Hybrid power four-gear transmission, hybrid power driving system and hybrid power vehicle

A hybrid power and drive system technology, which is applied to the arrangement of multiple different prime movers, power plants, vehicle components, etc. of general power plants, can solve problems such as increasing system complexity, and achieve the effect of simplified structure and good power performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

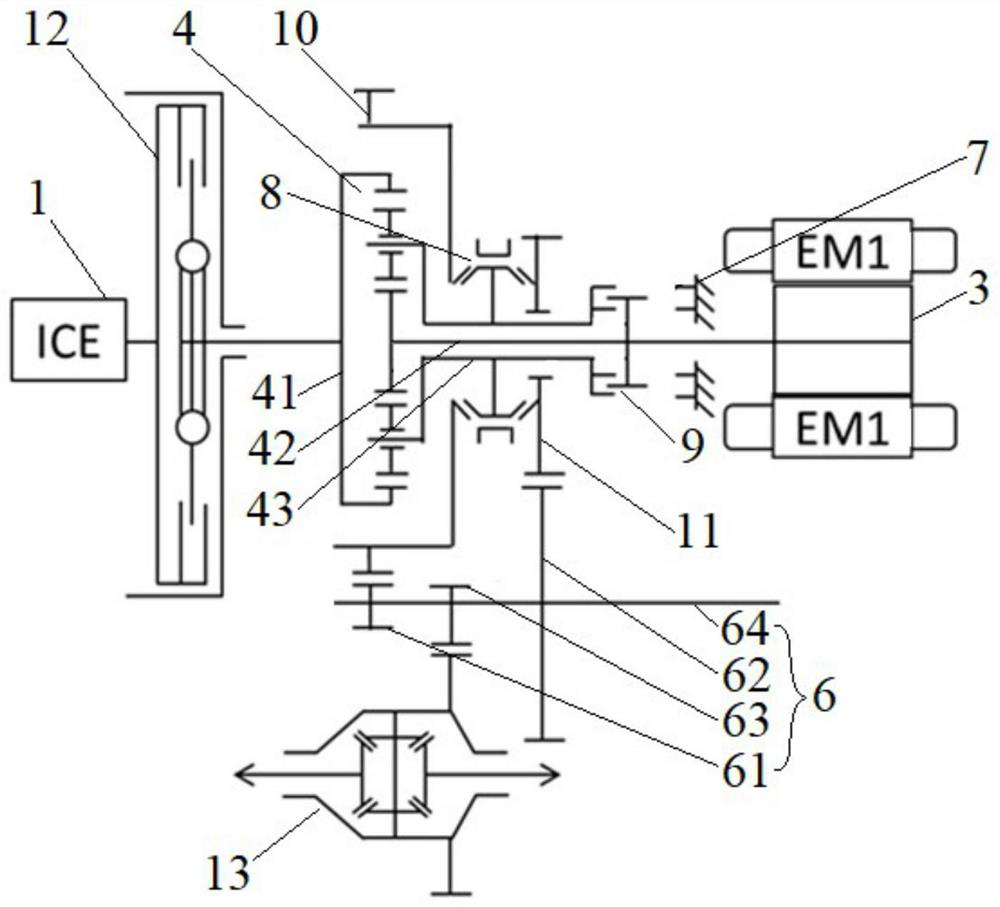

Embodiment 1

[0037] see figure 1 , In this embodiment, a hybrid drive system as a whole includes three components of an engine 1 , a first motor 2 and a hybrid four-speed transmission. The hybrid four-speed transmission has two outstretched shafts, which are respectively used to connect the engine 1 and the first electric machine 2 . The hybrid four-speed transmission has a final reduction gear 63 that keeps meshing with the input gear of the differential 13 for torque transmission. This embodiment does not improve the structure of the engine 1 and the first motor 2, so the specific structure of the engine 1 and the first motor 2, and the connection form of the engine 1 and the first motor 2 with the transmission input and output shaft 64 can refer to the prior art Relevant disclosures, which will not be explained here.

[0038] In some embodiments, a torsion-limiting shock absorber 12 is provided on the rotating shaft of the engine 1, and the torsion-limiting shock absorber uses disc sp...

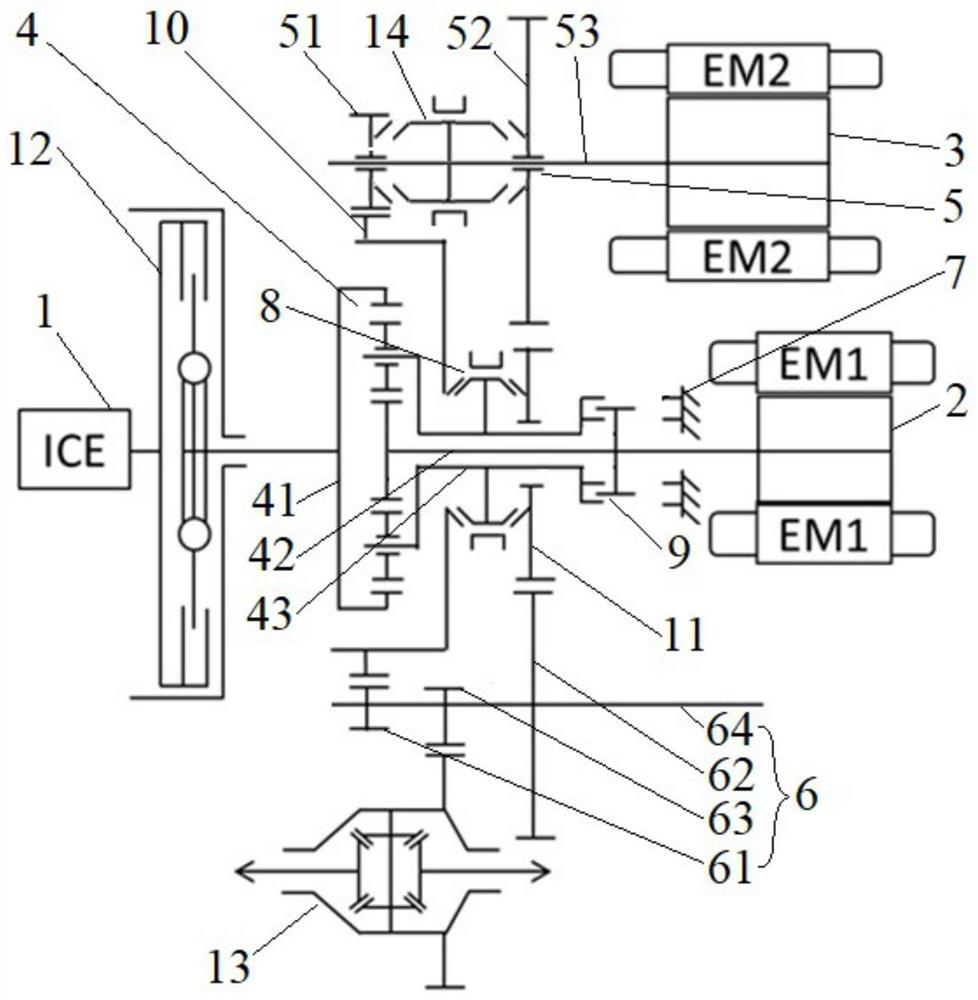

Embodiment 2

[0077] Based on the same inventive concept, a hybrid drive system of this embodiment, see figure 2 , including engine 1, first motor 2, second motor 3 and four components of hybrid four-speed transmission as a whole. The hybrid four-speed transmission has three outstretched shafts, which are respectively used to connect the engine 1 , the first motor 2 and the second motor 3 . The hybrid four-speed transmission has a final reduction gear 63 that keeps meshing with the input gear of the differential 13 for torque transmission. The present embodiment does not improve the structure of the engine 1, the first motor 2 and the second motor 3, so the specific structure of the engine 1, the first motor 2 and the second motor 3, and the engine 1, the first motor 2 and the second motor 3 For the connection form with the input and output shaft 64 of the transmission, reference may be made to related publications in the prior art, and no further description will be made here.

[0078] ...

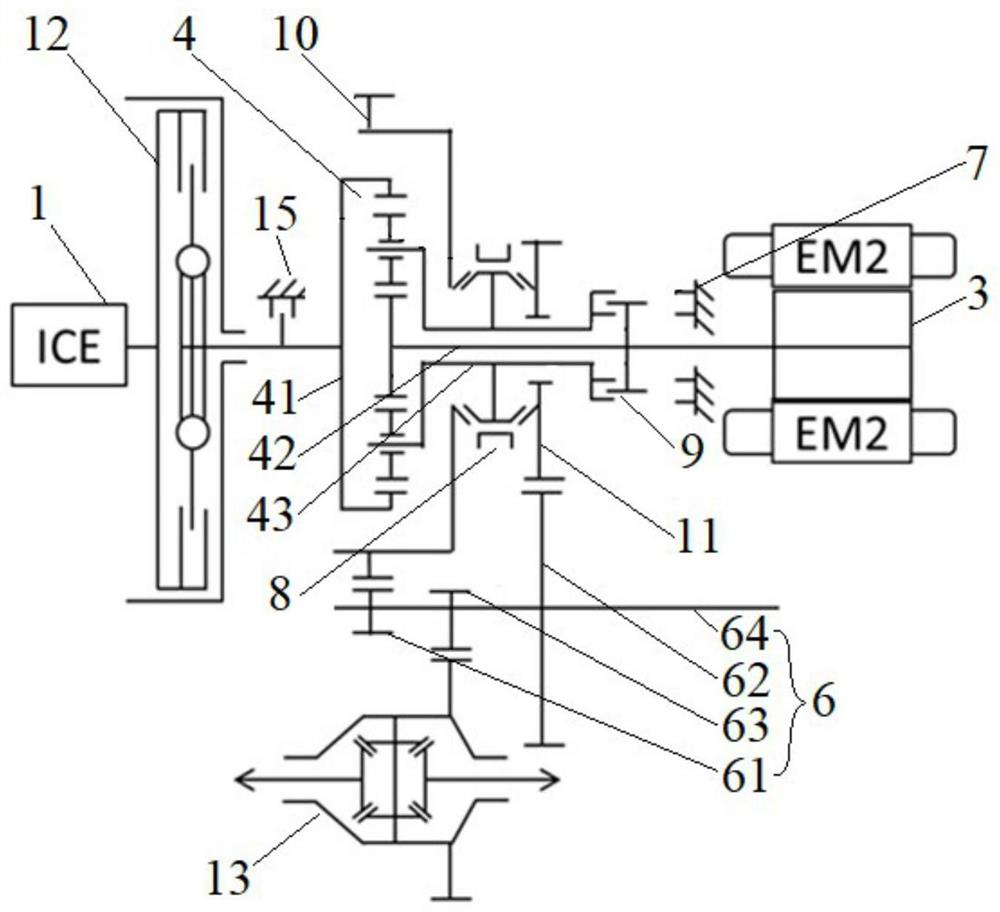

Embodiment 3

[0105] Based on the same inventive concept, a hybrid drive system of this embodiment, see image 3 , including three components of the engine 1, the first motor 2 and the hybrid four-speed transmission as a whole. The hybrid four-speed transmission has two outstretched shafts, which are respectively used to connect the engine 1 and the first electric machine 2 . The hybrid four-speed transmission has a final reduction gear 63 that keeps meshing with the input gear of the differential 13 for torque transmission. This embodiment does not improve the structure of the engine 1 and the first motor 2, so the specific structure of the engine 1 and the first motor 2, and the connection form of the engine 1 and the first motor 2 with the transmission input and output shaft 64 can refer to the prior art Relevant disclosures, which will not be explained here.

[0106] In the hybrid drive system of this embodiment, the hybrid four-speed transmission includes all the technical features o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com