Mechanical clamp for clamping optical lens

An optical lens and mechanical technology, applied in the field of optical applications, can solve the problems of low stability and high cost, and achieve the effect of high stability, low cost and uniform strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

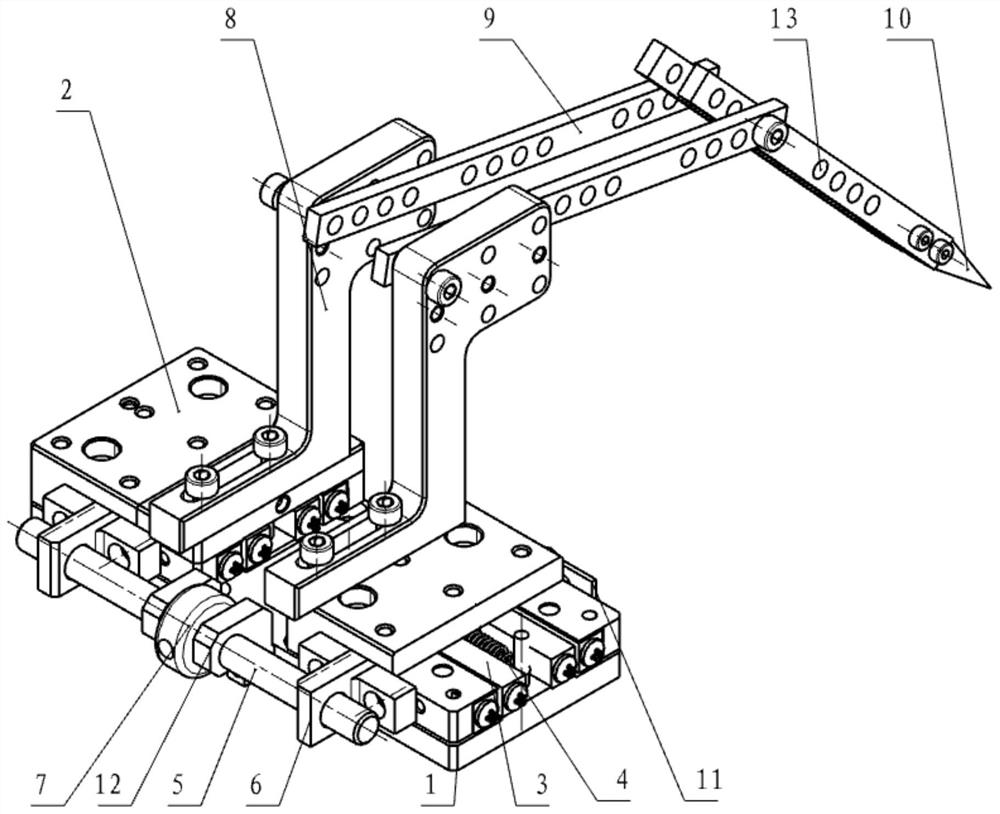

[0027] In order to enable those skilled in the art to better understand the solutions of the present application, the technical solutions of the embodiments of the present application will be clearly and completely described below in conjunction with the drawings in the embodiments of the present application.

[0028] A mechanical fixture for clamping optical lenses, including a base 1, two moving components, two clamping components, a lead screw component and a clamping head 10; after the two moving components are respectively installed with a clamping component, the whole Installed on the base 1, at the same time, the two moving components are driven by the screw component to perform reverse synchronous movement on the base 1, thereby adjusting the distance between the two clamping components, so that it is installed between the two clamping components The clamping head 10 between clamps or releases the optical lens.

[0029] Optionally, the clamping head 10 is made of plast...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com