Climbing robot

A technology of robots and joints, applied in the field of climbing robots, can solve problems such as difficulty in maintenance work, threats to the life safety of electric workers, etc., and achieve better performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The principles and features of the present invention will be described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

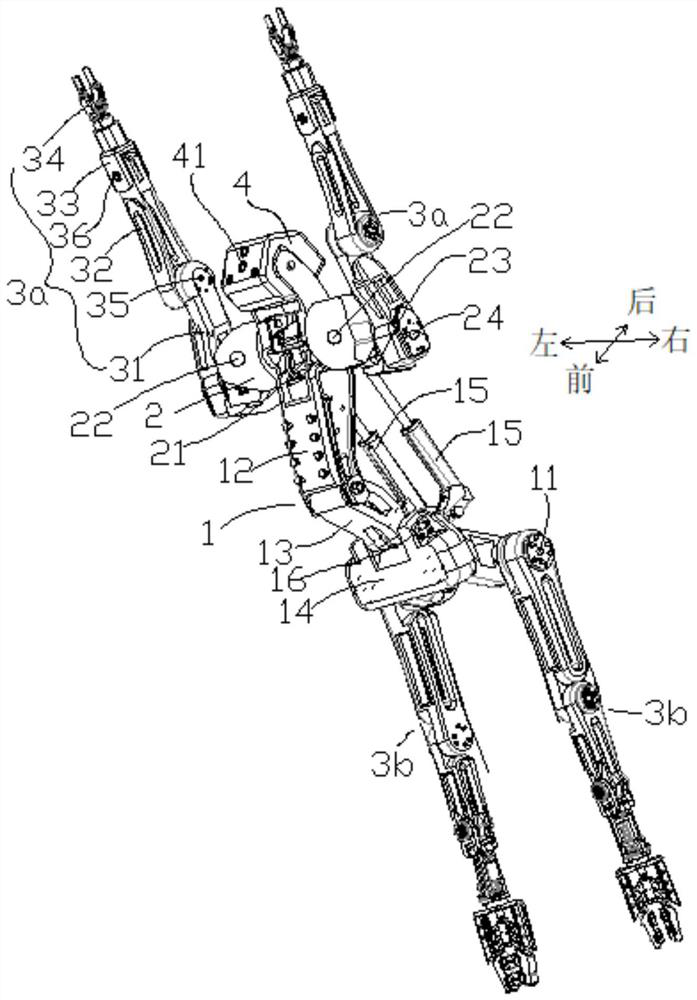

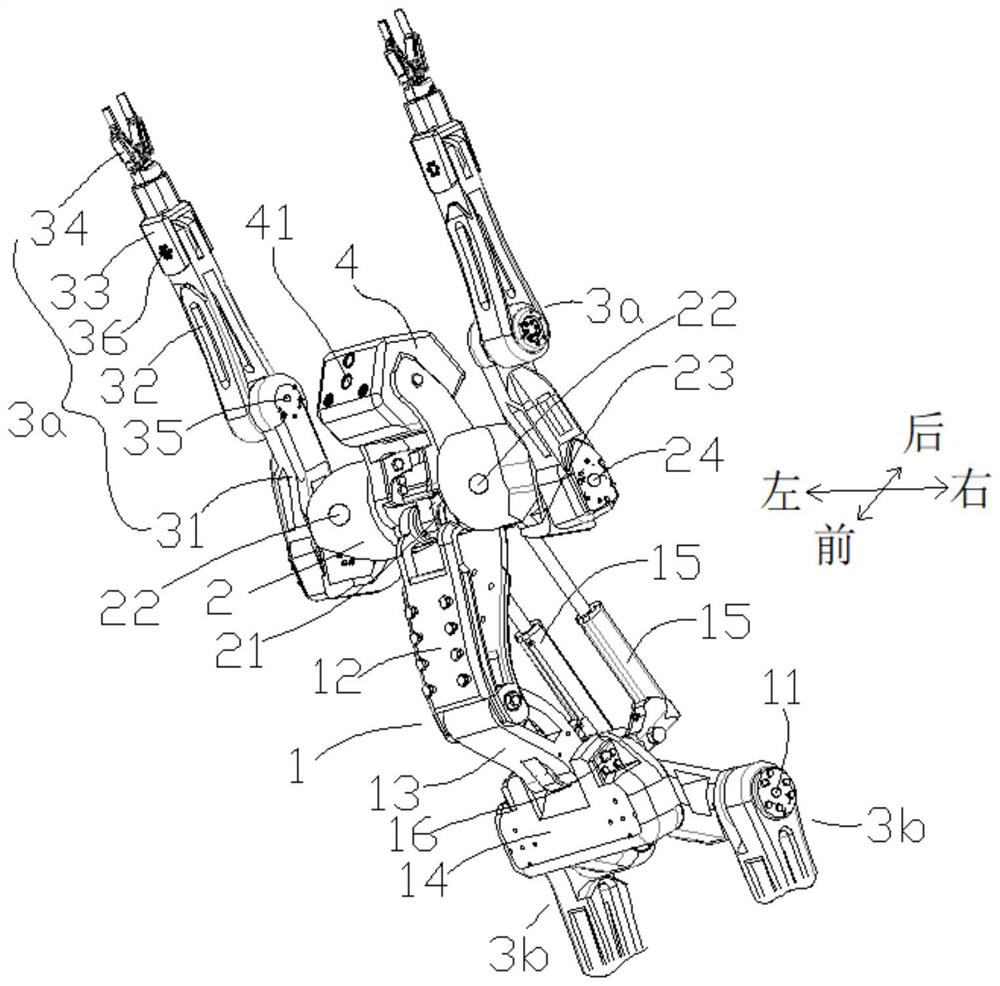

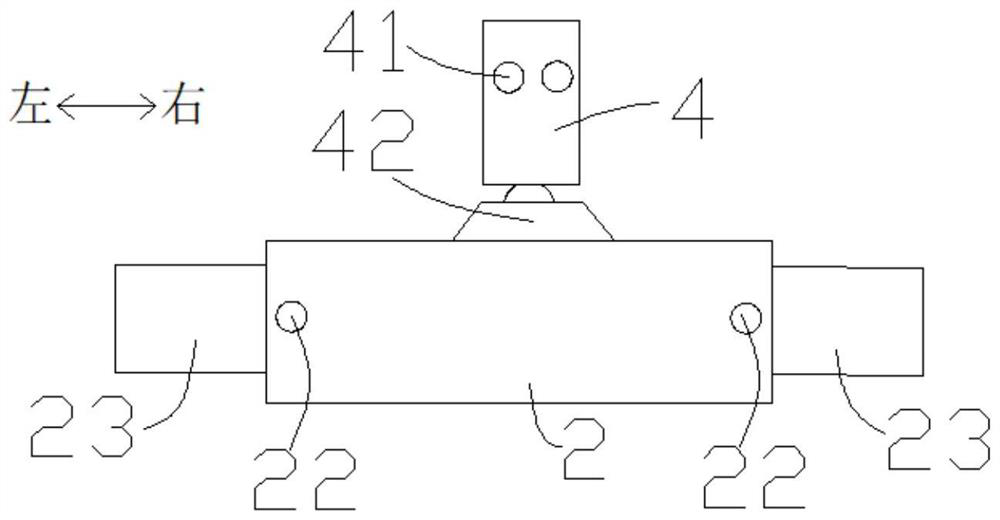

[0021] Such as Figure 1-Figure 3 As shown, the present embodiment provides a climbing robot, including a body 1, a shoulder 2 and four limbs, the four limbs include two upper limbs 3a and two lower limbs 3b, and the body 1 is vertically vertical along the left-right direction. The shoulder 2 is arranged above the body 1 along the left and right direction, and the middle part of the lower end of the shoulder 2 is rotationally connected with the middle part of the upper end of the body 1 through the first joint motor 21, and the first joint The motor 21 is used to drive the shoulder 2 to swing back and forth relative to the body 1, and a shoulder joint 23 is installed on the left and right sides of the shoulder 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com