Supercritical pearl bleaching method and device

A supercritical and supercritical extraction technology, which is applied in the field of craft jewelry, can solve the problems of clear and clean, residual pigment, and inability to extract pearl pigment, so as to improve the dissolution rate, improve work efficiency, and shorten the processing cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

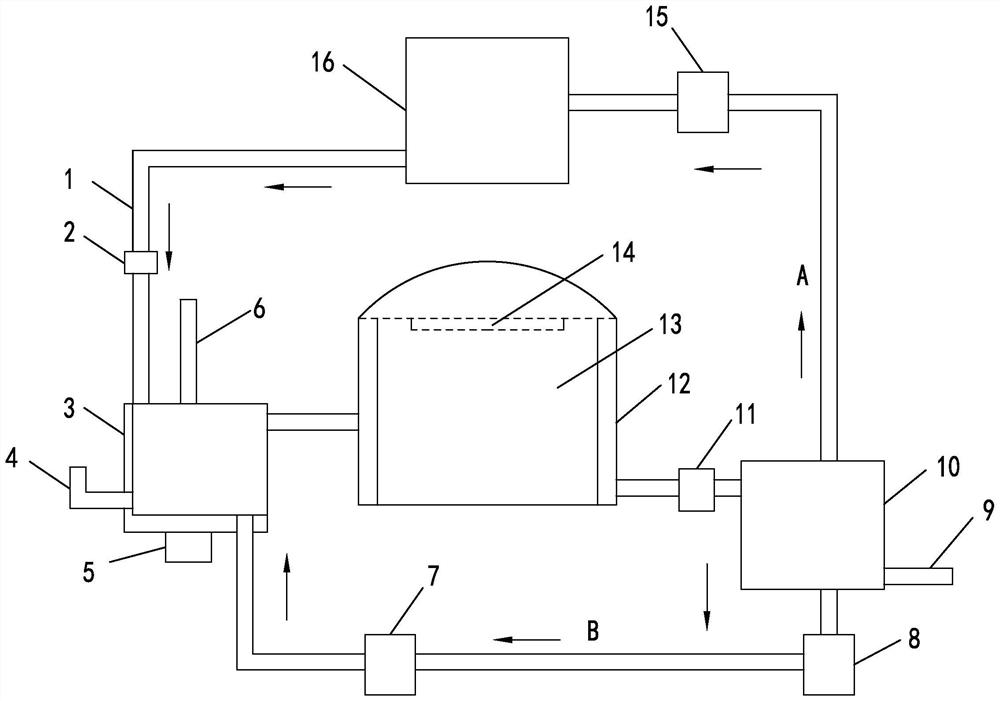

[0039] The supercritical pearl bleaching device of the present invention comprises a carbon dioxide gas circulation loop A and a liquid circulation loop B, and the carbon dioxide gas circulation loop A is composed of a supercritical extraction tank 13, a pressure reducing valve 11, an evaporation separator 10, a booster pump 15, a carbon dioxide storage The tank 16 and the mixer 3 are connected by pipelines, and the liquid circulation circuit B is formed by connecting the supercritical extraction tank 13, the pressure reducing valve 11, the evaporation separator 10, the filter 8, the circulation pump 7 and the mixer 3 by pipelines.

[0040] The mixer 3 is respectively provided with a carbon dioxide fluid injection port, an ethanol injection port and a hydrogen peroxide injection port, and the carbon dioxide fluid injection port is connected to the carbon dioxide storage tank 16 through a carbon dioxide fluid pipe 1, and a valve 2 is arranged on the carbon dioxide fluid pipe 1, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com