Crystal membrane separation equipment for producing fluorescent whitening agent

A fluorescent whitening agent and crystal technology, applied in the direction of solution crystallization, evaporation separation crystallization, etc., can solve the problems of complex operation, waste of time, insufficient heating and mixing effect, etc., achieve ingenious structure setting, improve heat insulation effect, and save operation time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

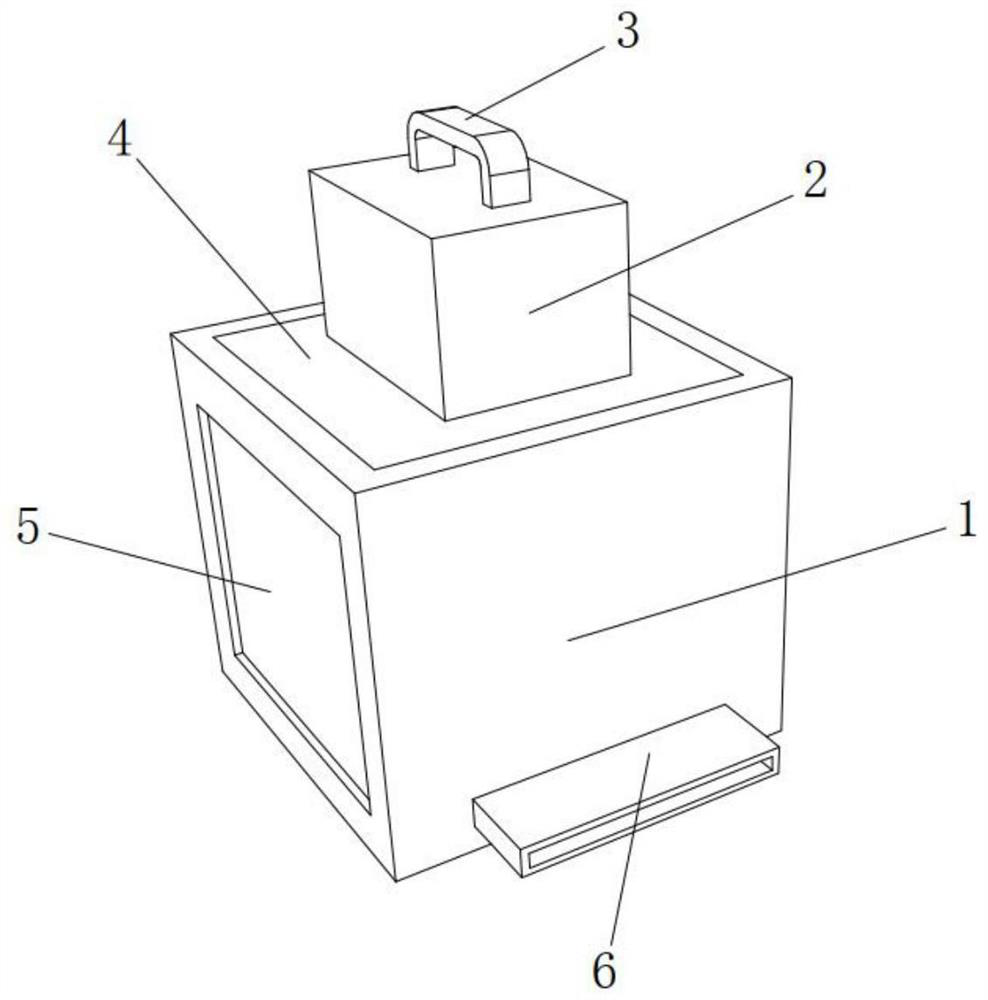

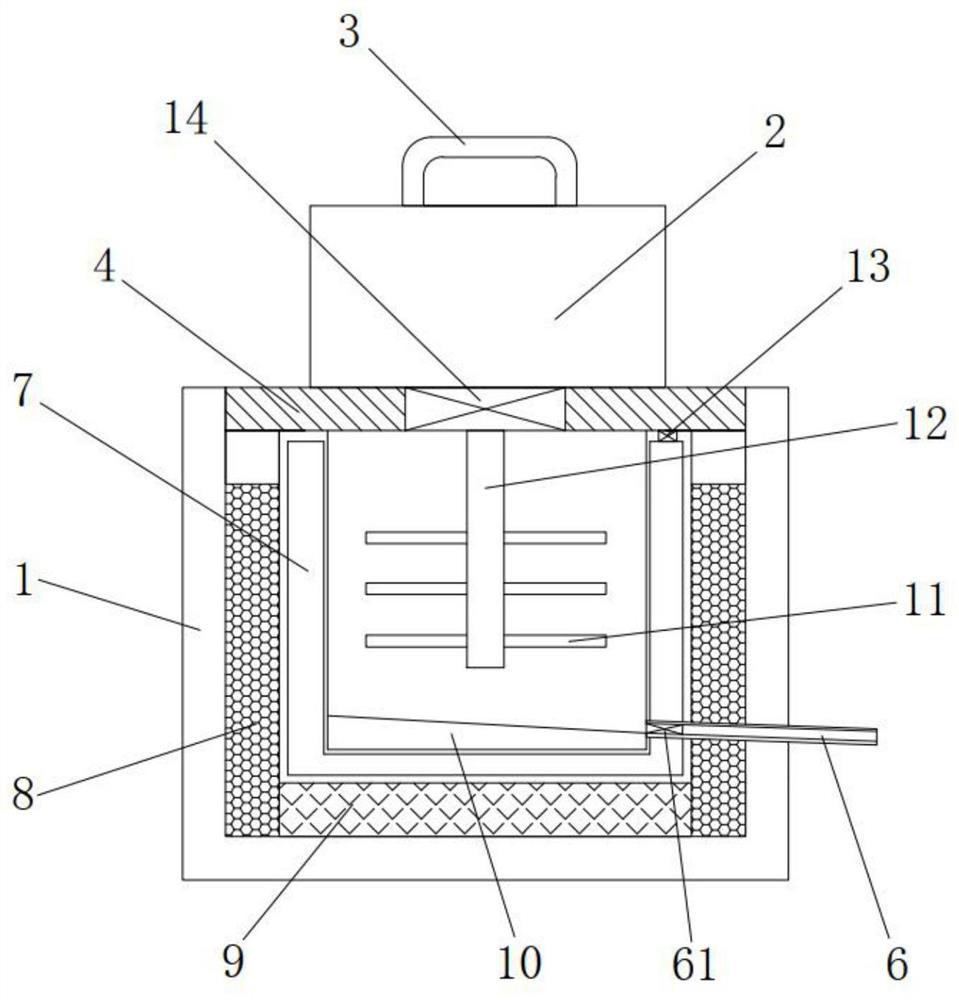

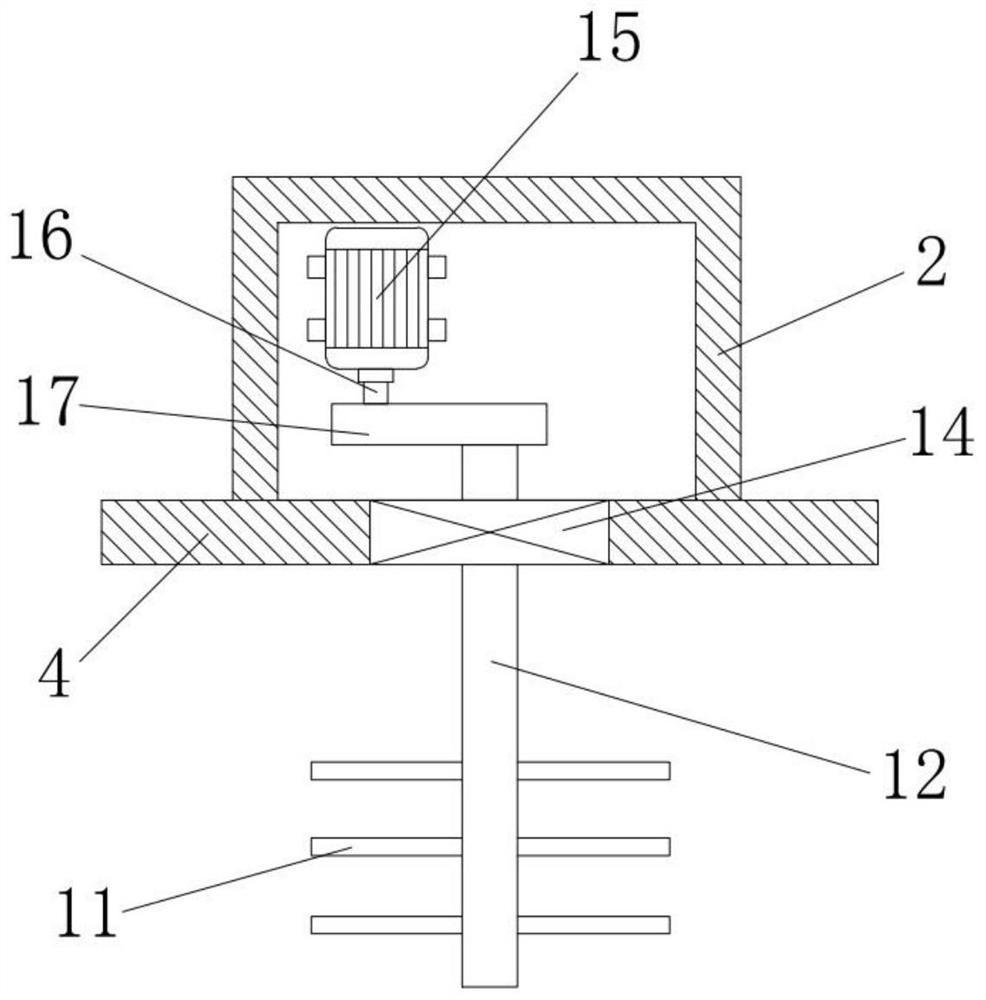

[0026] see Figure 1-3 , a crystal film analysis equipment for producing fluorescent whitening agent, comprising a main body casing 1 for producing fluorescent whitening agent, the front end of the main body casing 1 is provided with an observation window 5 capable of observing the state of crystal film analysis inside the box; the main body The shell 1 is provided with a crystal analysis box 7, the crystal analysis box 7 is a "concave" shaped hollow structure, the crystal analysis box 7 is provided with a perfusion plug 13, the perfusion plug 13 is embedded in the crystal The opening and closing structure at one end of the top of the crystal analysis box 7; the bottom of the crystal analysis box 7 is provided with a heating device 9; the top of the crystal analysis box 7 is provided with a partition 4, and the partition 4 is provided with a stirri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com