MEMS acoustic film surface defect detection method based on frequency domain transformation

A technology of frequency domain transformation and defect detection, which is applied in image data processing, instruments, calculations, etc., can solve the problems of large calculation of filter parameters and unsatisfactory rapid detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other.

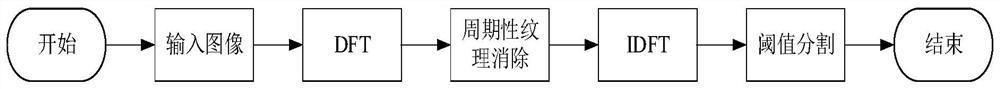

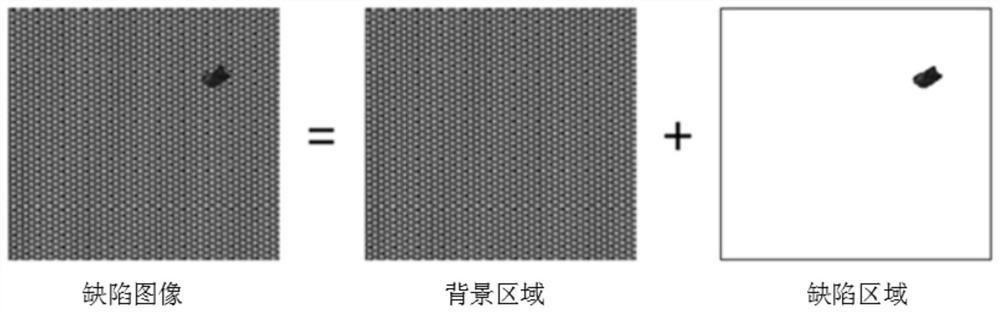

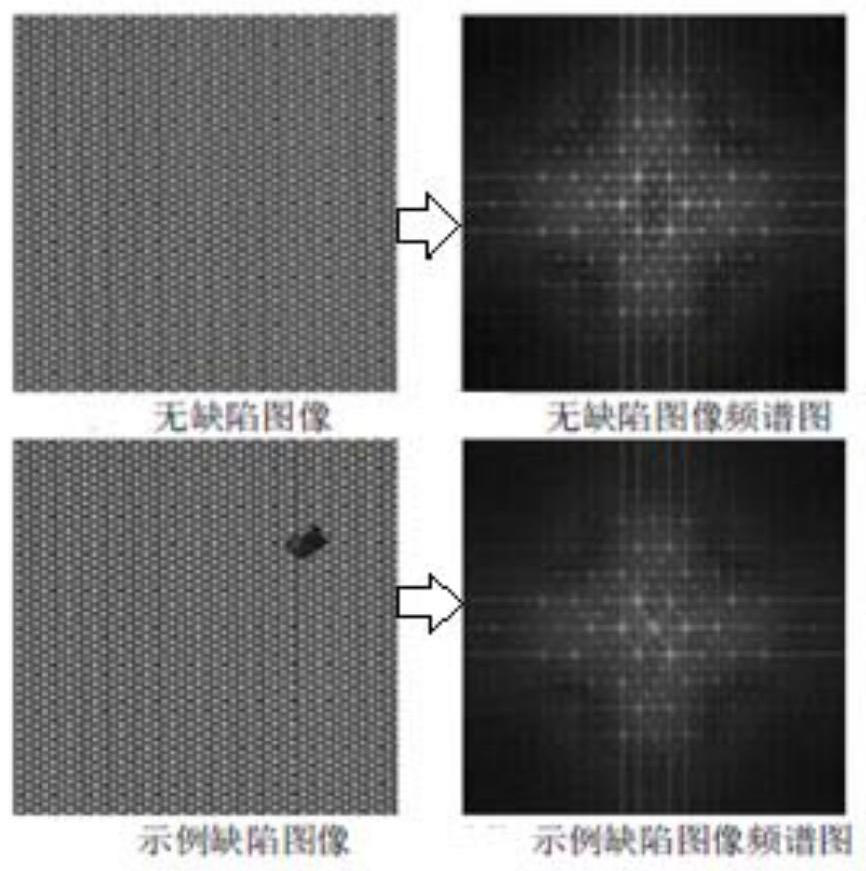

[0052] As a multi-field cross-comprehensive technology involving optics, computer technology and image processing, machine vision inspection technology has important research significance for improving the manufacturing level of MEMS micro components and reducing production costs due to its advantages of non-contact and high precision. At the same time, because the background texture distribution of the MEMS acoustic film has a certain periodicity, its Fourier spectrum has discreteness and regularity, and the texture characteristics of the background can be extracted through the relevant frequency distribution criteria to eliminate the periodicity in the background Structural texture, so the present invention is based on machine vision detection technology, detects the common defect types (plaque, band and ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com