Electrical cabinet with slidable turnover type mounting plate

A technology for mounting boards and electrical cabinets, applied in the field of electrical cabinets, can solve the problems that the mounting board equipment cannot be installed more flexibly, cannot be moved and turned, and cannot be adjusted in the angle of the mounting board, etc. The effect of improving the heat dissipation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

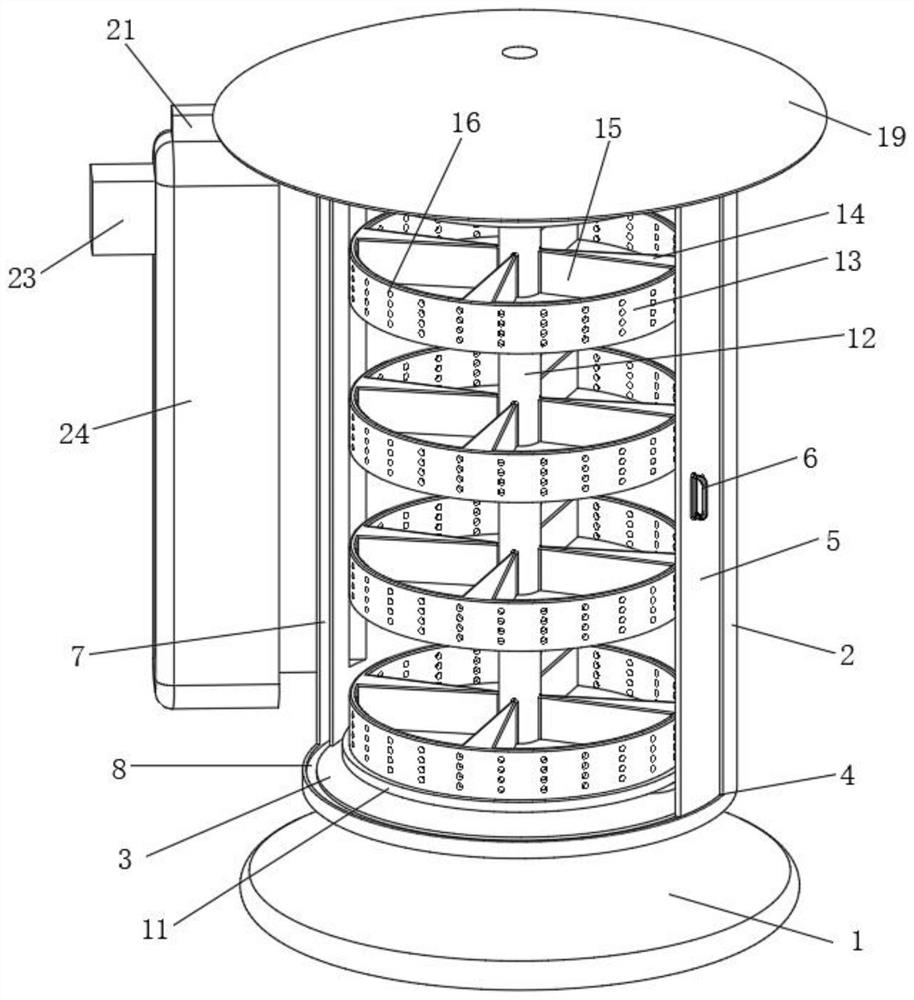

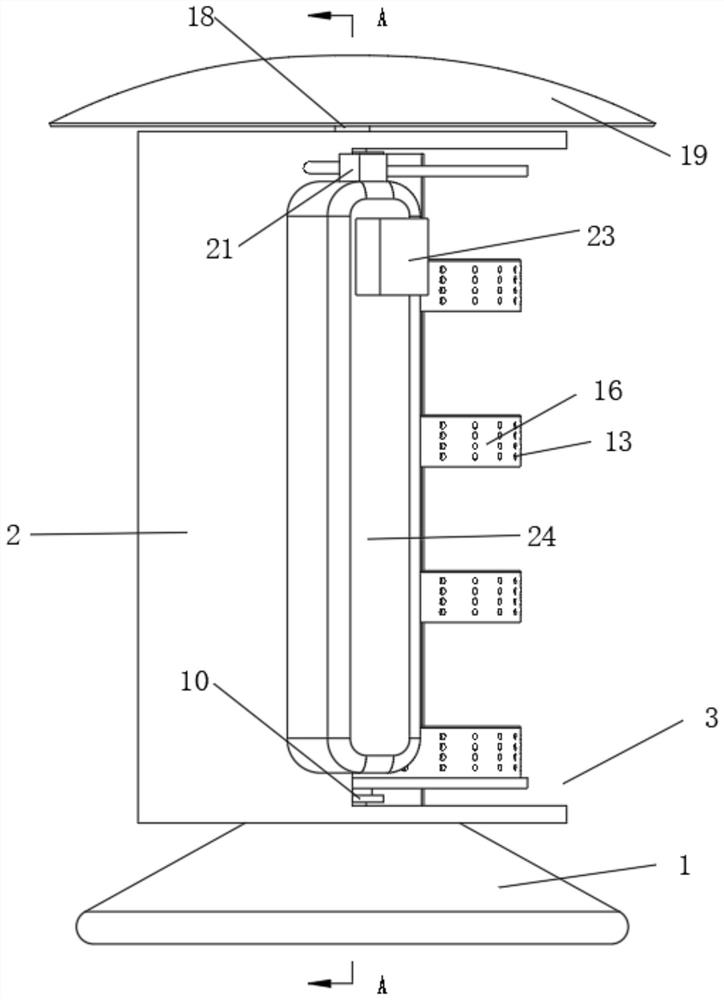

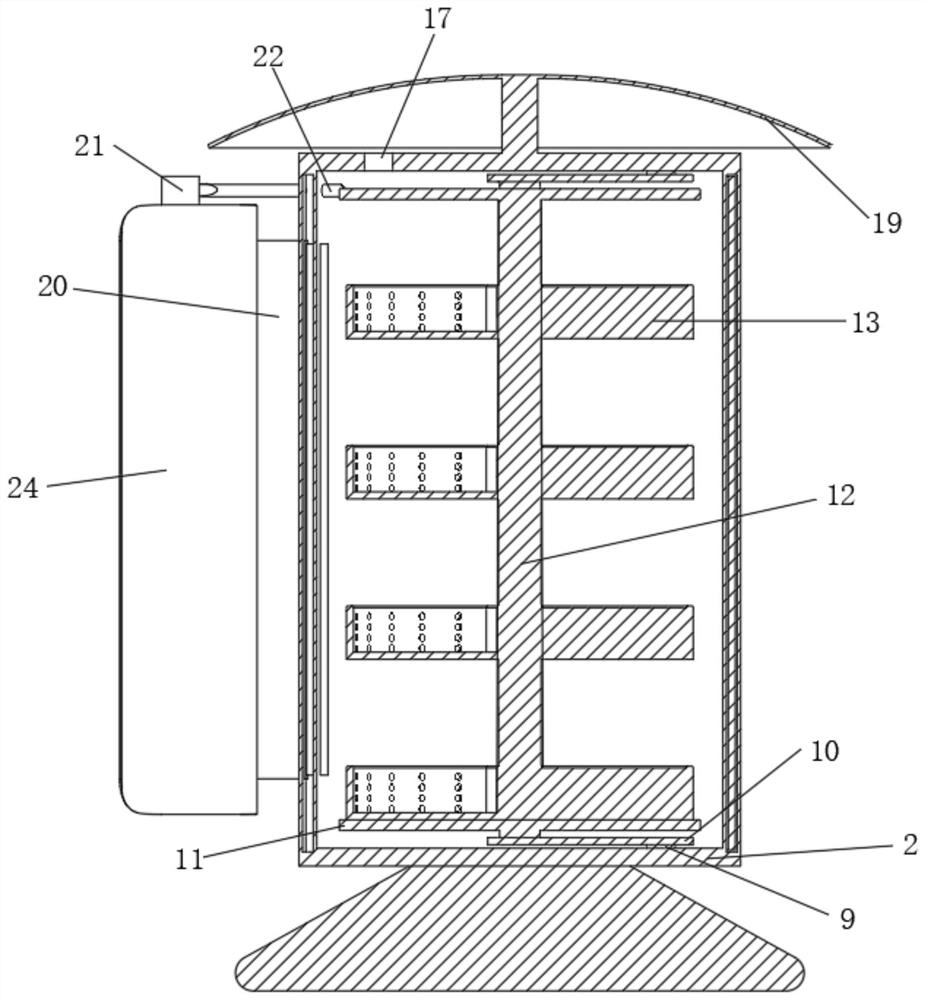

[0028] see Figure 1-Figure 5 , the present invention provides the following technical solutions: an electrical cabinet with a slidable flip-up mounting plate includes a cabinet body 2, a sliding door mechanism is arranged on the front side of the cabinet body 2, and a connecting shaft 12 is connected to the inside of the cabinet body 2 through a flip mechanism, The connecting shaft 12 is provided with multiple sets of equidistant placement mechanisms, the side wall of the cabinet body 2 is provided with a heat dissipation mechanism, and the turning mechanism includes two hinge shafts 9, and the two hinge shafts 9 are respectively rotatably connected to the upper and lower sides of the cabinet body 2. On the inner wall, the two hinge shafts 9 are rotatably connected to an overturning plate 10 at one end close to each other;

[0029]In a specific embodiment of the present invention, the entire electrical cabinet has a reasonable structure, ingenious conception, flexible use, co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com