Miniature contact element and ultramicro rectangular electric connector using same

A technology for electrical connectors and contacts, which is applied to contact parts, two-part connection devices, connections, etc., can solve problems such as low production efficiency, cumbersome twist needle processing technology, and affecting product reliability, so as to reduce porosity and good Elasticity, fast loading and unloading effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

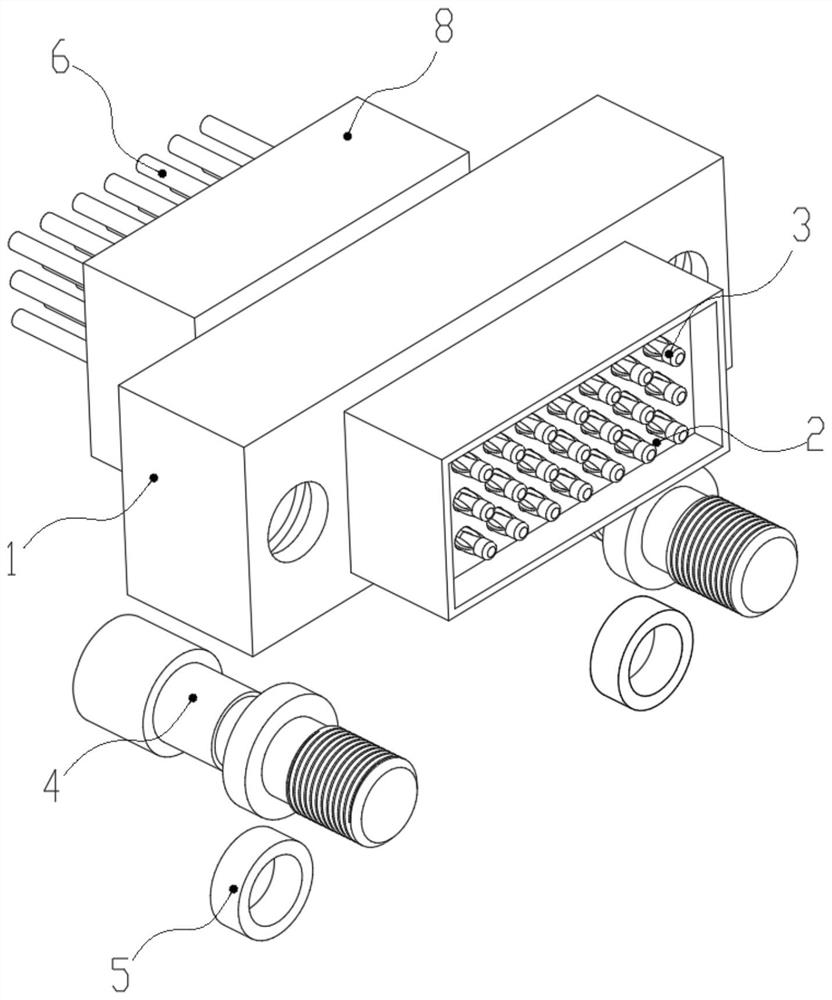

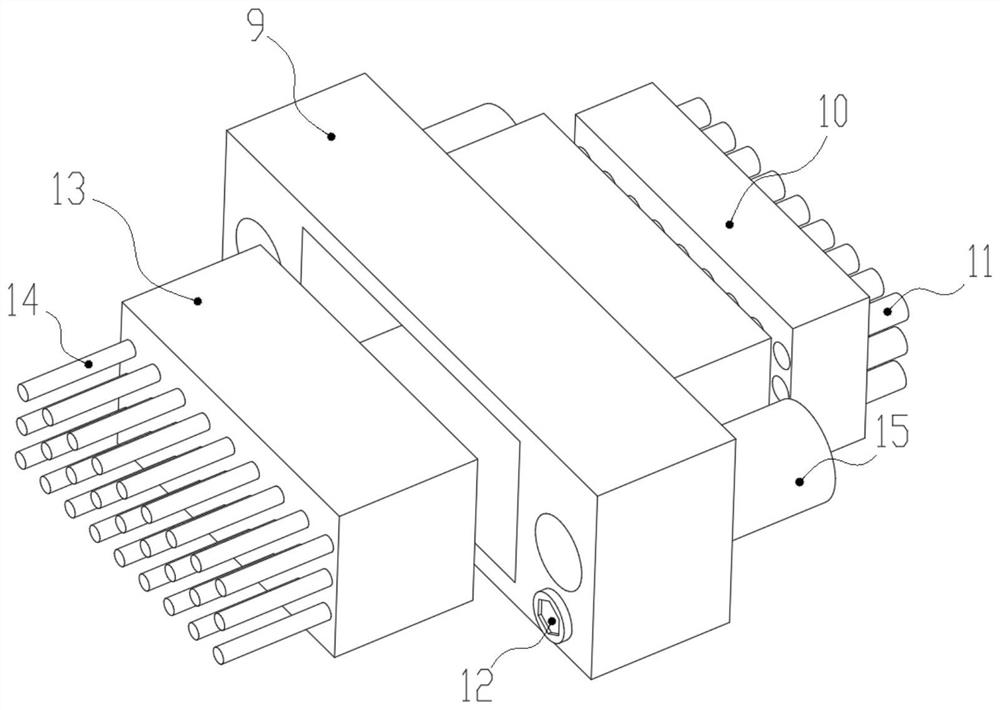

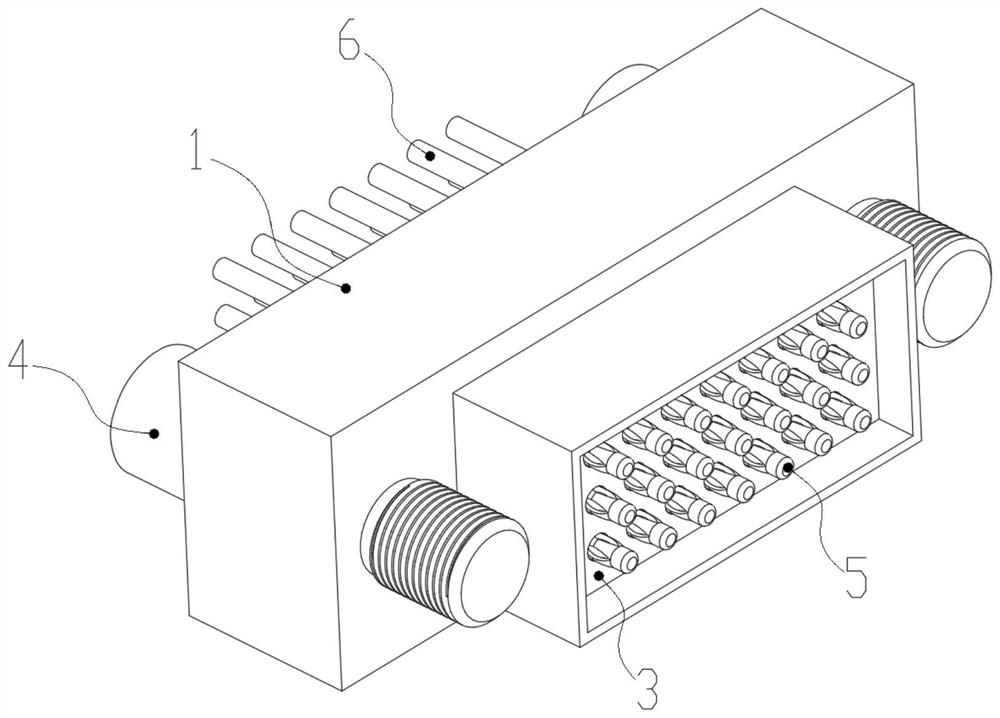

[0045] see Figure 1-9 , an embodiment provided by the present invention: a small-sized contact piece and an ultra-micro rectangular electrical connector using the contact piece, including a plug and a socket adapted to the plug, and the plug includes a head housing 1, a pin insulator 2 , pin 3 of toothed spring, hexagon socket bolt 4, fixing ring 5, connecting cable 6 and first black resin glue 8;

[0046] The first black resin glue 8 for protection is fixedly installed on the bottom of the inner end surface of the head-containing shell 1, and the inner end surface of the first black resin glue 8 is evenly and equidistantly fixedly connected with the connecting cables 6 for connection, the head-containing shell 1 The inner end surface of the inner end face is symmetrically rotated and snapped with a fixed ring 5, and the inner end face of the head-containing shell 1 is rotated and snapped with a hexagonal socket bolt 4 through the fixed ring 5, and the upper end face of the h...

Embodiment 2

[0065] On the basis of Example 1, such as Figure 10 As shown, the threaded connection shaft 41 is slidingly clamped with the positioning clamp 42 through the insertion sliding shaft 410, and the outside of the threaded connection shaft 41 and the positioning clamp 42 are evenly and equidistantly slidingly clamped with four sets of positioning inserting rods 48. The connecting shaft 41 and the positioning clamp 42 are elastically fixedly connected by the connecting spring 49. The outer end surface of the fixed sliding shaft 44 is evenly and equidistantly provided with anti-slip lines 47, and the outer end surface of the fixed sliding shaft 44 is provided with a connecting circle near the opening. Angle 46.

[0066] During the implementation of this embodiment, if the positioning is inaccurate during positioning, the threaded connection shaft 41 can be elastically contracted by the positioning insertion rod 48 and the connection spring 49, so that the threaded connection shaft ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com