Preparation method of liquid fertilizer

A technology of liquid fertilizer and fermentation liquid, applied in liquid fertilizer, organic fertilizer, inorganic fertilizer and other directions, to achieve the effect of enhancing photosynthesis, improving quality and reducing diseases

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

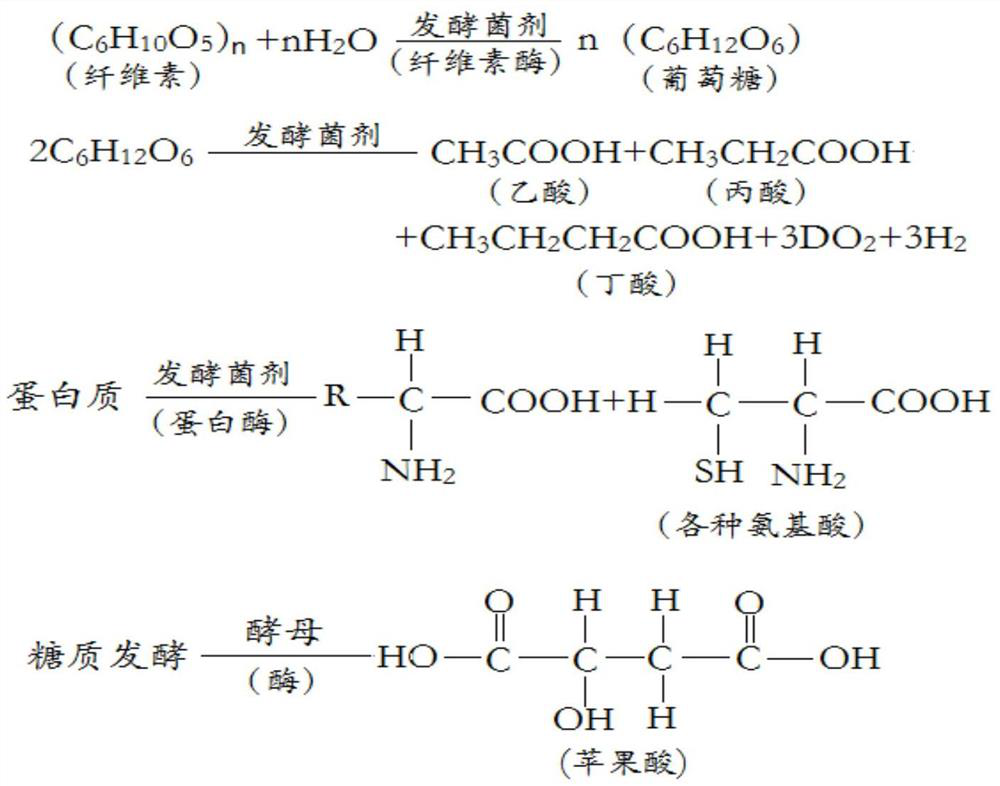

Method used

Image

Examples

Embodiment 1

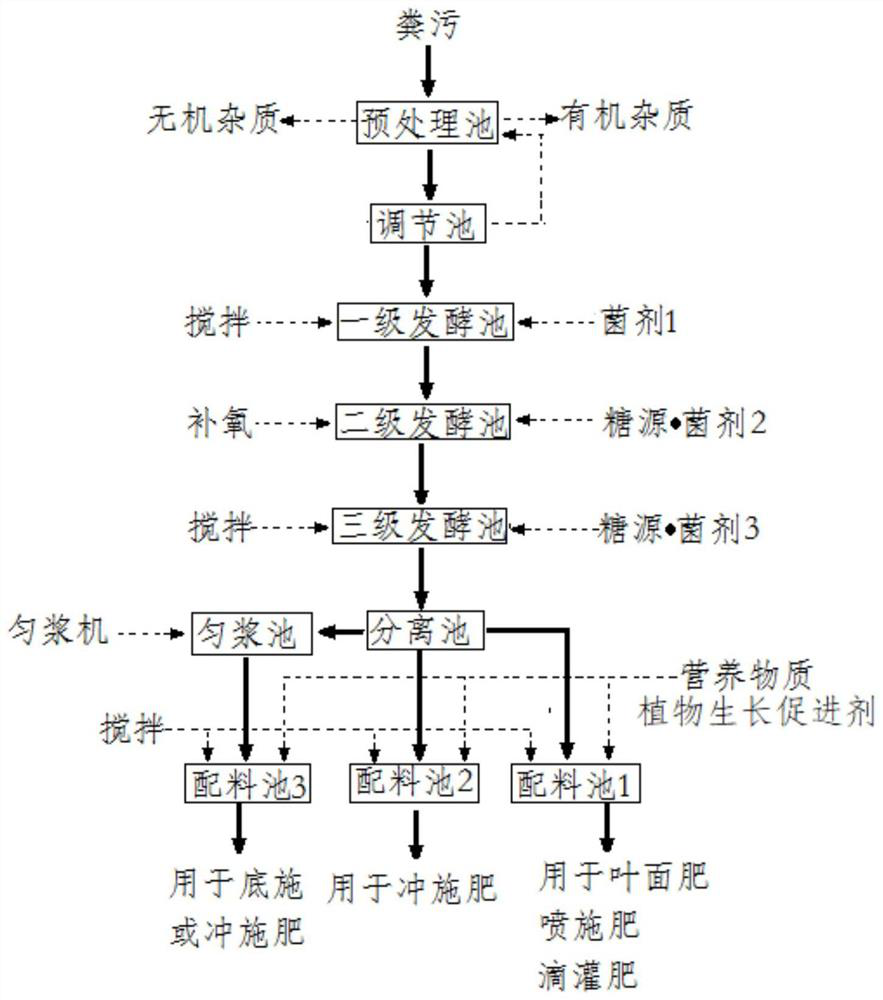

[0059] Such as figure 1 Shown, the liquid fertilizer preparation method provided by the invention comprises the following steps:

[0060] S1, pretreatment: The organic waste liquid used in the present invention is the mixture of rural toilet excrement and pig farm excrement, the waste liquid first enters the pretreatment pool, the pretreatment pool is provided with a stirring device, and the bottom of the pool is provided with a sand collection pit, The sand-settling collection pit is equipped with a sand-settling hoist, and the waste liquid is statically settled after being stirred. Inorganic impurities such as bricks, sand, metal, glass, etc. are deposited in the sand-settling collection pit at the bottom of the pool, and are removed by the sand-settling elevator. A fine grill is installed at the outlet of the pretreatment pool to remove floating and suspended organic impurities.

[0061] The mass fraction of insoluble substances in the effluent of the pretreatment tank is ...

Embodiment 2

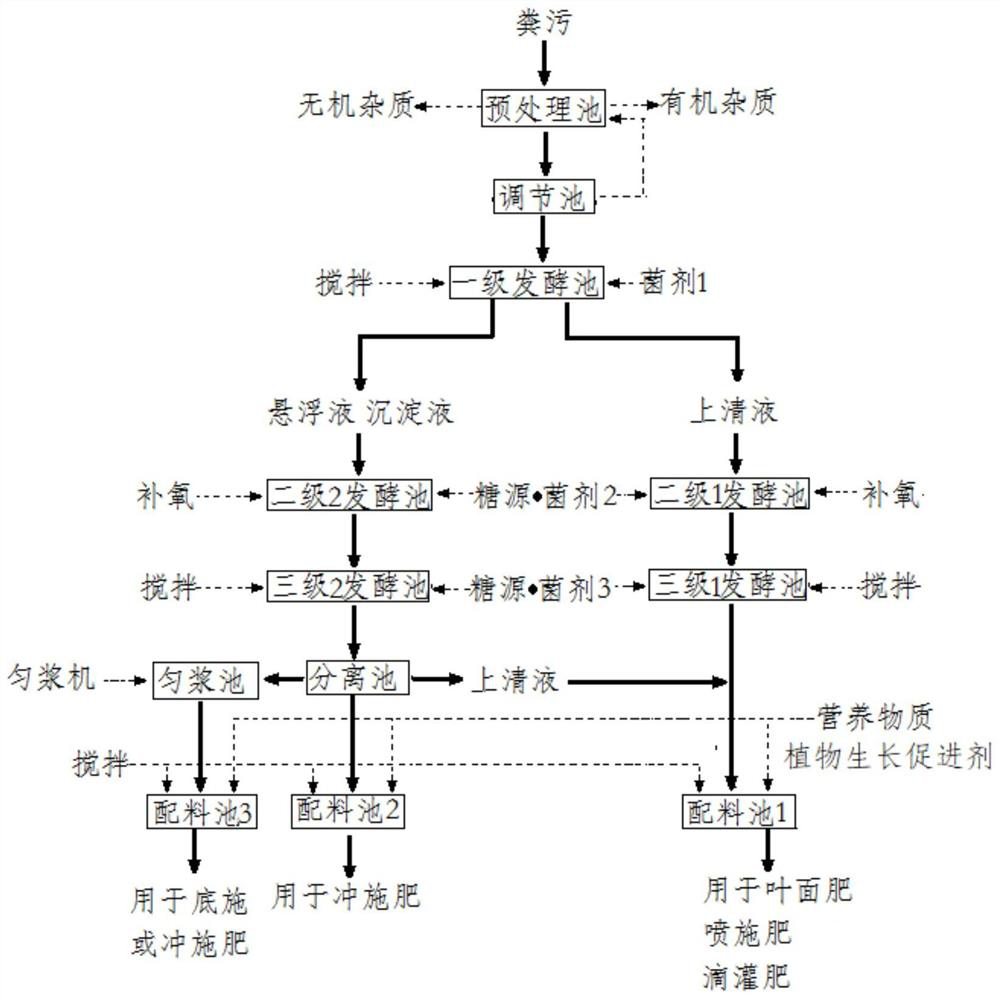

[0073] Such as figure 2 Shown, the liquid fertilizer preparation method provided by the invention comprises the following steps:

[0074] S1, pretreatment: the organic waste liquid used in the present invention is the mixture of dairy farm manure and chicken farm manure, waste liquid first enters the pretreatment tank, and the pretreatment tank is provided with a stirring device, and the bottom of the pond is provided with a settling collection pit , A sand-settling hoist is installed on the sand-settling collection pit, and the waste liquid is statically precipitated after being stirred. Inorganic impurities such as bricks, sand, metal, glass, etc. are deposited in the sand-settling collection pit at the bottom of the pool, and are removed by the sand-settling elevator. A fine grill is installed at the outlet of the pretreatment pool to remove floating and suspended organic impurities.

[0075] The mass fraction of insoluble substances in the effluent of the pretreatment ta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com