Smokeless heating furnace

A heating stove and furnace body technology, which is applied in the direction of household stoves/stoves, household heating, lighting and heating equipment, etc., can solve the problems of reduced user comfort of heating stoves, flooded with smoke, etc., and achieves reduced contact area, reduced smoke, The effect of reducing dust particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

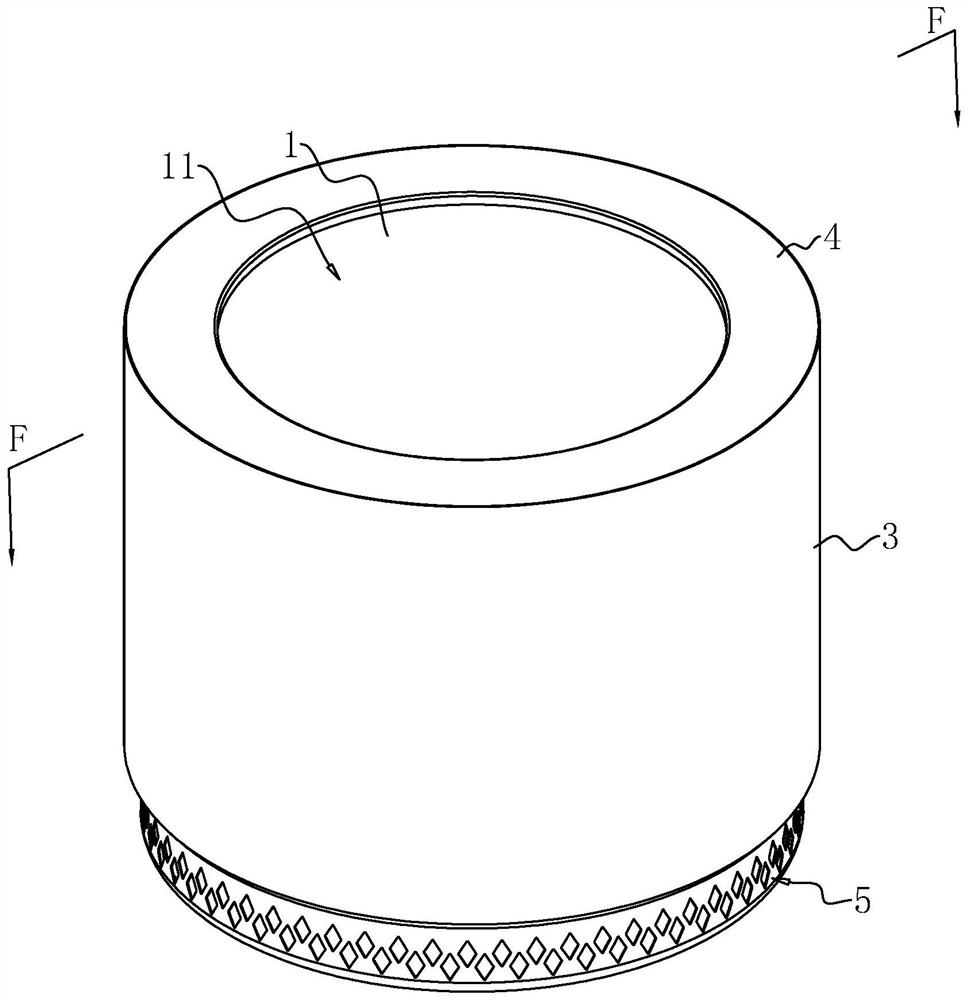

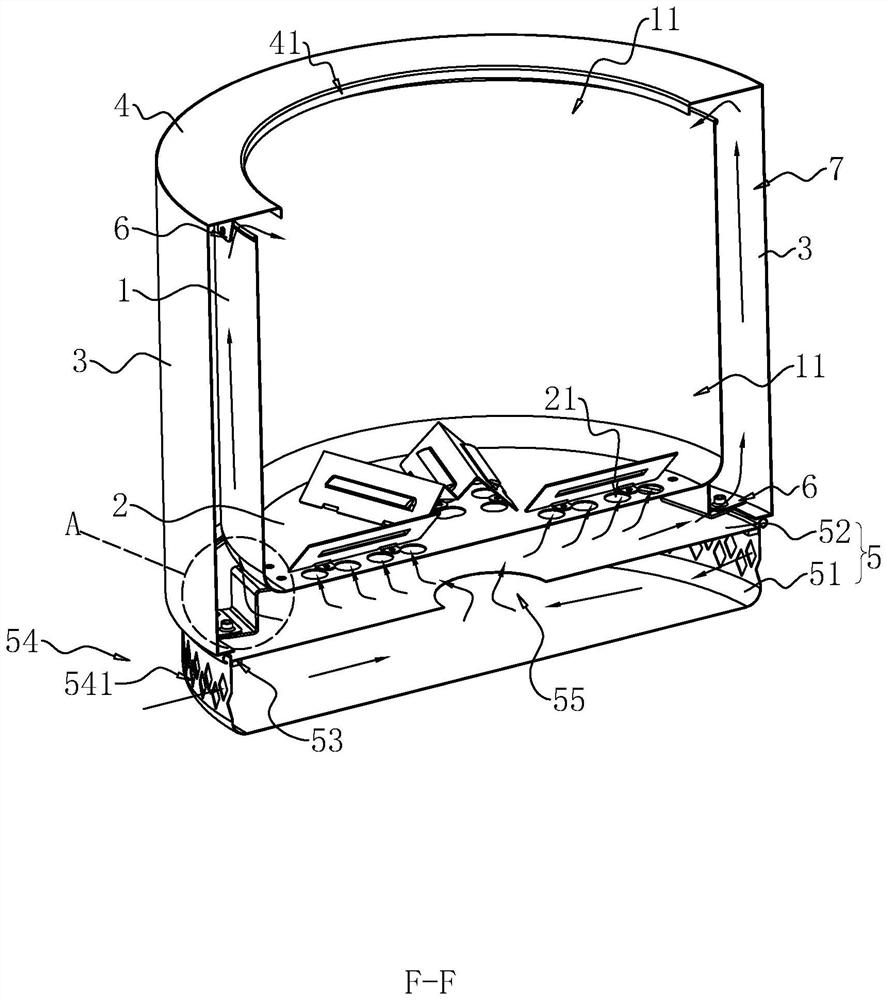

[0037] refer to figure 1 and figure 2 , the smokeless heating furnace includes a furnace body 1, a heat insulation board 2, a thermal insulation pipe 3, an installation ring seat 4 and an air intake assembly 5; wherein:

[0038] The heat shield 2 is fixedly connected to the bottom end surface of the furnace body 1, and a number of gas supply channels 21 are opened through it, and the number of gas supply channels 21 are distributed equidistantly around the center line of the furnace body 1; the installation ring seat 4 is fixedly connected On the end surface of the top of the furnace body 1 , there is a feeding port 41 penetrating through it; the center line of the feeding port 41 and the center line of the furnace body 1 are collinearly arranged.

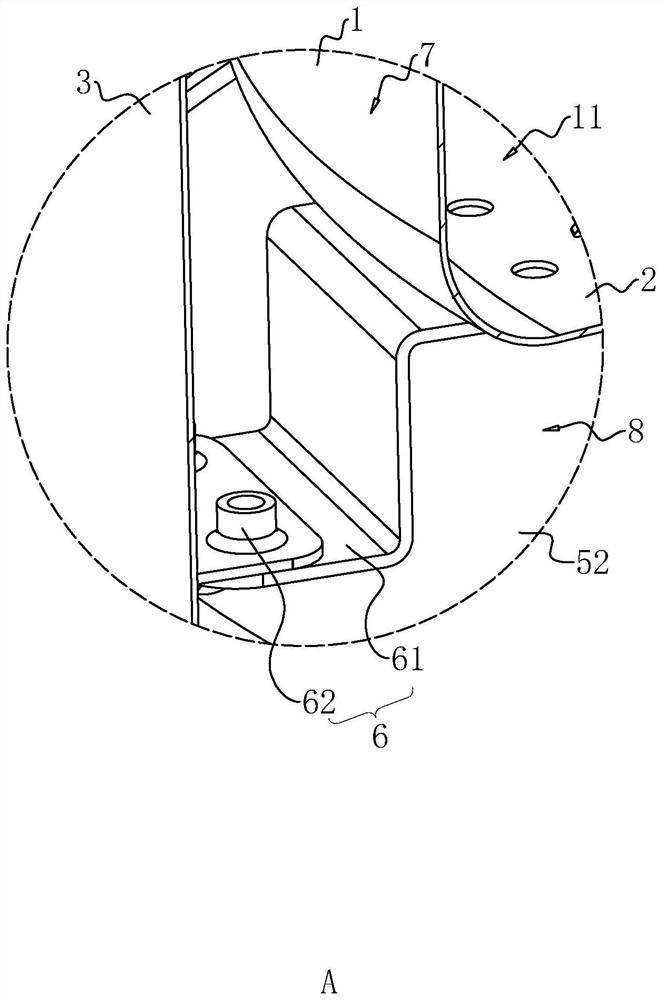

[0039]The insulation pipe 3 is sleeved on the outer edge of the furnace body 1. There are two sets of butt fittings 6 connected by bolts on the outer edge of the furnace body 1. The other end of 6 is connected with the air intak...

Embodiment 2

[0054] refer to Figure 5 , The difference between this embodiment and Embodiment 1 is that the inner wall of the feeding port 41 is concavely provided with a circumferentially extending annular slot 42; the annular slot 42 is elastically connected with a grill 43.

[0055] The implementation principle of embodiment 2 is: the barbecue rack 43 can be clamped in the annular slot 42, on the one hand, the stability of the clamping connection between the barbecue rack 43 and the installation ring seat 4 can be improved, and on the other hand, the practicability of the heating stove can be improved.

Embodiment 3

[0057] refer to Figure 6 The difference between this embodiment and Embodiment 2 is that a hollow metal base 44 is elastically clamped in the annular slot 42, and the inner wall diameter of the end of the metal base 44 away from the mounting ring seat 4 is smaller than the inner wall diameter of the other end; The section along the vertical direction is arranged in an isosceles trapezoidal shape.

[0058] The outer wall of the metal base 44 is penetratingly provided with a plurality of round holes 45 , and the plurality of round holes 45 are equidistantly distributed vertically and horizontally on the outer wall of the metal base 44 .

[0059] The implementation principle of embodiment 3 is: install the metal base 44, on the one hand, it can reduce the heat dissipated by the feeding port 41, prolong the combustion stroke of the combustion chamber 11, thereby reducing the smoke outside the furnace body 1, and on the other hand, it is convenient for users to adopt The stove is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com