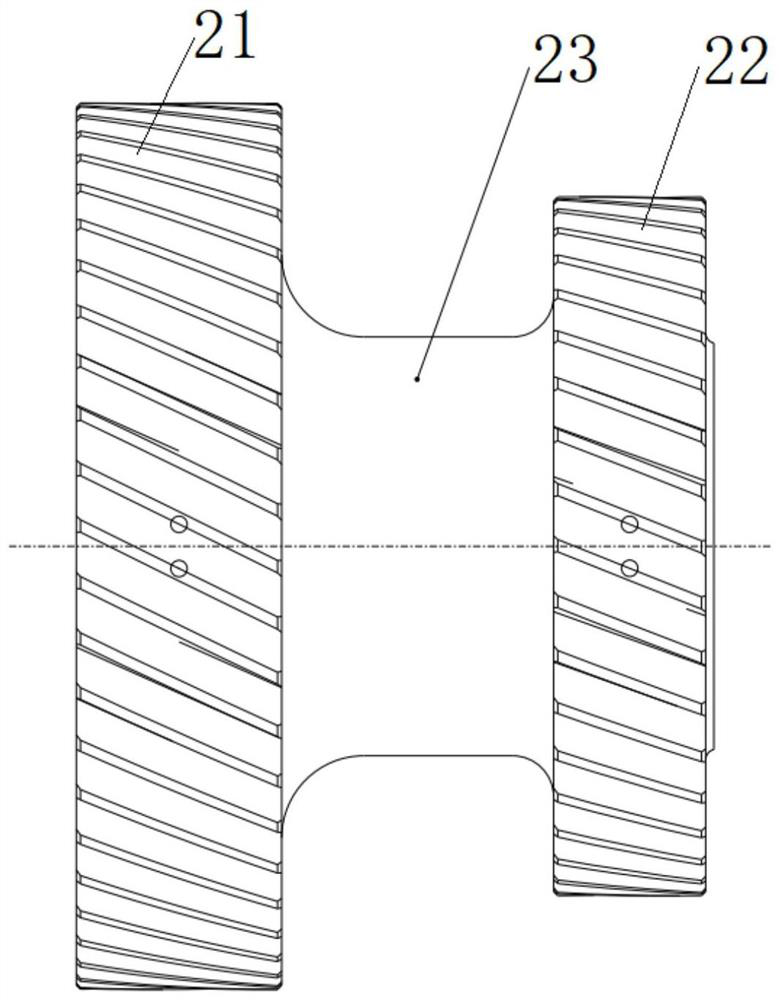

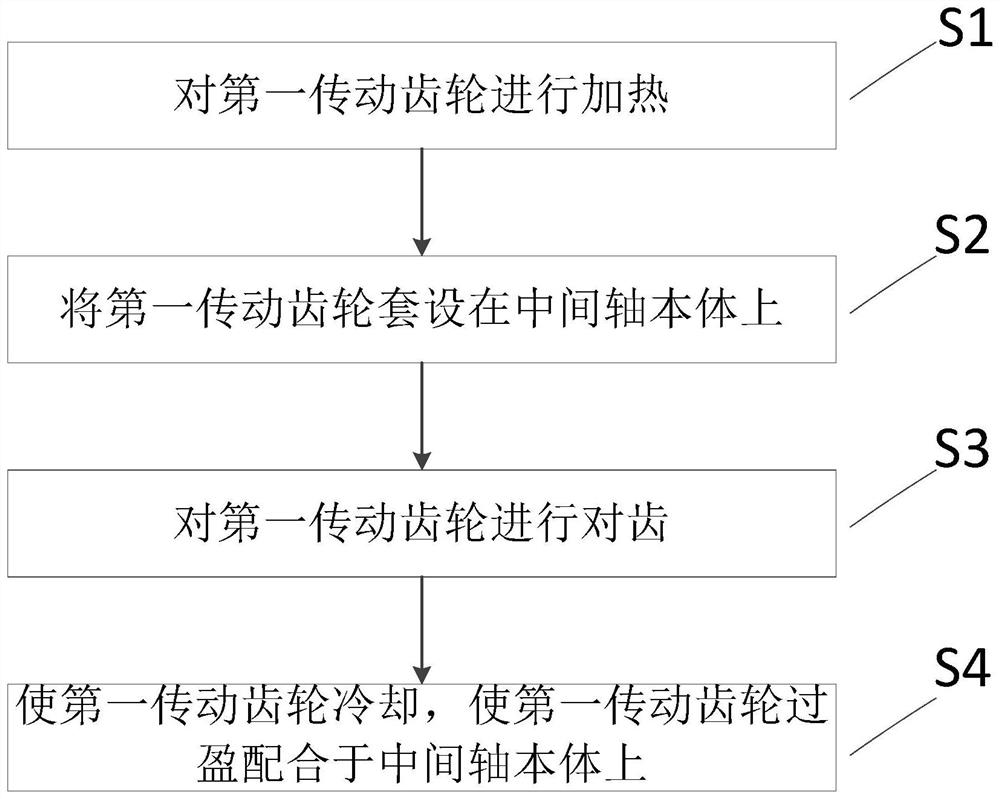

[0035] This embodiment provides an intermediate shaft assembly, such as figure 1 As shown, it includes an intermediate shaft body 1 and at least one first transmission gear 2 . Wherein, the first transmission gear 2 is interference fit on the intermediate shaft body 1; the first transmission gear 2 is a double gear or a multiple gear.

[0036] Because the transmission gears on the intermediate shaft body 1 in the prior art are all single gears, the contact area between the shaft hole of the transmission gear and the intermediate shaft is small, the frictional resistance between the transmission gear and the intermediate shaft is small, and the transmission gear is interference fit on the intermediate shaft Finally, it is easy to slip or rotate on the intermediate shaft. In order to prevent the transmission gear from rotating, the transmission gear needs to be fixed on the intermediate shaft body 1 by pins.

[0037]In the intermediate shaft assembly of this structure, the inte...

Embodiment 2

[0051] This embodiment provides a gearbox, including the intermediate shaft assembly and the housing in Embodiment 1, and the intermediate shaft assembly is arranged on the housing.

[0052] In the gearbox with this structure, the setting of the first transmission gear 2 in it effectively increases the frictional resistance between the first transmission gear 2 and the intermediate shaft body 1, and improves the resistance of the cooperation between the first transmission gear 2 and the intermediate shaft body 1. The torsion coefficient can effectively prevent the first transmission gear 2 from rotating relative to the intermediate shaft body 1, and ensure the alignment accuracy of each gear on the intermediate shaft. The processing and assembly of the intermediate shaft assembly is simple, and the processing efficiency of the intermediate shaft assembly can be effectively improved. After the intermediate shaft assembly is assembled, the first transmission gear 2 can be pressed...

Embodiment 3

[0054] This embodiment provides a vehicle, including the gearbox in Embodiment 2. Vehicles include family cars and engineering work vehicles, etc.

[0055] In the vehicle with this structure, the arrangement of the first transmission gear 2 in it can effectively prevent the first transmission gear 2 from rotating relative to the intermediate shaft body 1, the processing and assembly of the intermediate shaft assembly is simple, and the processing efficiency of the intermediate shaft assembly can be effectively improved. After the intermediate shaft assembly is assembled, the first transmission gear 2 can be pressed out from the intermediate shaft body 1 by a large-tonnage press, so as to realize the disassembly of the first transmission gear 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com