System and method for controlling ignition of internal combustion engine

An internal combustion engine and ignition control technology, which is applied in the direction of engine ignition, ignition energy generated by generators, spark ignition controllers, etc., can solve the problems of increasing the volume and cost of the ignition system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

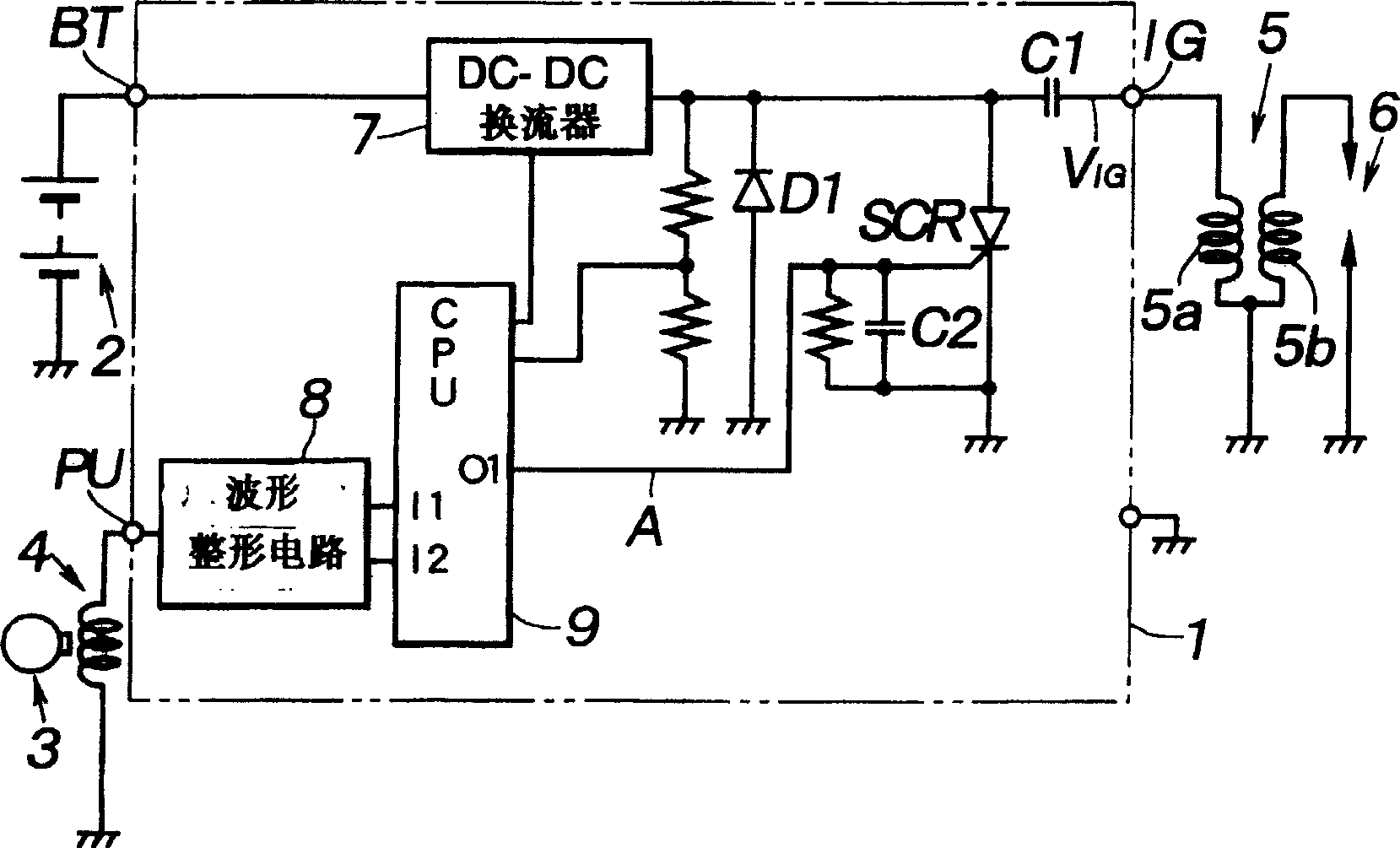

[0017] figure 1 is a circuit diagram of an ignition system for a motorcycle internal combustion engine according to the present invention. Such as figure 1 As shown, the battery 2 is connected to the voltage terminal BT of the CDI circuit 1 . The pulse generator coil 4 is connected to the pulse input terminal PU for generating a pulse-shaped ignition timing reference signal as the alternator 3 rotates, for example. The primary side coil 5 a of the ignition coil 5 is connected to the output terminal IG, and the spark plug 6 is connected to the secondary side coil 5 b of the ignition coil 5 .

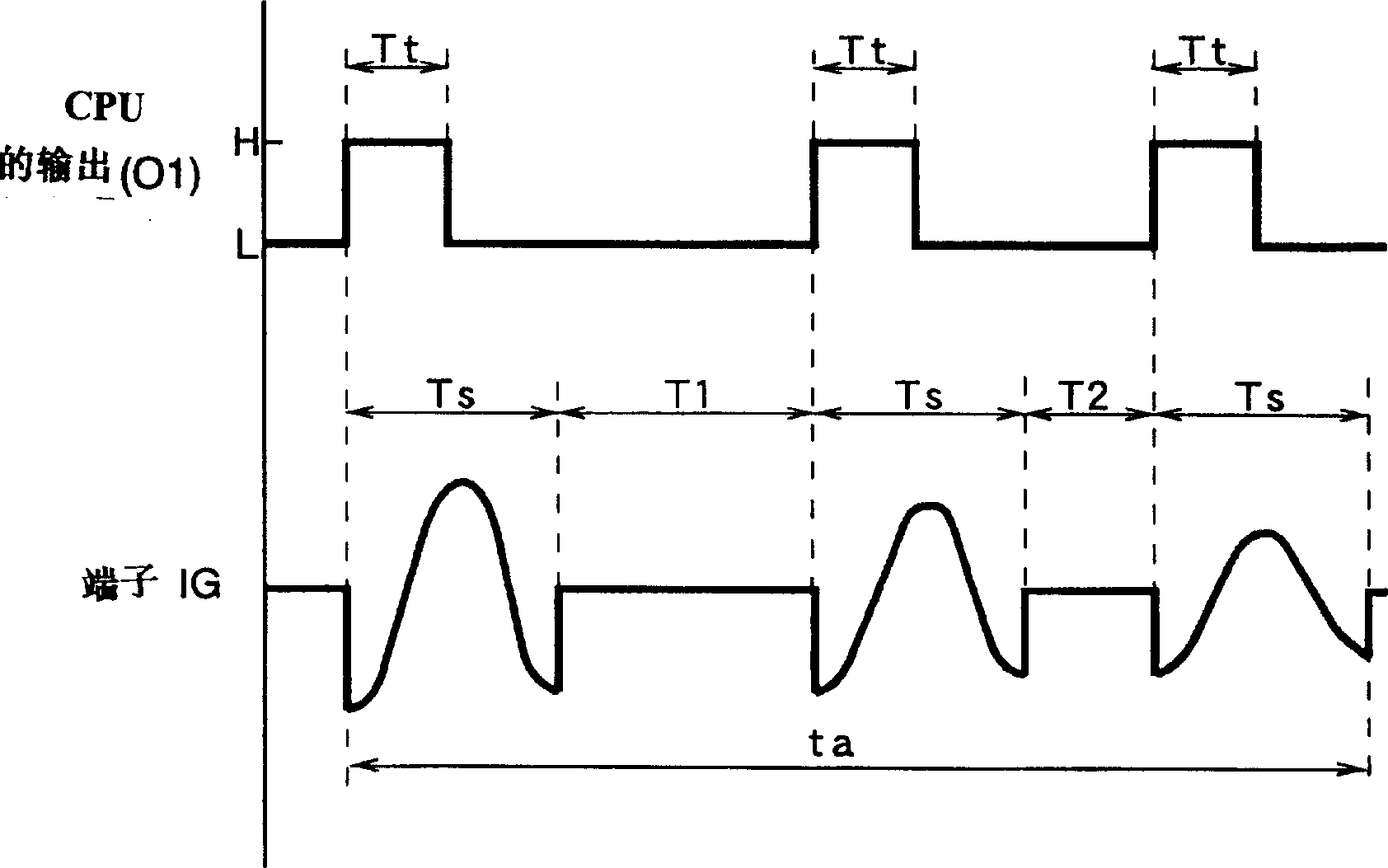

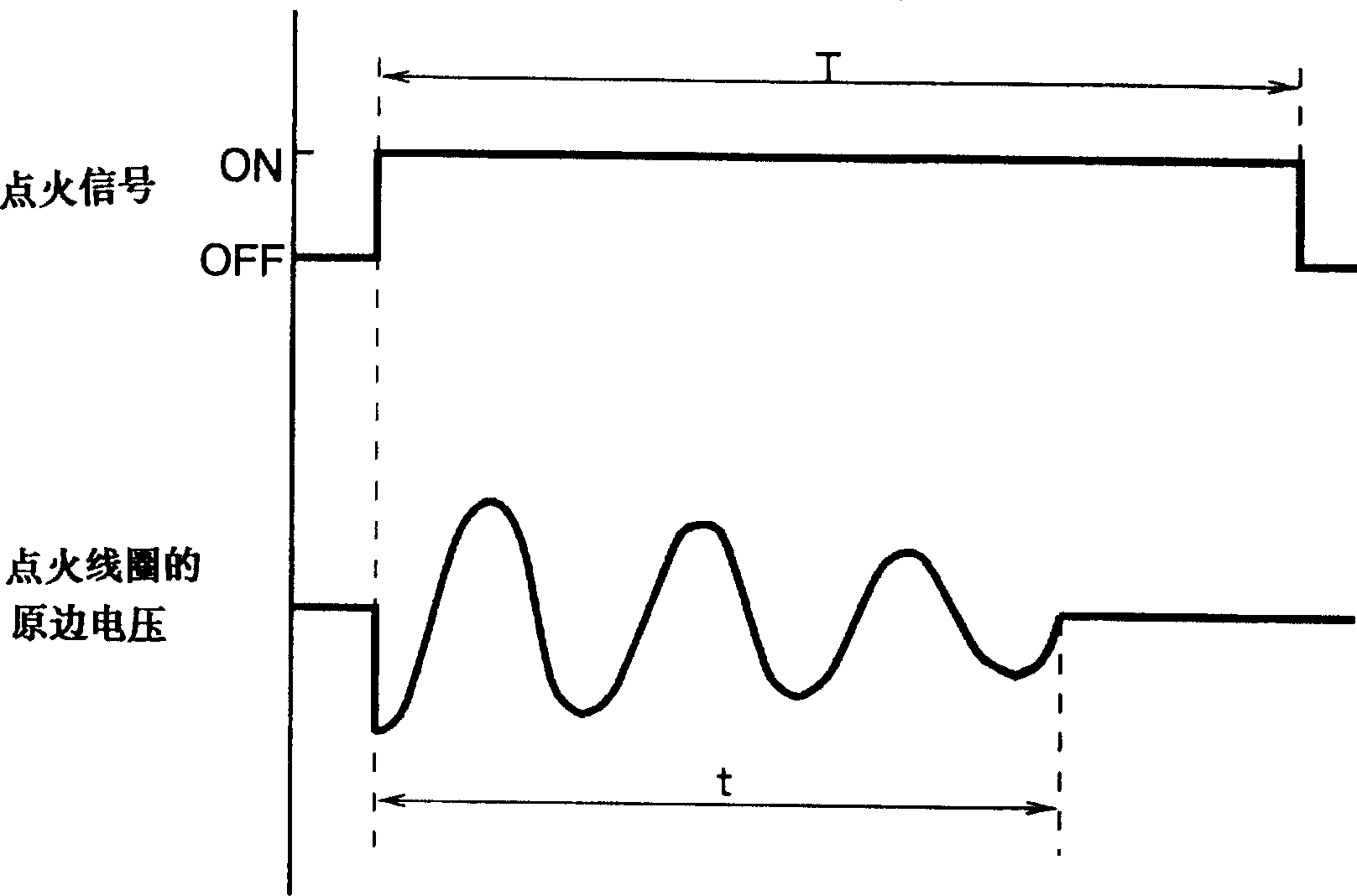

[0018] In the CDI circuit 1, the DC-DC converter 7 and the main capacitor C1 are connected in series in this order on the power supply line extending from the terminal BT to the terminal IG. In addition, the main capacitor C1 is connected to the primary coil 5a of the ignition coil 5 through the terminal IG. Each ignition timing reference signal supplied to terminal PU is converted ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com