Steam generator of clothes treatment device and washing machine

A technology for clothes treatment devices and steam generators, which is applied to other washing machines, washing devices, textiles and papermaking, etc., and can solve the problems of limited internal space of washing machines, large overall size of steam generators, and large heating pipes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

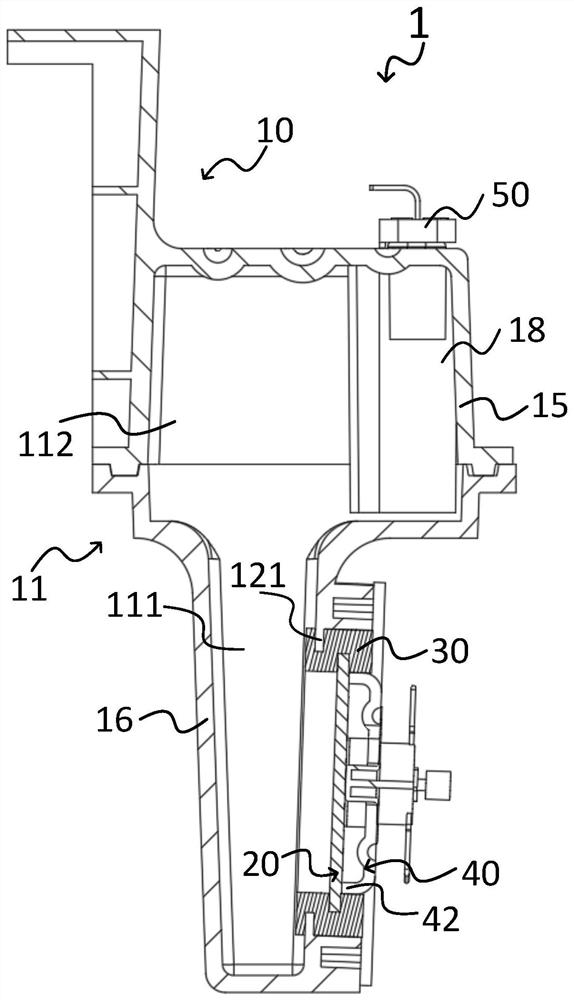

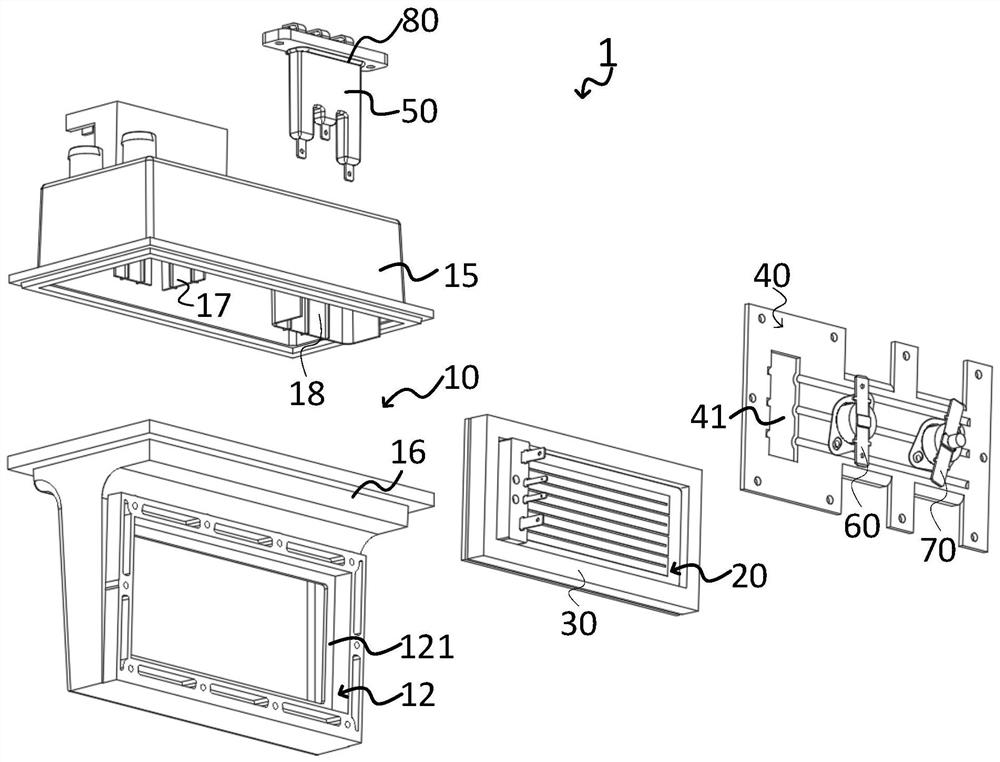

[0049] The present invention provides a steam generator of a clothes treatment device, such as figure 1 As shown, it includes a generator body 1 arranged in the laundry treatment device, and the generator body 1 includes:

[0050] The casing 10 forms the shell structure of the generator body 1 and is used to form a cavity 11 for storage. The cavity 11 is a sealed space, and the cavity 11 can be used to store liquid water and / or steam;

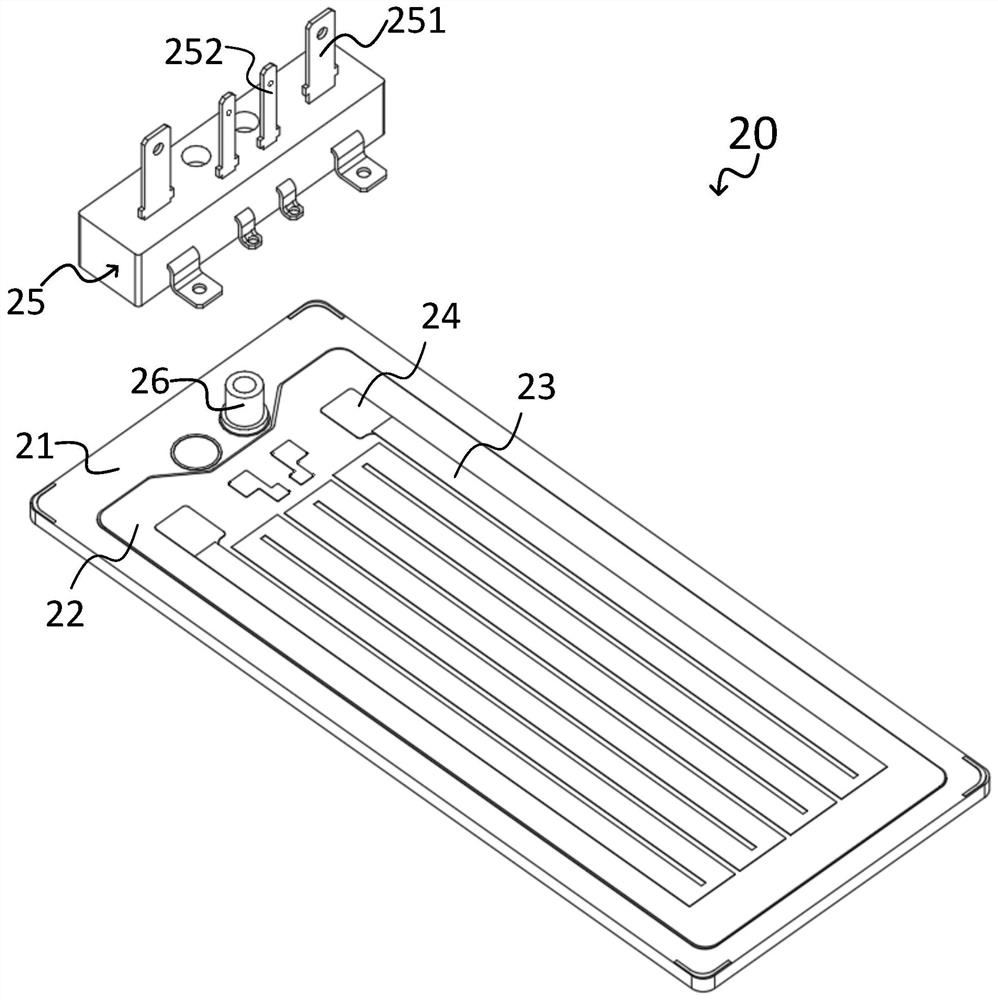

[0051] The thick-film heating element 20 is in a plate-like structure, the plate-like structure is thin, the contact area with water is large, and the heating speed is fast; the thick-film heating element 20 is arranged on the housing 10 to heat the liquid water in the cavity 11 to The steam is formed and exported to the clothes holding cylinder of the clothes care device; the liquid water in the cavity 11 contacts the heating end of the thick film heating element 20, when the thick film heating element 20 is working, the water is heated to for...

Embodiment 2

[0081] The present invention provides a washing machine, which comprises a casing, in which the steam generator of the above-mentioned clothes treatment device is arranged; the water inlet 14 of the generator body 1 is connected with the water pipe in the casing of the washing machine, and the generator body 1 The air outlet 13 is in communication with the inner cylinder of the washing machine to provide steam to the inner cylinder of the washing machine. When the user turns on the steam decontamination or steam drying or steam wrinkle removal or steam sterilization mode of the washing machine, the water inlet 14 of the generator body 1 starts to flow a preset amount of water, and the thick film heating element 20 starts heating at the same time, and the water touches the thick film The membrane heating component 20 is heated to form steam, so as to provide steam to the inner cylinder of the washing machine, so as to realize the functions of decontamination, drying, wrinkle rem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Horizontal angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com