Hydrolysis acidification reaction tank for waste treatment

A technology of hydrolytic acidification and reaction tank, which is applied in the direction of anaerobic digestion treatment, etc., can solve the problem that the water inlet cannot be effectively operated, and achieve the effects of easy agitation and sludge discharge, fast drainage speed, and avoiding blockage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

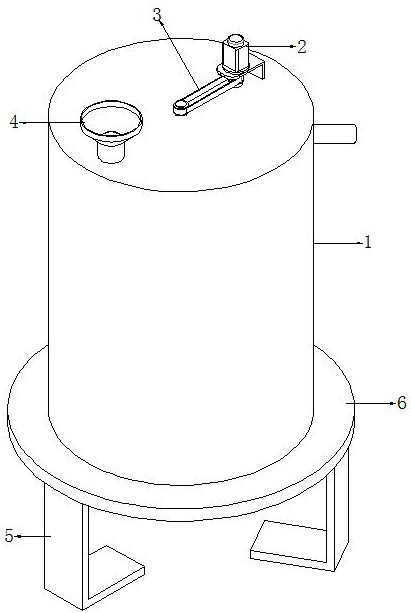

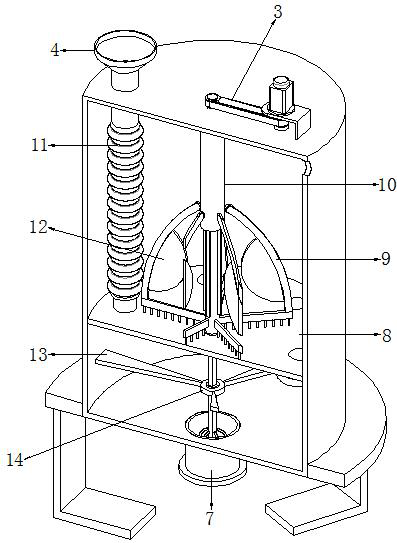

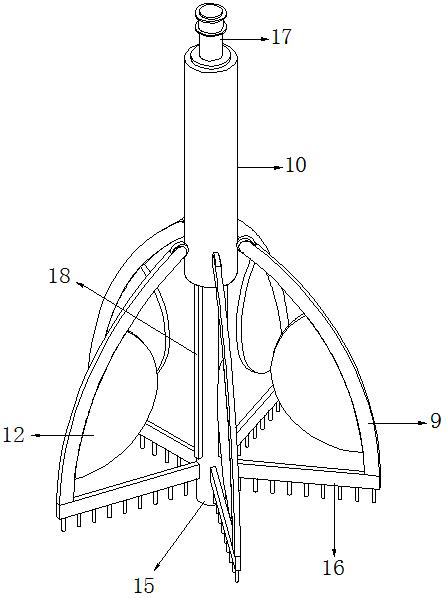

[0031] refer to Figure 1-6 , a hydrolysis and acidification reaction tank for waste sewage treatment, including a tank body 1, the middle position of the top of the tank body 1 is connected with a drum 10 through a bearing, and the top of the drum 10 is provided with a driving mechanism, and the inner wall of the drum 10 A fixed rod 15 is plugged in, and a limit structure is arranged between the outer wall of the fixed rod 15 and the inner wall of the drum 10. The bottom of the outer wall of the fixed rod 15 is connected with a water seepage net 8 through a bearing, and the peripheral outer wall of the water seepage net 8 is connected to the pool body 1 The outer wall of the fixed rod 15 close to the top of the seepage net 8 is provided with a mixed structure, and the top of the seepage net 8 is provided with equidistant circular holes distributed in a ring, and the inner wall of one of the circular holes is welded with a liquid guide Pipe 20, the top side of the tank body 1 ...

Embodiment 2

[0040] refer to Figure 7 , a hydrolysis acidification reaction tank for waste sewage treatment. Compared with Example 1, the corner of the bottom inner wall of the pool body 1 is connected with an annular material guide seat 25 by bolts, and the inner wall of the annular material guide seat 25 Set to bevel structure.

[0041] Working principle: When in use, the user quickly discharges the silt and other impurities at the bottom of the pool body 1 through the annular material guide seat 25, so as to avoid sludge and other impurities remaining at the bottom corner of the pool body 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com