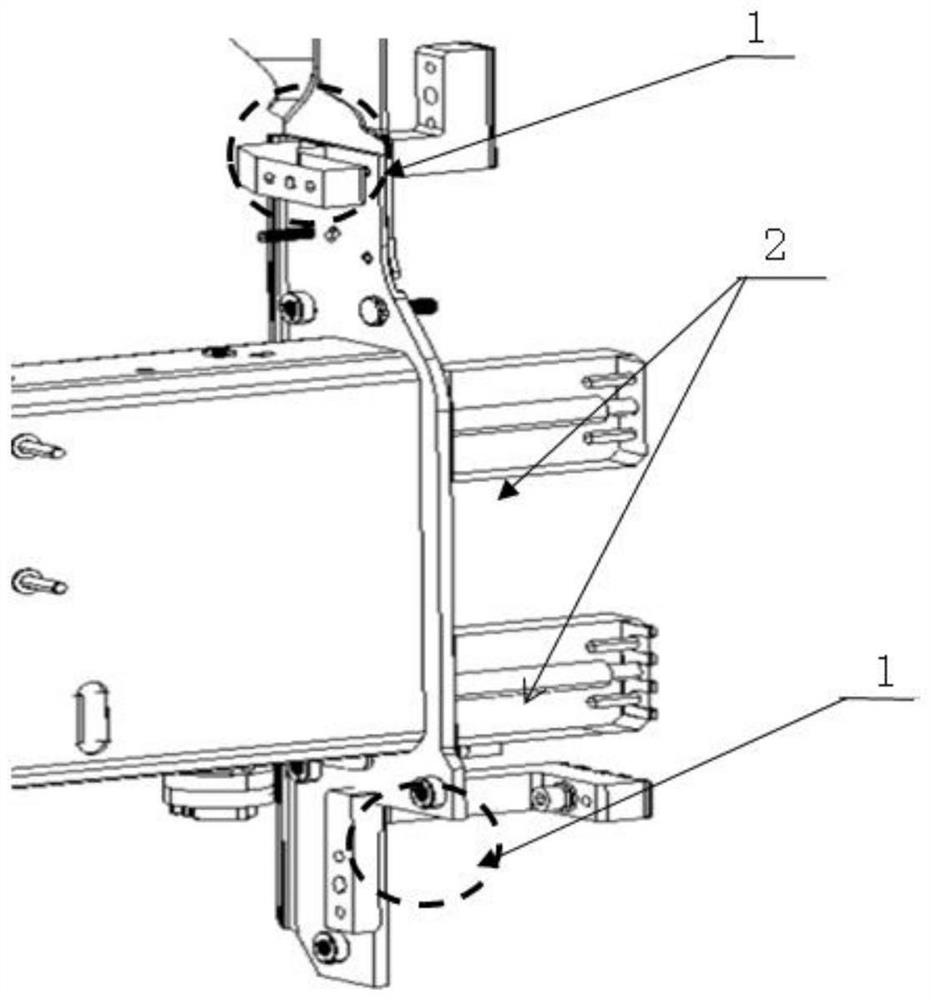

Arc welding deformation preventing mechanism

A deformation mechanism and arc prevention technology, applied in welding equipment, welding accessories, auxiliary welding equipment, etc., can solve the problems of large welding deformation, large arc welding heat input, assembly difficulty, etc., to reduce welding deformation and reduce welding heat. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The technical solution of the present invention is described in detail below through the examples, and the following examples are only exemplary and can only be used to explain and illustrate the technical solution of the present invention, rather than being interpreted as a limitation to the technical solution of the present invention.

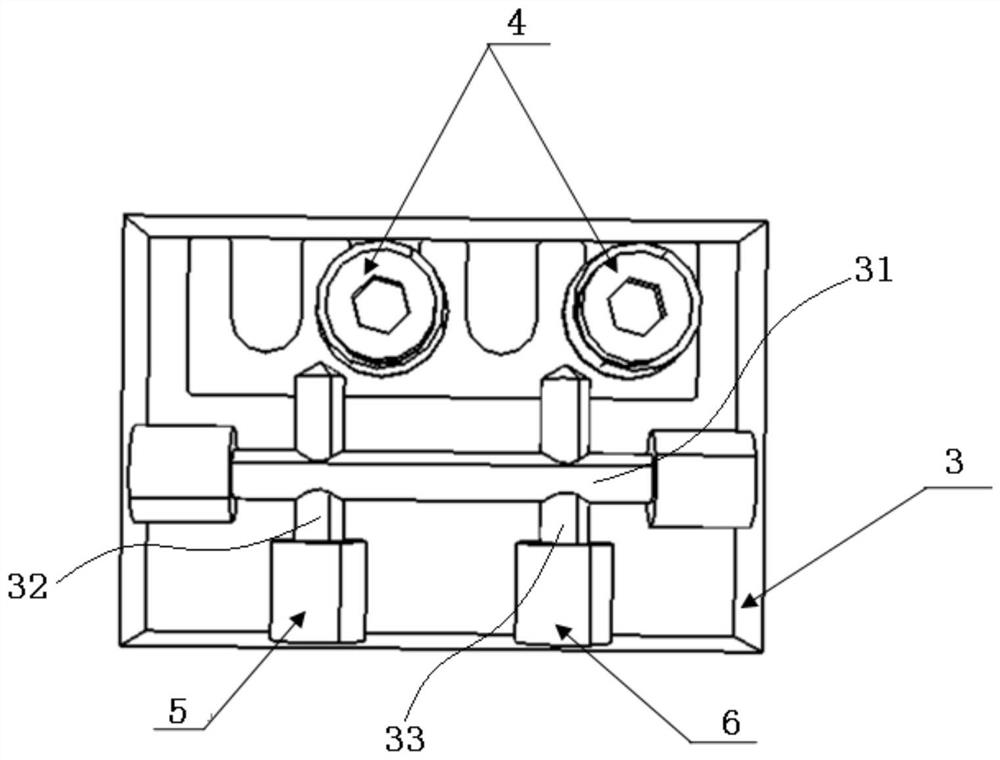

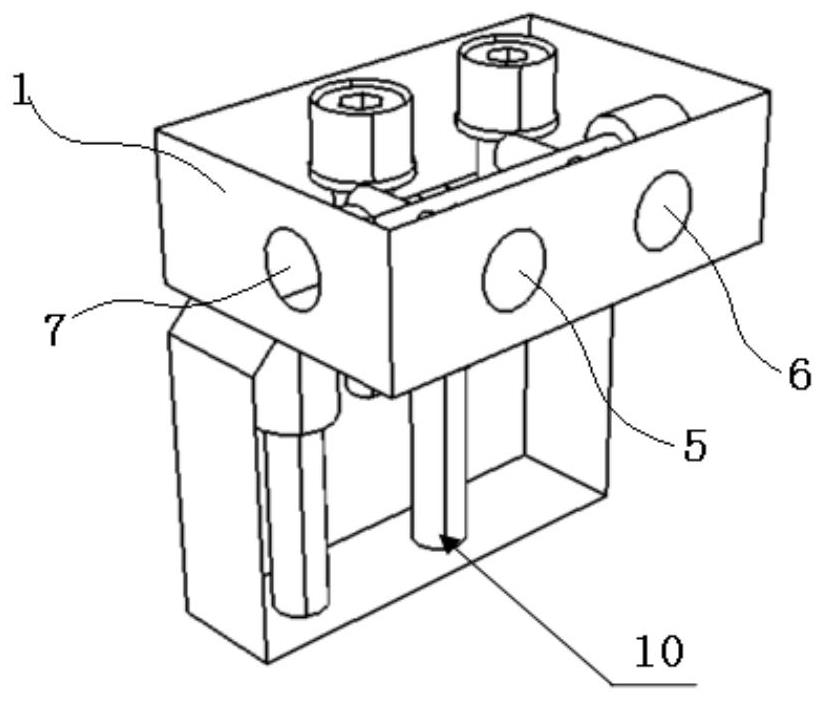

[0027] Such as figure 2 As mentioned above, the arc-proof welding deformation mechanism of the present application includes a heat conduction block 3. In the technical solution of the present application, the heat conduction block is made of copper material. Generally speaking, the heat conduction block of the present application is a rectangular parallelepiped structure. There are mounting holes 4 penetrating up and down, and a circulating waterway is arranged in the heat conducting block. The circulating waterway is provided with a first water inlet 5 and a first water outlet 6 on the side surface of the heat conducting block, respec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com