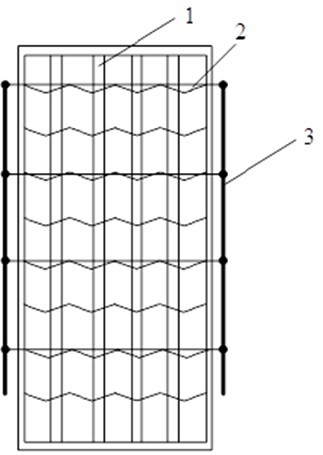

Air cooler water film cooling strengthening device and method

A technology for strengthening devices and air coolers, applied in the direction of heat exchangers, indirect heat exchangers, heat exchange equipment, etc., can solve the problems of low utilization rate of latent heat and poor heat exchange efficiency, and achieve simple structure, high cooling efficiency, Enhance the effect of water film vaporization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

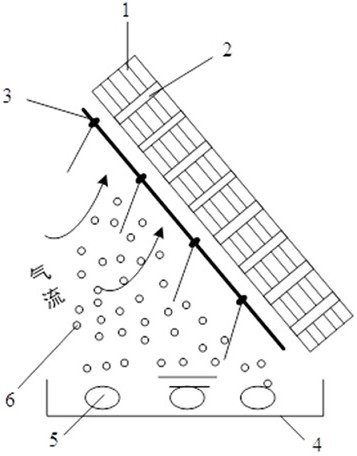

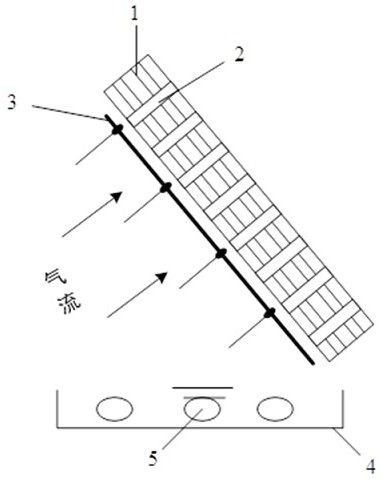

[0034] Embodiment 1: The water film cooling strengthening method of the air cooler adopts the following specific processes.

[0035] Adjust the angle between the whole channel 1 of the cooled medium and the horizontal plane to 30°, the wind speed of the film distribution process and the water film vaporization process are 0.5m / s and 2m / s respectively, the film distribution process: the water film vaporization time-to-length ratio = 1:3, and the inner angle of the corrugation 160°; at the same time, set up a conventional horizontal light tube air cooler as a comparison, and keep the air volume, water distribution volume, water inlet water volume and water temperature consistent with the system, and record the temperature of the water inlet and water outlet detectors in Table 1.

Embodiment 2

[0036] Embodiment 2: The method for strengthening the water film cooling of the air cooler adopts the following specific processes.

[0037] Adjust the angle between the whole channel of the cooled medium and the horizontal plane to 45°. The wind speeds of the film distribution process and the water film vaporization process are 0.5m / s and 2m / s respectively. °; At the same time, a conventional horizontal light tube air cooler was set as a control, and the air volume, water distribution volume, water intake volume and water temperature were consistent with the system, and the temperature of the water inlet and water outlet detectors was recorded at the same time, see Table 1.

Embodiment 3

[0038] Embodiment 3: The water film cooling strengthening method of the air cooler adopts the following specific processes.

[0039] Adjust the angle between the whole channel of the cooled medium and the horizontal plane to 60°. The wind speeds of the film distribution process and the water film vaporization process are 0.5m / s and 2m / s respectively. °; At the same time, a conventional horizontal light tube air cooler was set as a control, and the air volume, water distribution volume, water intake volume and water temperature were consistent with the system, and the temperature of the water inlet and water outlet detectors was recorded at the same time, see Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com