Plating solution full-automatic analysis method and computer readable storage medium

A fully automated and analytical method technology, applied in the direction of material analysis, material analysis by electromagnetic means, material electrochemical variables, etc., can solve problems such as difficult to realize automatic analysis, and achieve the effect of ensuring the accuracy and correctness of the analysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

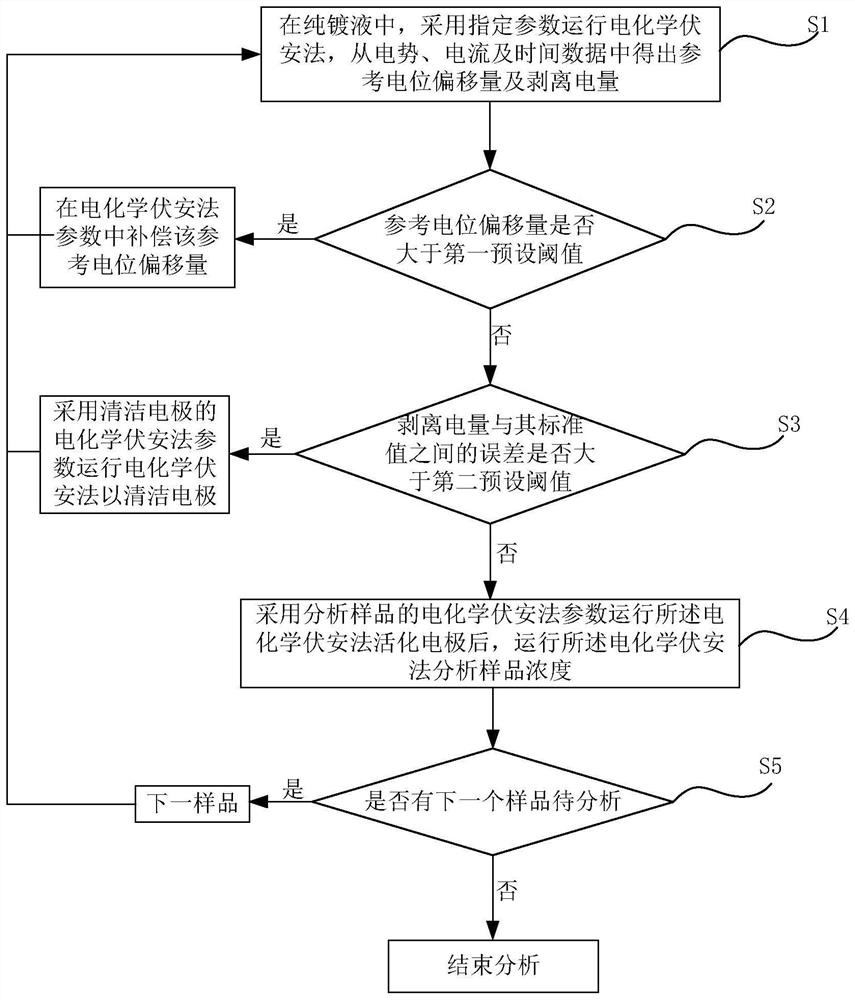

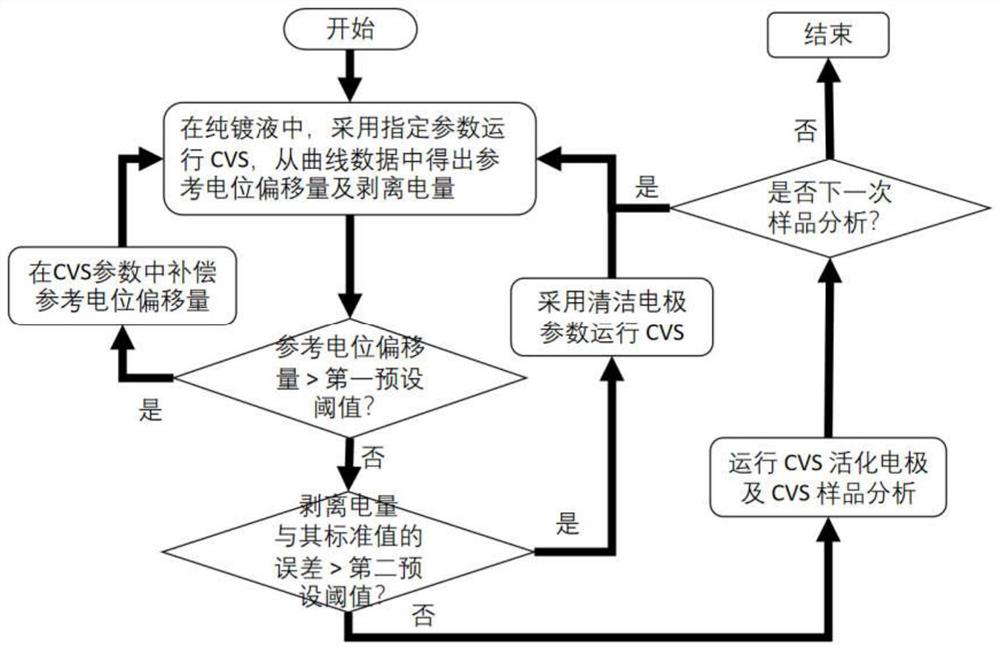

[0024] In order to make the technical solution of the present invention more comprehensible, the following examples are given together with the accompanying drawings to further illustrate the present invention. The specific embodiment of the present invention proposes a fully automatic analysis method for plating solution, aiming at realizing continuous automatic analysis of additives in the plating solution, figure 1 is a flowchart of the method. Please refer to figure 1 , the method includes the following steps S1-S5:

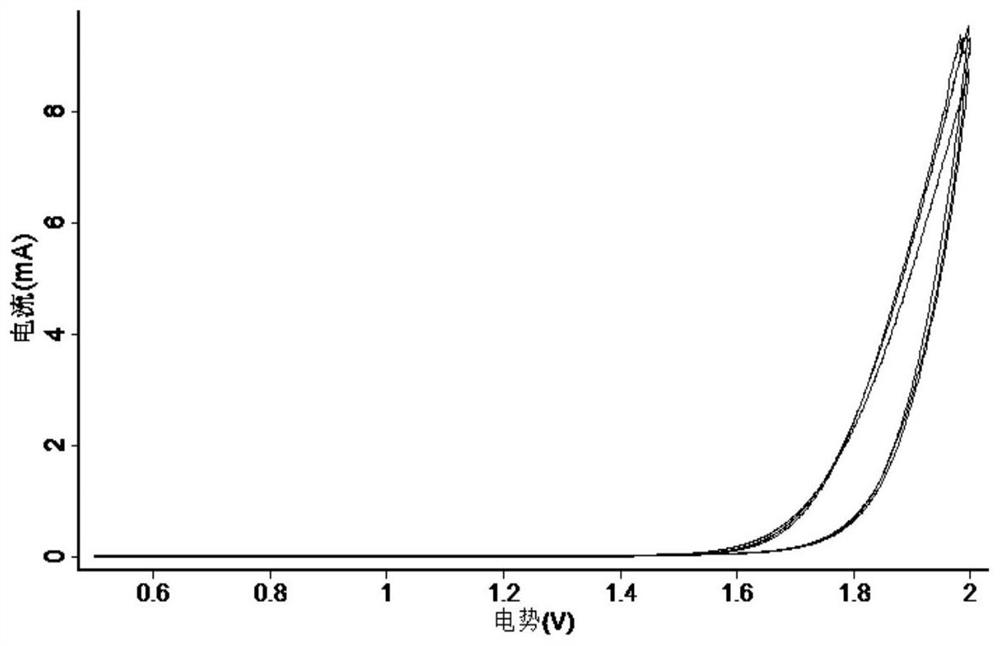

[0025] Step S1, in the pure plating solution, run electrochemical voltammetry with specified parameters, and obtain the reference potential offset and the stripping electric quantity from the potential, current and time data. It should be understood that the plating solution here may be copper electroplating solution, zinc electroplating solution, tin electroplating solution or nickel electroplating solution, etc., and is not limited thereto. The electroch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com