Preparation method of broadband high-transmittance Al2O3/MgF2 double-layer antireflection film

An anti-reflection film and broadband technology, applied in coating, sputtering coating, metal material coating process, etc., can solve the problems affecting the optical performance of double-layer anti-reflection film, high refractive index of film, etc., and achieve average transmittance Improvement, light transmission performance improvement, and the effect of increasing transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

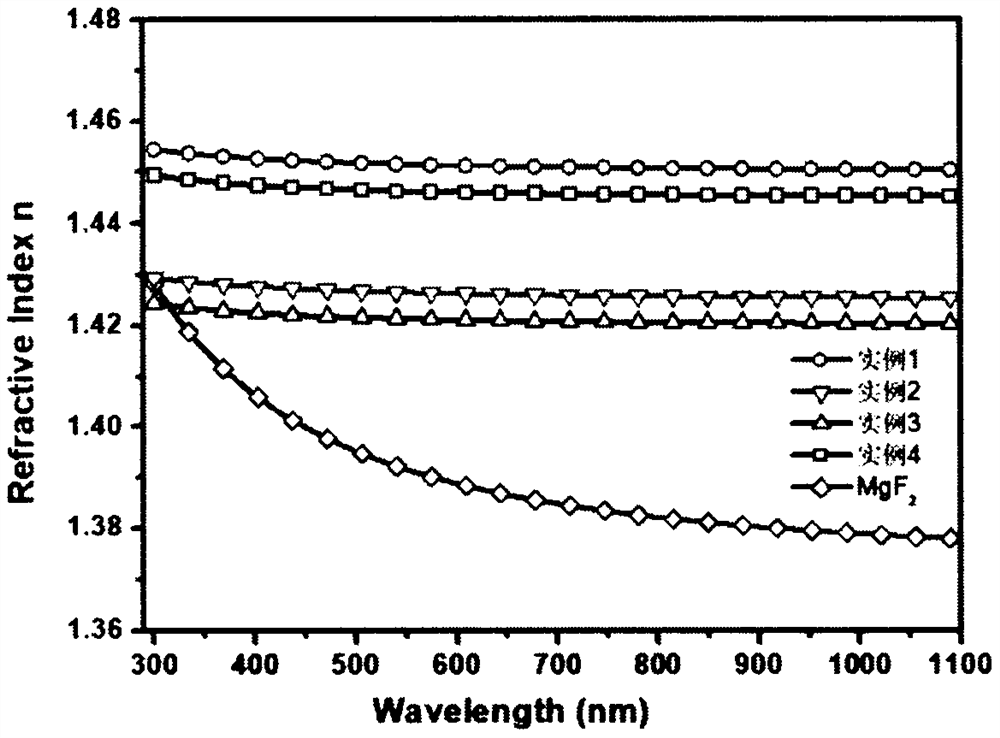

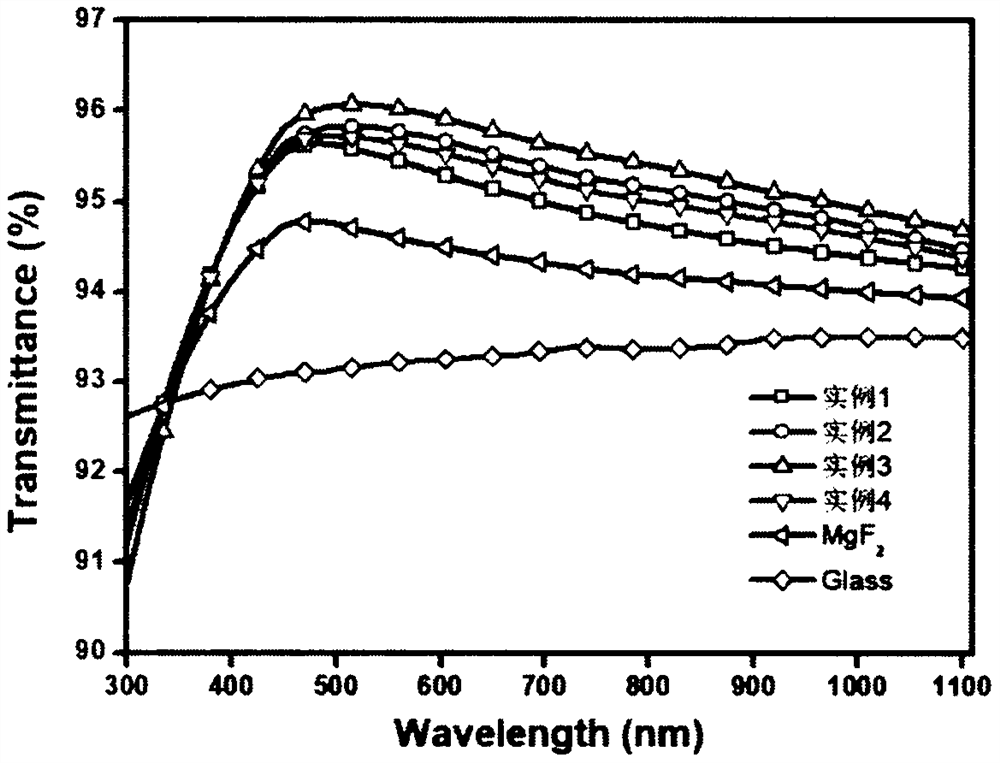

Examples

Embodiment 1

[0016] Take Al 2 o 3 Preparation of broadband and high transmission double-layer Al by magnetron sputtering method for the target 2 o 3 / MgF 2 A thin film method comprising the steps of:

[0017] (1)O 2 Gas doping amount setting: high-purity O 2 (99.999%) as a reaction gas, with high-purity Ar 2 (99.999%) as the working gas, the total gas flow is set to 80sccm during sputtering, the O 2 / Ar 2 The gas flow ratios were set to 5% to allow the gases to mix well in the reaction chamber.

[0018] (2) Sputtering Al 2 o 3 Parameter setting: the sputtering working pressure is set to 0.5Pa; the sputtering power is set to 50W.

[0019] (3) Sputtering MgF 2 Parameter setting: with high-purity Ar 2 (99.999%) as working gas, high purity SF 6 (99.999%) as the reaction gas, the total gas flow rate during sputtering is set to 60 sccm, the SF 6 / Ar 2 The gas flow ratio is set to 0.5%, the sputtering working pressure is 0.1Pa; the sputtering power is set to 30W.

Embodiment 2

[0021] Take Al 2 o 3 Preparation of broadband and high transmission double-layer Al by magnetron sputtering method for the target 2 o 3 / MgF 2 A thin film method comprising the steps of:

[0022] (1)O 2 Gas doping amount setting: high-purity O 2 (99.999%) as a reaction gas, with high-purity Ar 2 (99.999%) as the working gas, the total gas flow is set to 80sccm, O 2 / Ar 2 The gas flow ratios were set to 10% so that the gases were well mixed in the reaction chamber.

[0023] (2) Sputtering Al 2 o 3 Parameter setting: the sputtering working pressure is set to 1.0Pa; the sputtering power is set to 115W.

[0024] (3) Sputtering MgF 2 Parameter setting: with high-purity Ar 2 (99.999%) as working gas, high purity SF 6(99.999%) as the reaction gas, the total gas flow rate during sputtering is set to 60 sccm, the SF 6 / Ar 2 The gas flow ratio is set to 1%, the sputtering working pressure is 0.5Pa; the sputtering power is set to 60W.

Embodiment 3

[0026] Take Al 2 o 3 Preparation of broadband and high transmission double-layer Al by magnetron sputtering method for the target 2 o 3 / MgF 2 A thin film method comprising the steps of:

[0027] (1)O 2 Gas doping amount setting: high-purity O 2 (99.999%) as a reaction gas, with high-purity Ar 2 (99.999%) as the working gas, the total gas flow is set to 80sccm, O 2 / Ar 2 The gas flow ratios were set to 15% to allow the gases to mix well in the reaction chamber.

[0028] (2) Sputtering Al 2 o 3 Parameter setting: the sputtering working pressure is set to 1.5Pa; the sputtering power is set to 150W.

[0029] (3) Sputtering MgF 2 Parameter setting: with high-purity Ar 2 (99.999%) as working gas, high purity SF 6 (99.999%) as the reaction gas, the total gas flow rate during sputtering is set to 60 sccm, the SF 6 / Ar 2 The gas flow ratio is set to 2%, the sputtering working pressure is 1.5Pa; the sputtering power is set to 120W.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com