Clamping and sealing method for ultrahigh-vacuum-degree exhaust equipment of hemispherical resonator gyroscope

A hemispherical resonant gyro, ultra-high vacuum technology, applied in shearing machine equipment, metal processing equipment, pipe shearing devices, etc., can solve problems such as high pressure, reduce production efficiency, affect device production work, etc., achieve consistent position, and improve work. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

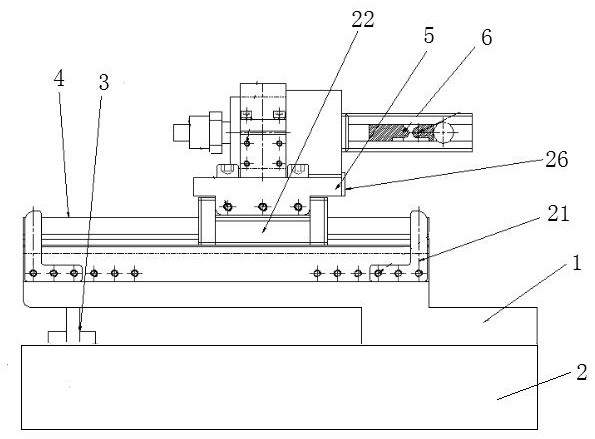

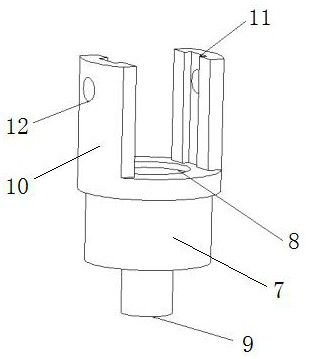

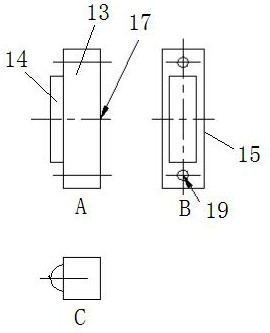

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0024] The hemispherical resonant gyro ultra-high vacuum exhaust equipment clamping method of the present invention, the steps are as follows,

[0025] 1) First obtain the clamping device for the ultra-high vacuum exhaust equipment of the hemispherical resonator gyroscope;

[0026] 2) Then the exhaust pipe of the hemispherical resonant gyro ultra-high vacuum exhaust equipment is clamped for the first time by the clamping device. At the same time of clamping, the vacuum equipment is used to suck the gas released when the exhaust pipe is deformed ;When clamping for the first time, do not pinch off the exhaust pipe;

[0027] 3) When the vacuum degree display of the vacuum equipment returns to the normal display, then follow step 2) to perform the next clamping of the exhaust pipe on the basis of the previous clamping;

[0028] 4) Repea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com