Plate-and-frame filter press convenient for discharging and control method

A plate-and-frame filter press and plate-and-frame filter press technology are applied in separation methods, chemical instruments and methods, filtration and separation, etc., which can solve the problems of low degree of automation, cumbersome operation, large labor force, etc., and achieve small unloading space, The effect of facilitating miniaturization and improving the efficiency of unloading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

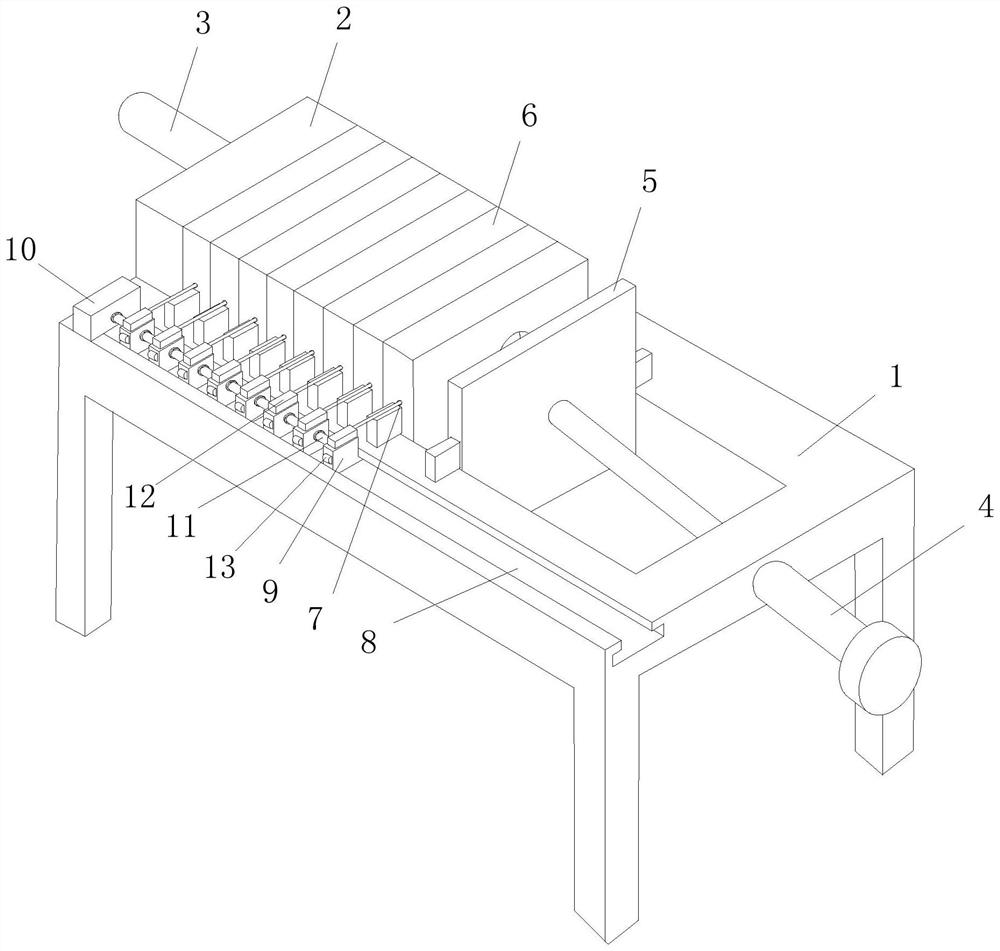

[0034] Such as figure 1 As shown, this embodiment provides a plate and frame filter press that is convenient for unloading, including a frame 1, one end of the frame 1 is provided with a fixing plate 2, and the fixing plate 2 is provided with a liquid inlet pipe 3 , the other end of the frame 1 is provided with a driving mechanism 4, the driving mechanism 4 is connected with an extruding plate 5, the extruding plate 5 is slidingly connected with the frame 1, and the fixed plate 2 and the extruding plate 5 There are several plate and frame filter press plates 6 slidingly connected with the frame 1, at least one side of the plate and frame filter press 6 is provided with a groove 7, and at least one side of the frame 1 is along the length direction A chute 8 is provided, and the sliding block 9 having the same number as the plate and frame filter plate 6 is slidably connected in the chute 8. The frame 1 is provided with a supporting plate 10, and the , the slider 9 and the supp...

Embodiment 2

[0038] On the basis of Embodiment 1, the direction of the telescopic end of the first electric telescopic rod 11 is all towards the extruding plate 5 .

[0039] In this embodiment, in order to facilitate the layout and control of the first electric telescopic rod 11 , the telescopic ends of the first electric telescopic rod are all directed towards the extruding plate 5 .

Embodiment 3

[0041] On the basis of Embodiment 1, grooves 7 are provided on both sides of the plate-and-frame filter press plate 6 , and slide grooves 8 are provided on both sides of the frame 1 .

[0042] In this embodiment, grooves 7 are provided on both sides of the plate and frame filter press plate 6, and slide grooves 8 are arranged on both sides of the frame 1, so that the telescopic end of the second electric telescopic rod 12 can be easily inserted into the corresponding The groove 7 is connected with both sides of the frame filter plate 6, so as to ensure that the frame filter plate 6 can be stably driven to slide along the frame 1 when the first electric telescopic rod 11 is stretched or shortened.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com