Flush type galangal stem leaf and root hair separation equipment

A technology for separating equipment and galangal, which is applied in metal processing and other directions to achieve the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

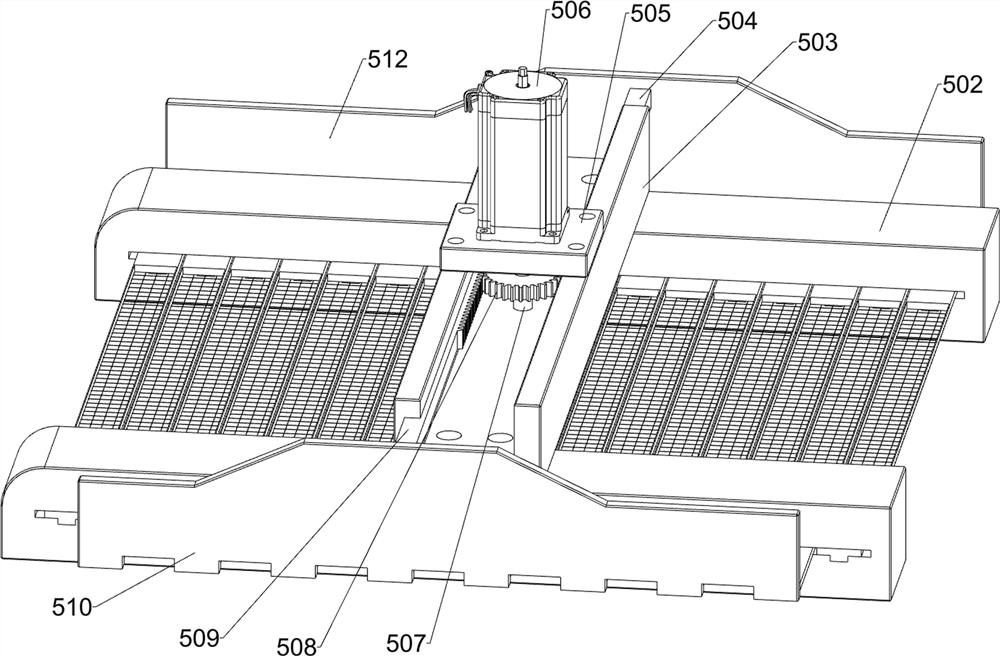

[0035] A kind of flat type galangal stem leaf and root hair separation equipment, such as Figure 1-8 As shown, it includes an installation cabin 1, an installation frame 2, a stem-leaf separation system 4 and a root and hair removal system 5; the left side of the installation cabin 1 is provided with an installation frame 2; the left part of the installation cabin 1 is connected with a separation stem-leaf system 4 The stem and leaf separation system 4 is connected to the installation frame 2; the root and hair removal system 5 is connected to the upper part of the installation frame 2;

[0036] When working, first place the galangal pretreatment equipment at the desired location, place the installation cabin 1 and the installation frame 2 on a stable position, first manually put the galangal in rows into the stem-leaf separation system 4, and pass The separation stem-leaf system 4 hooks the rhizome part of the galangal, so that the galangal is hung upside down. When the gala...

Embodiment 2

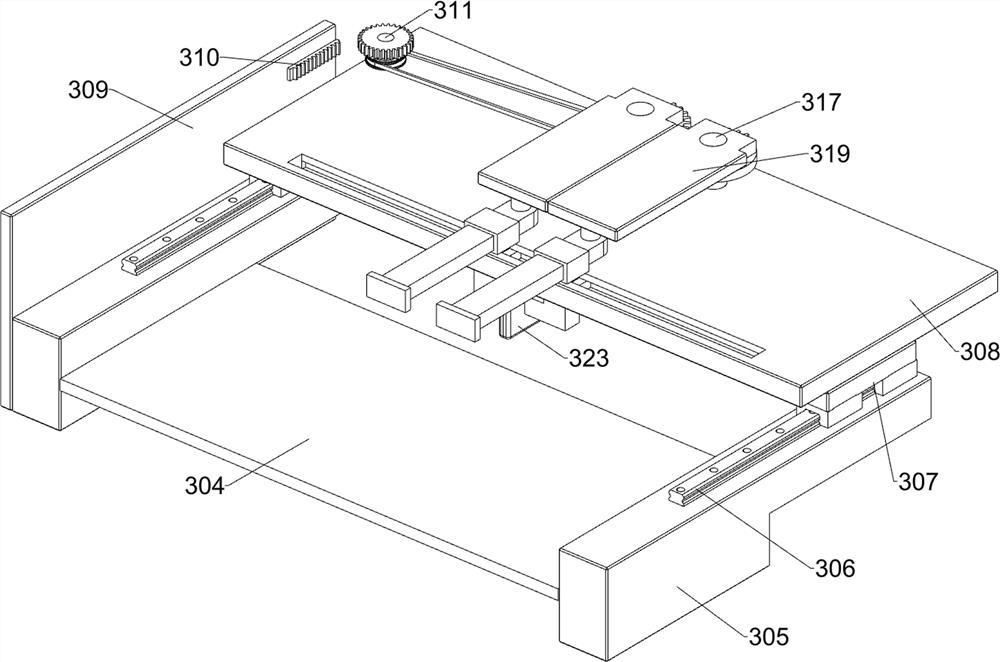

[0046]On the basis of Example 1, such as figure 1 and Figure 9-11 As shown, it also includes a leveling system 3; the right part of the installation cabin 1 is connected with a leveling system 3; the leveling system 3 includes a first installation shaft seat 301, a first electric push rod 302, a second installation shaft seat 303, Loading and placing plate 304, first mounting plate 305, first electric slide rail 306, fixed plate 307, second mounting plate 308, mounting side plate 309, first rack 310, first rotating shaft 311, first transmission wheel 312 , the first straight gear 313, the second rotating shaft 314, the second transmission wheel 315, the first missing gear 316, the third rotating shaft 317, the second missing gear 318, the rotating plate 319, the fourth rotating shaft 320, the transmission rod 321, L-shaped The slider 322 and the dial plate 323; the right front part and the right rear part of the installation cabin 1 are respectively equipped with a first ins...

Embodiment 3

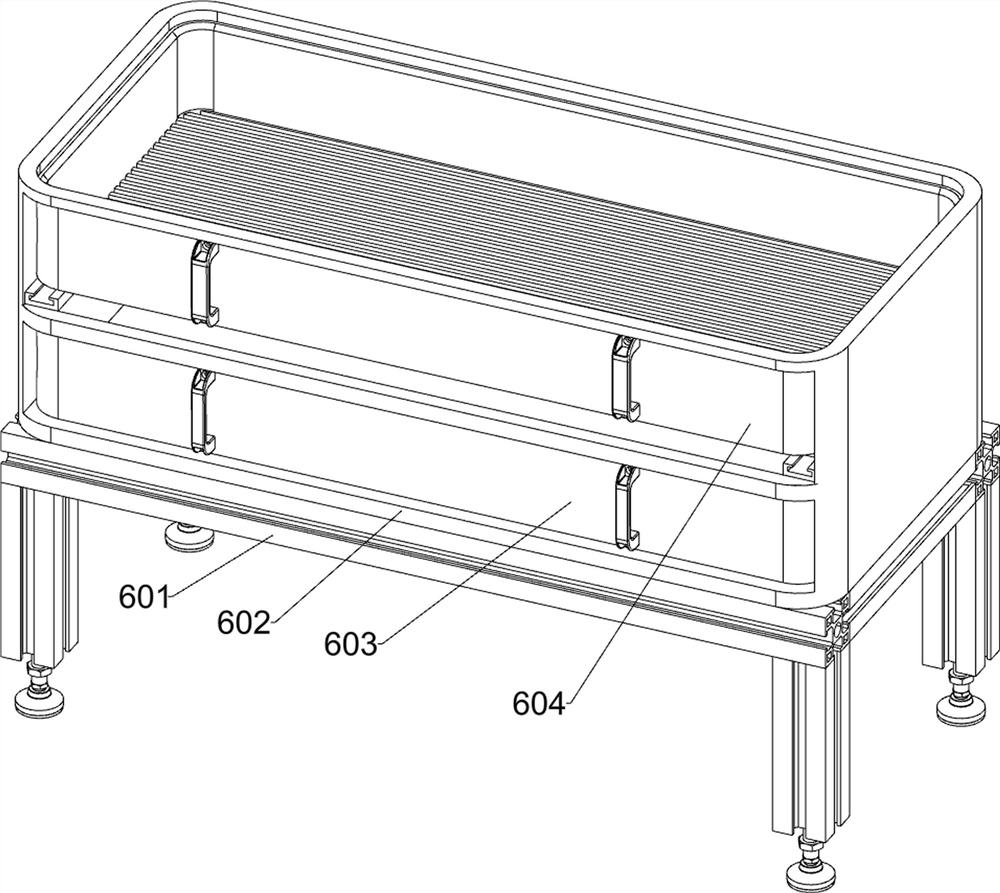

[0049] On the basis of Example 2, such as figure 1 and Figure 12 As shown, a collection system 6 is also included; the left side of the installation frame 2 is connected to the collection system 6; the collection system 6 includes a collection bracket 601, a collection box 602, a root collection drawer 603, a finished product collection drawer 604 and a chute plate 605 The left side of the installation frame 2 is provided with a collection bracket 601; the upper surface of the collection bracket 601 is fixedly connected with a collection box 602 by bolts; Finished product collection drawer 604 .

[0050] The bottom plate of the finished product collection drawer 604 is configured as a sub-sieve plate for frictionally fractured galangal root hairs.

[0051] When the cleaned galangal and the broken roots are sent to the collection box 602 by the conveyor 501, the cleaned galangal will be collected by the finished product collection drawer 604, and the broken roots will pass t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com