Device capable of continuously using fluorescent film sensor and application thereof

A thin-film sensor and fluorescent technology, applied in the field of fluorescent sensors, can solve the problems of decreased sensitivity, decreased sensitivity, and reduced sensitivity, and achieve the effects of avoiding lifespan decline, improving detection lifespan, and solving cross-contamination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

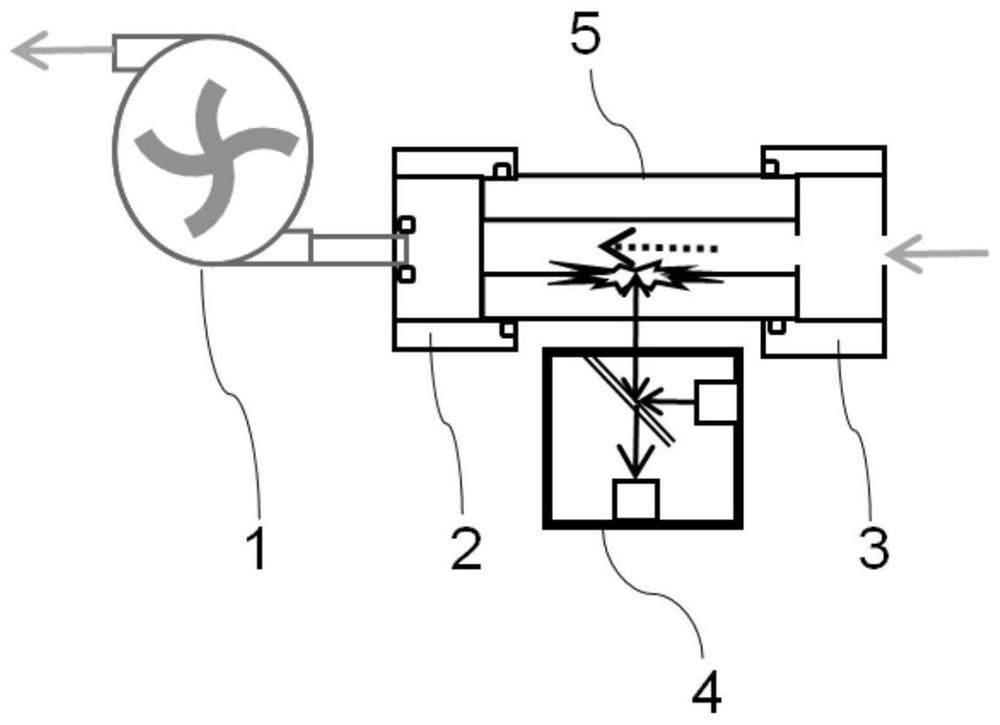

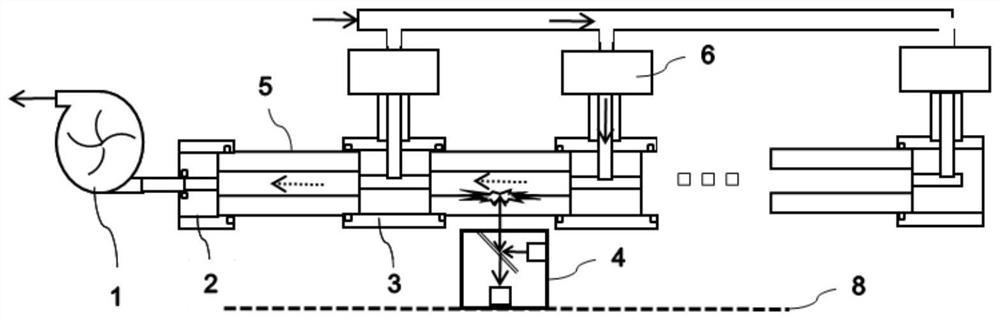

[0031] Such as figure 2 As shown, the present invention provides a device that can continuously use fluorescent thin film sensors, and adopts the method of connecting multiple fluorescent thin film capillaries 5 in series to achieve the purpose of greatly reducing the replacement frequency of sensitive components. The detection path consists of a fluid pump 1, a thin fluorescent thin tube 5, a communication device 3 for a three-way fluid passage, a solenoid valve 6 and a universal inlet. When the sensitivity of a fluorescent thin tube 5 close to the fluid pump 1 decreases and needs to be abandoned, the fluorescent detection unit 4 moves to the next fluorescent thin tube 5 on the electronically controlled slide rail 8, corresponding to the position of the fluorescent thin tube 5. The solenoid valve 6 is opened, and the rest of the solenoid valves 6 are closed, so that the fluid only enters the new thin tube of fluorescent film 5 through the solenoid valve 6 . In addition, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com