3D visual guidance groove cutting method, device, equipment and system and storage medium

A vision-guided, 3D technology, applied in the field of devices, 3D vision-guided beveling methods, equipment, systems and storage media, can solve problems such as inability to adapt to different types of workpieces, and inability to avoid the six-axis over-limit problem of robots, to achieve The effect of improving production safety, coherent cutting operation and reasonable rotation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

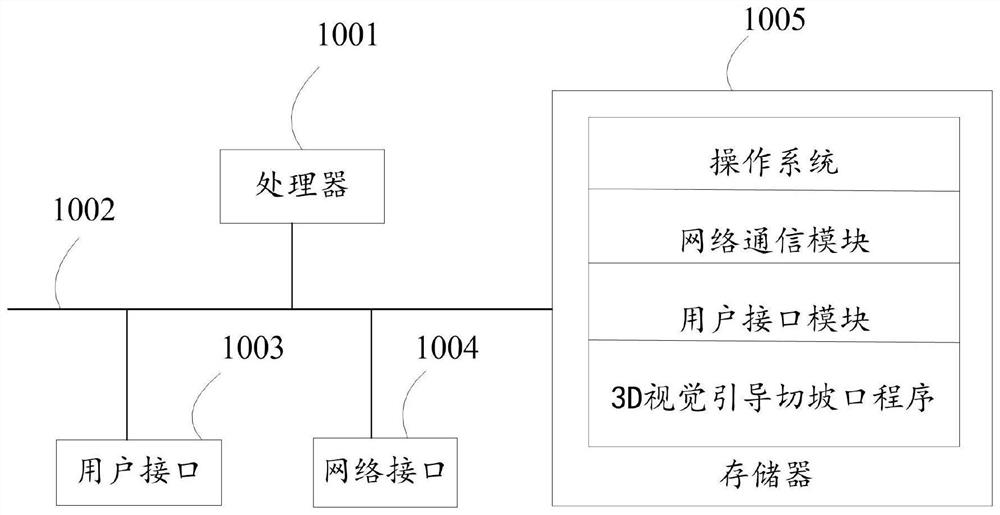

[0050] refer to figure 1 , figure 1 It is a structural schematic diagram of the 3D vision-guided beveling equipment of the hardware operating environment involved in the solution of the embodiment of the present invention.

[0051] like figure 1 As shown, the 3D vision-guided beveling device may include: a processor 1001 , such as a central processing unit (Central Processing Unit, CPU), a communication bus 1002 , a user interface 1003 , a network interface 1004 , and a memory 1005 . Wherein, the communication bus 1002 is used to realize connection and communication between these components. The user interface 1003 may include a display screen (Display). The optional user interface 1003 may also include a standard wired interface and a wireless interface. The wired interface of the user interface 1003 may be a USB ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap