Processing system of strong-flavor tea oil

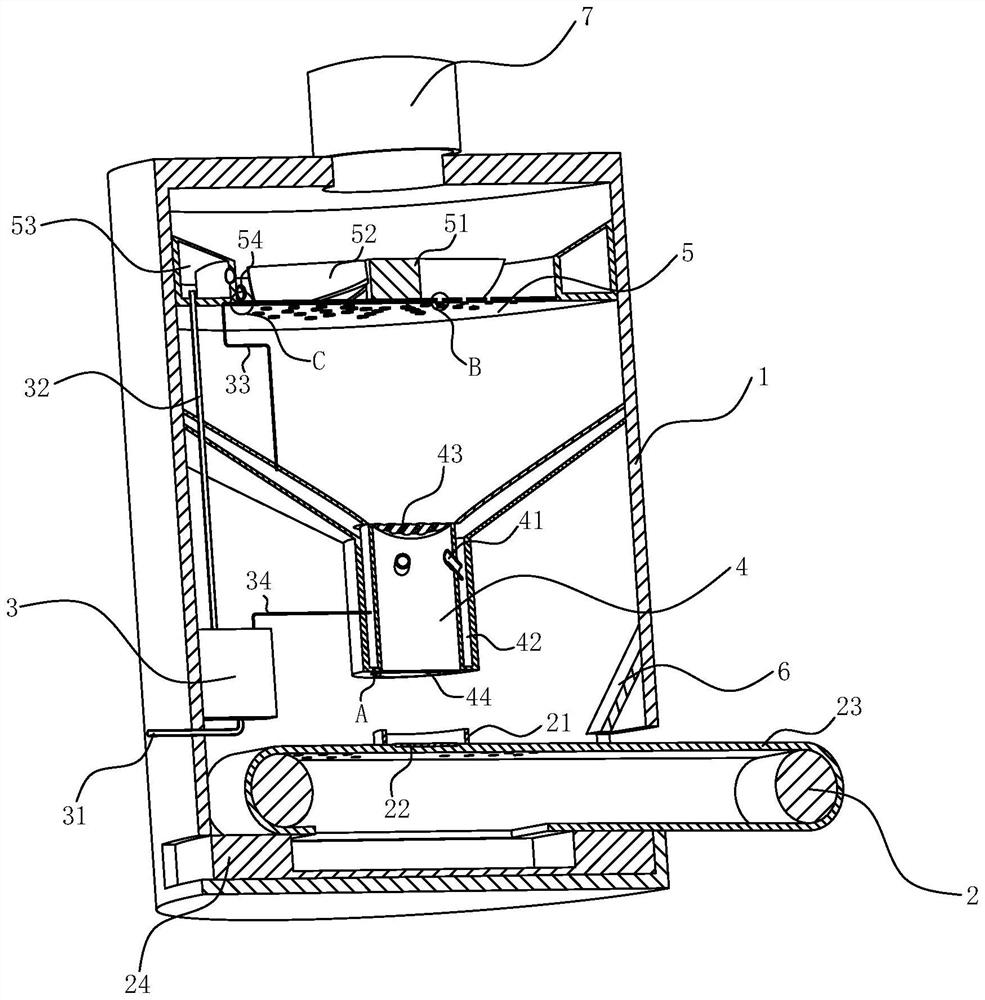

A processing system and a strong-flavor type technology, which is applied in the field of processing system of strong-flavor tea oil, can solve the problems of easy accumulation of tea seed powder and insufficient fragrance of tea oil, and achieve the effect of improving the efficiency of steaming and frying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

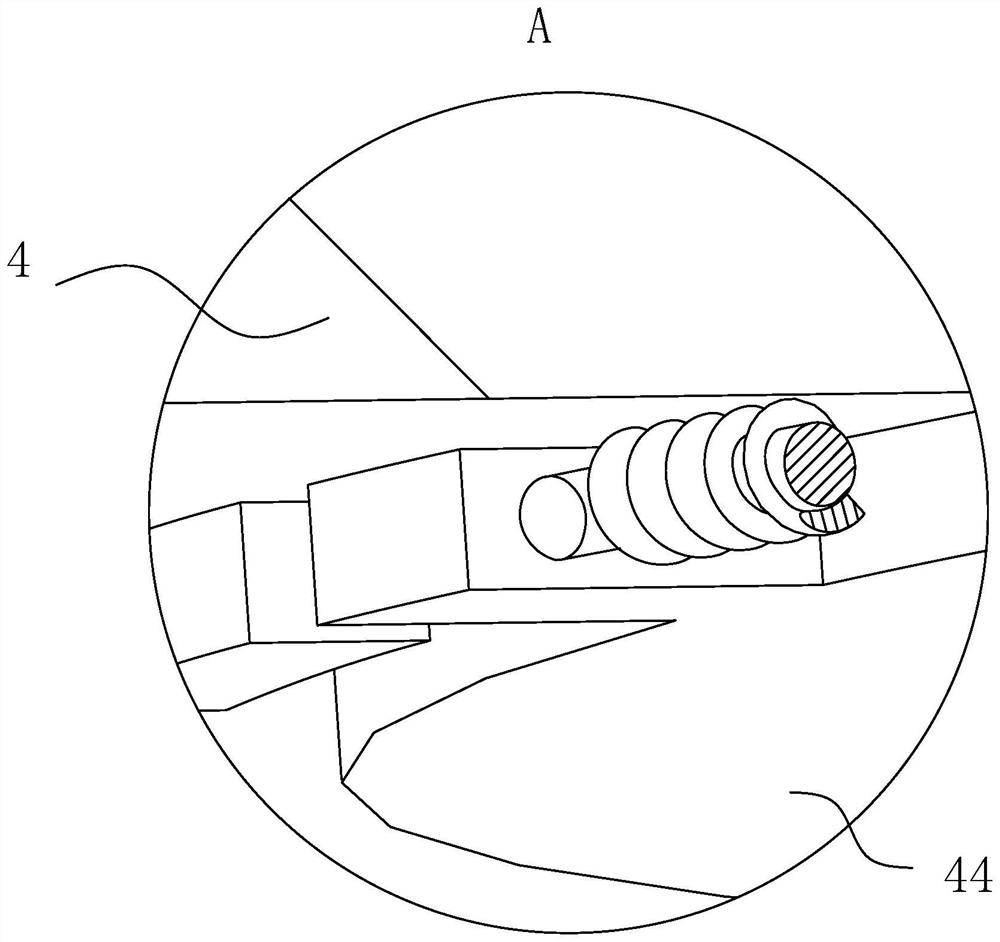

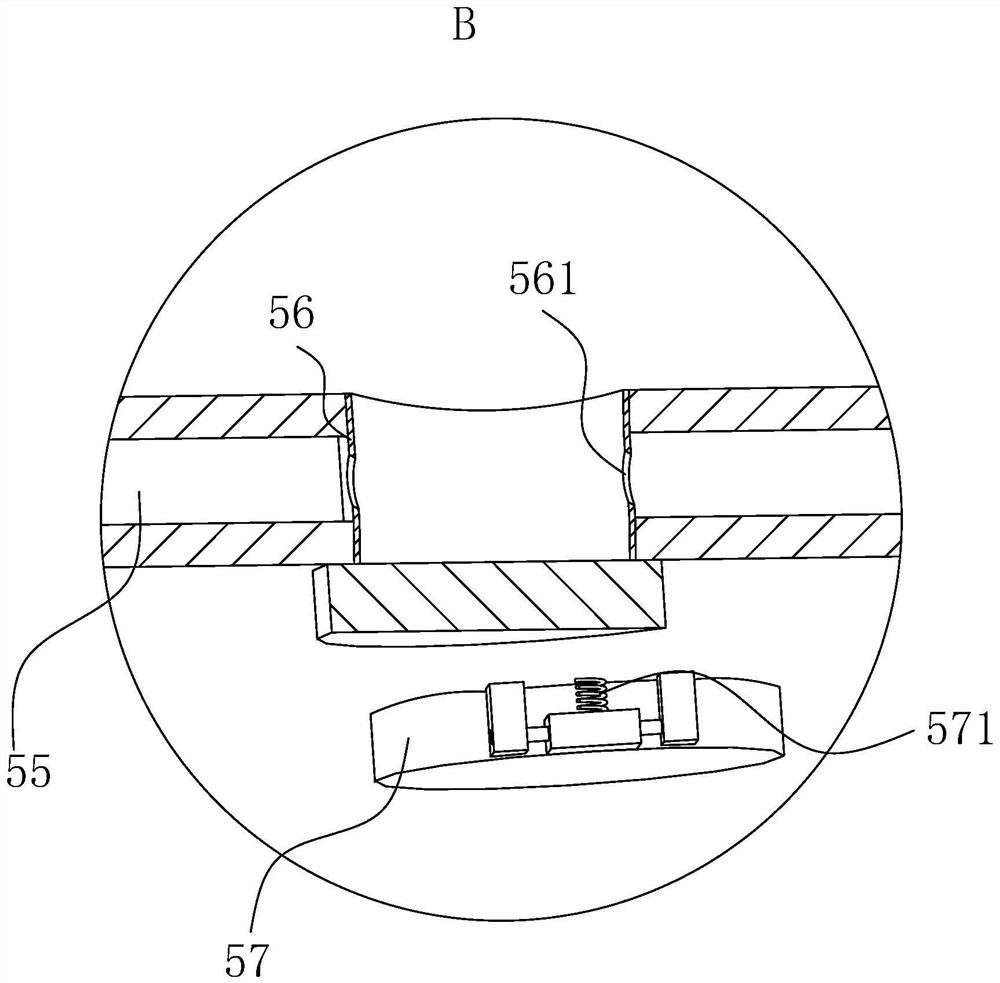

[0037] As an embodiment of the present invention, the stir-fry plate 52 is arc-shaped, and the plurality of stir-fry plates 52 are evenly distributed along the circumferential direction of the rotating shaft 51;

[0038] During work, when the stir-fry plate 52 is pushed by the high-temperature steam ejected by the steam nozzle one 54, it rotates inside the stir-fry device 5, so the stir-fry plate 52 can push the tea seed powder inside the stir-fry device 5 to rotate, and The tea seed powder is stir-fried. Since the stir-fry plate 52 is arc-shaped, when the stir-fry plate 52 touches the tea seed powder, the tea seed powder will move upward with the rotation of the stir-fry plate 52, thereby making the tea seed powder more dispersed. , the contact range between the tea seed powder and the high-temperature steam is larger, which makes the stir-frying effect of the tea seed powder better, and avoids the accumulation of the tea seed powder in a certain position during the steaming p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com