Environment-friendly hydrometric cableway oiling machine for water conservancy detection

A hydrological cableway and environment-friendly technology, applied in metal processing equipment, paint spray booths, manufacturing tools, etc., can solve the problems of insufficient uniformity of fueling, waste of environmental protection, environmental pollution resources, etc., so as to improve the effect of fueling and maintenance, and improve the environmental protection of use. , the effect of preventing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

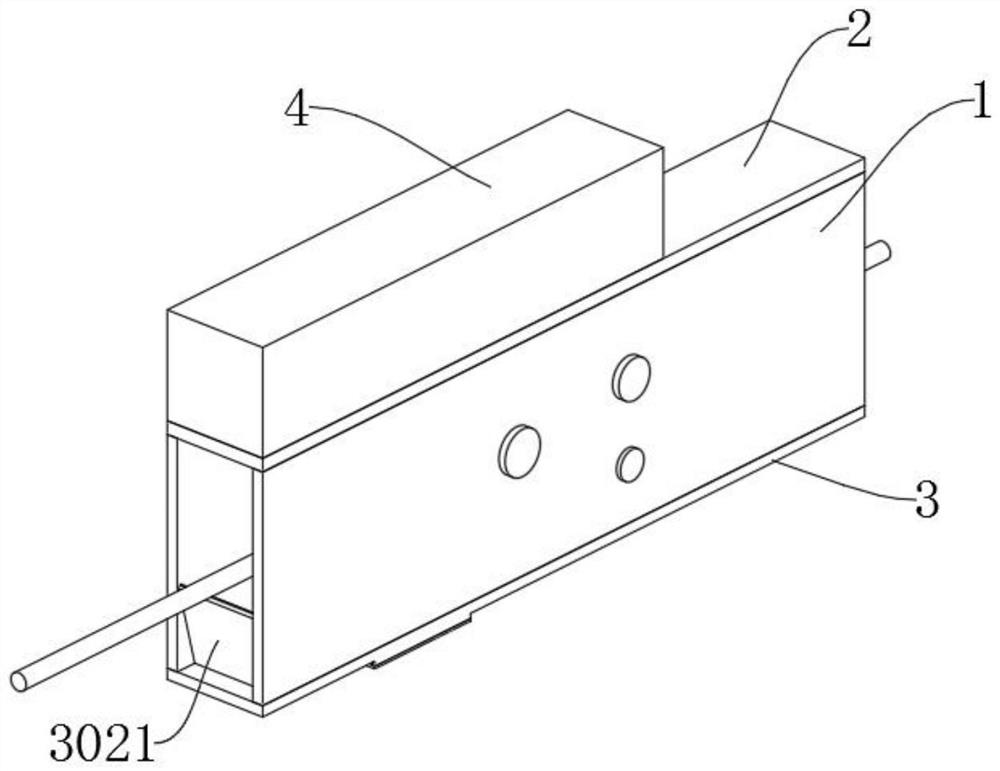

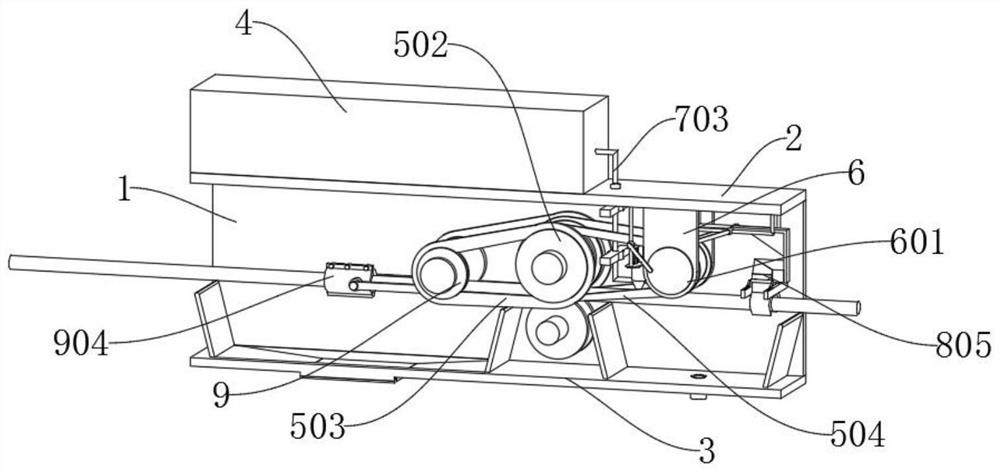

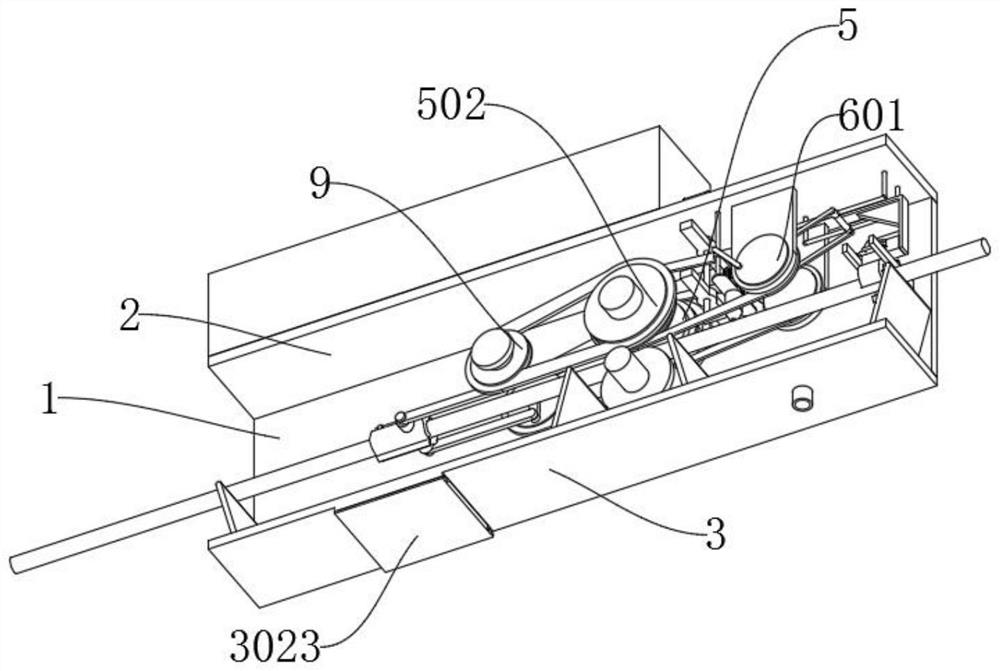

[0086] Example: please refer to Figure 1 to Figure 10 :

[0087] The present invention proposes an environment-friendly hydrological cable channel refueling machine for water conservancy testing, comprising: a carrying body 1, the cross-sectional shape of the carrying main body 1 is a "rectangle", an assembly top cover 2 is provided on the top of the carrying body 1, and the top of the assembly top cover 2 is provided An oil storage tank 4 is installed, a bearing base 3 is arranged at the bottom of the bearing body 1, a first collection structure is arranged at one end of the top of the bearing base 3, and a second collection structure is arranged at the other end of the top of the bearing base 3; It is rotatably installed on the inner side of the bearing main body 1, and the outer side of the driving carrier wheel 5 is provided with a driving structure. The driving structure includes an assembly shaft 501, and the assembly shaft 501 is arranged on both sides of the driving c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com