Welding method of pure niobium cryogenic vacuum pressure vessel

A low-temperature vacuum and pressure vessel technology, which is applied in household containers, welding equipment, electron beam welding equipment, etc., can solve the adverse effects of pure niobium thin-walled pressure vessel welded joints on the mechanical properties of products, electrical conductivity, molding accuracy, out-of-tolerance pressure vessels, Unsatisfactory problems, to achieve the effect of improving welding quality, reducing local deformation, and enhancing electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

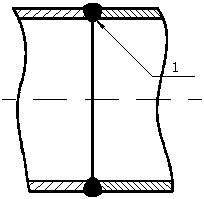

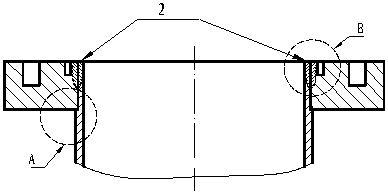

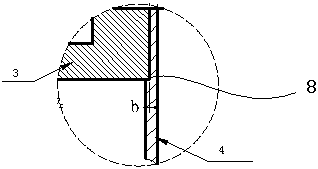

[0020] The welding method of pure niobium low temperature vacuum pressure vessel of the present invention:

[0021] (1) Using vacuum electron beam welding technology

[0022] With the help of the vacuum chamber of the vacuum electron beam welding machine, a relative vacuum environment can be provided for the welding of pure niobium thin-walled pressure vessel components after being vacuumed by mechanical pumps, Roots pumps and diffusion pumps, which is different from the current conventional argon arc welding. Compared with the argon flow (Ar) protection in the air environment used in the method, it can effectively isolate oxygen (O), hydrogen (H), nitrogen (N) and other elements in the air from affecting the high-temperature molten metal and the welding heat-affected zone. Corrosion, while also avoiding the dissolution of argon (Ar) into the welding pool, the metal purity of pure niobium components will not be reduced due to the welding process, so the protection effect achie...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com