Internal circulation oil way system for intelligently detecting oil supply state of air compressor

A technology of intelligent detection and oil circuit system, which is applied in the direction of mechanical equipment, telemetry/remote control selection device, transmission device parts, etc. It can solve the problems of unsuitable vehicle-mounted chassis installation environment, working oil pressure monitoring and detection, increasing the volume of air compressors, etc. problems, to achieve the effects of reducing the probability of locking, simplifying the manufacturing and molding process, and optimizing the assembly structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

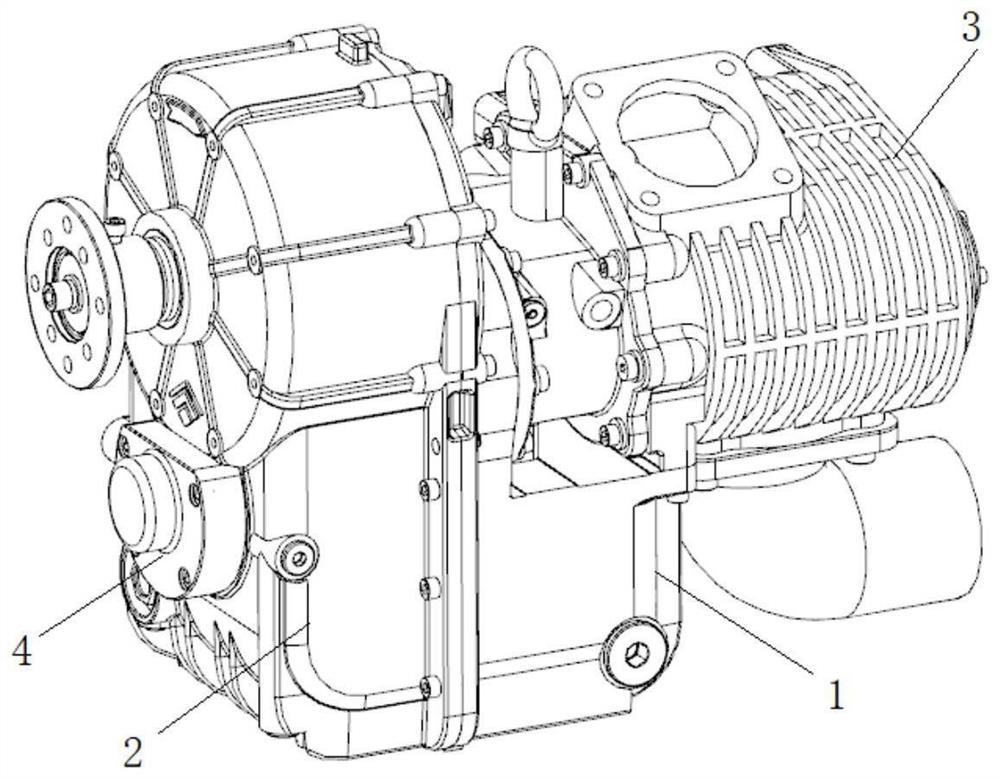

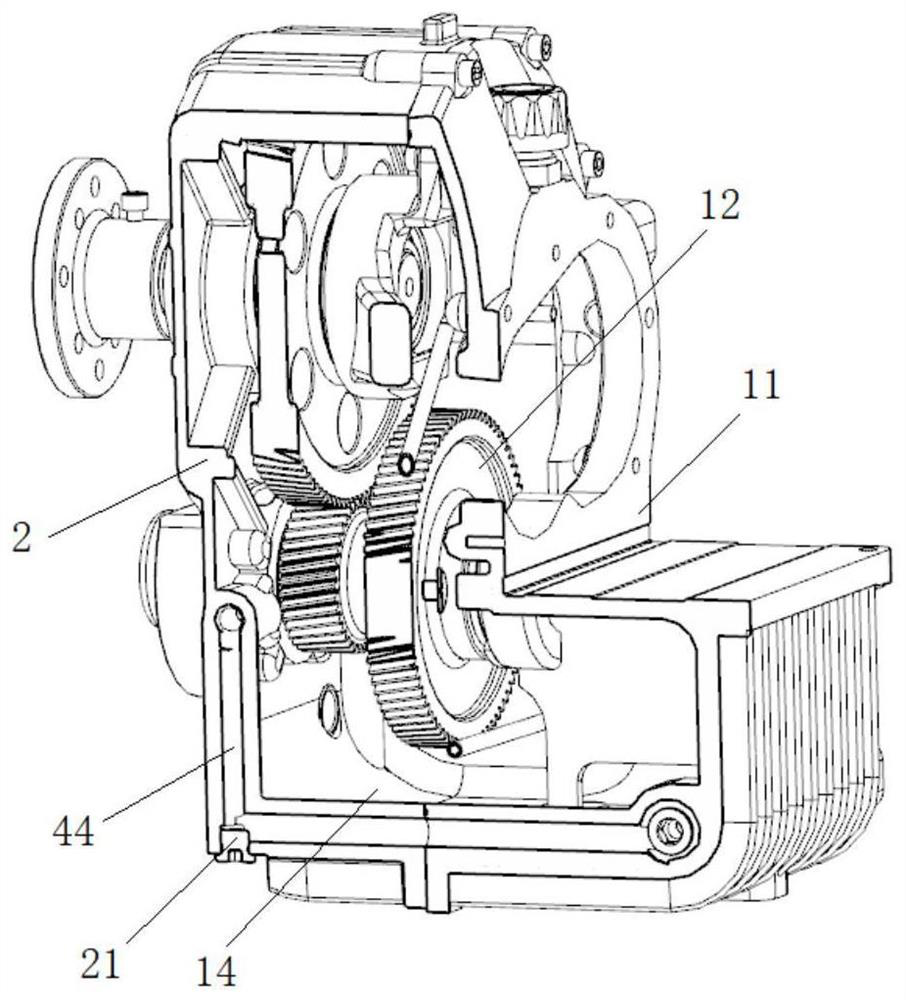

[0032] Refer Figure 1-10 As shown, the present embodiment is the internal circulating oil line system intelligently detecting the air pressure supply state, including the gearbox assembly 1, detachable body cover 2 on the side of the gearbox assembly 1, detachable to the gear The head assembly 3 of the other side of the box assembly is, and the internal circulating oil structure provided between the body cover 2 and the head assembly 3.

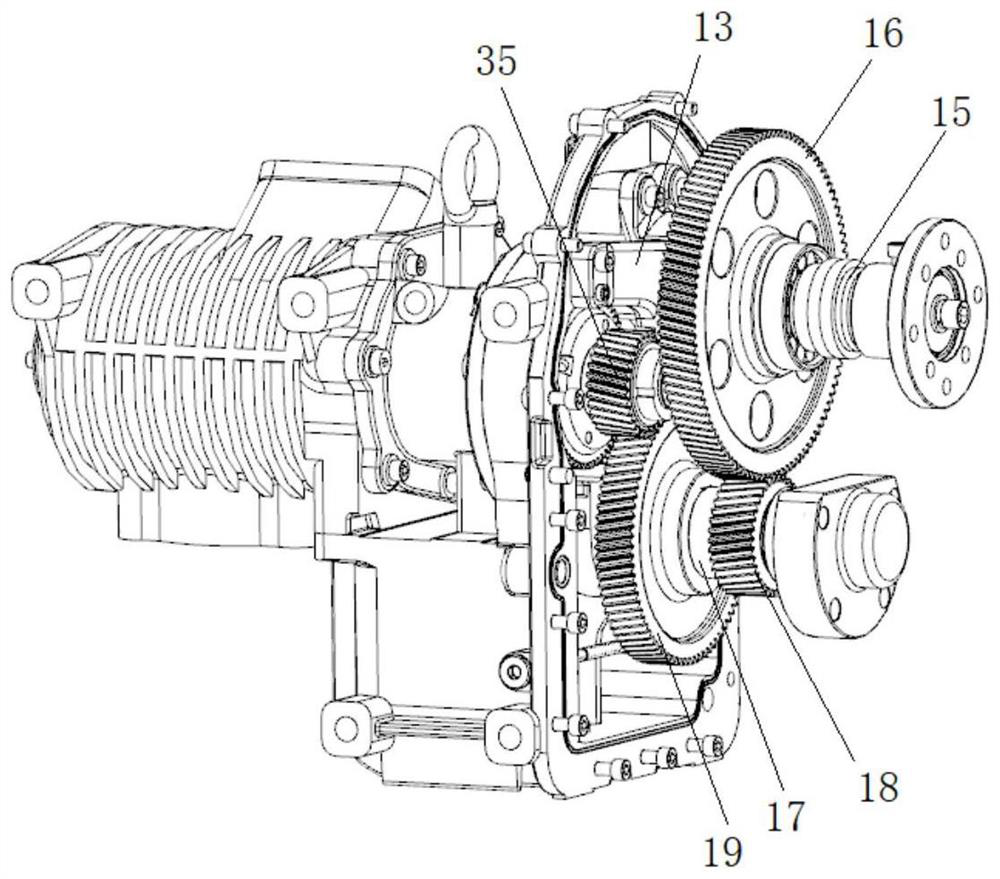

[0033] The gearbox assembly 1 includes a gearbox body 11, mounted in the gearbox 11 and the multi-stage growth rate transmission gear set 12 in the body cover 2. The gear case 11 is an L-shaped structure, and the upper portion of the side wall of the gearbox 11 is mounted, and the gear case 11, and the body cover 2 form an oil chamber 14.

[0034] The multi-stage growth rate transmission gear set 12 includes a first-stage active transmission shaft 15 that connects the bearing housing 13 and through the body cover 2, which is arranged at one stage...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com