Processing method of anti-interference 5G base station signal amplifier printed circuit board

A signal amplifier and printed circuit board technology, applied in multi-layer circuit manufacturing and other directions, can solve problems such as large alignment difficulty, removal, and core board displacement, etc., to ensure stacking accuracy, reduce stacking difficulty, Guaranteed effect of lamination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

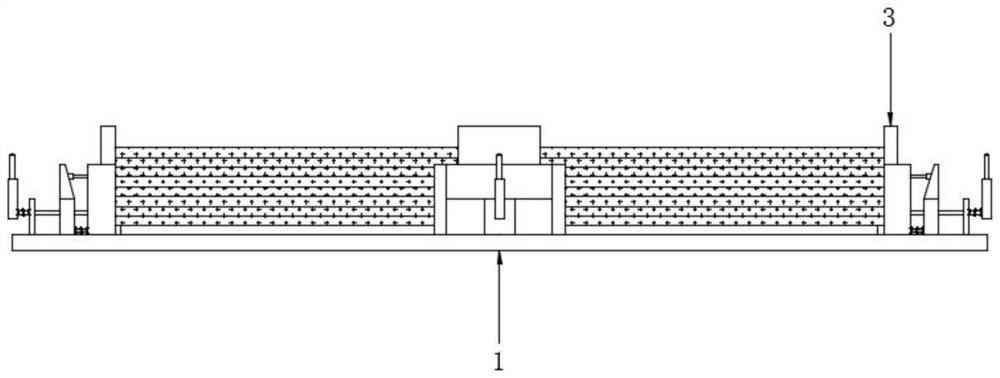

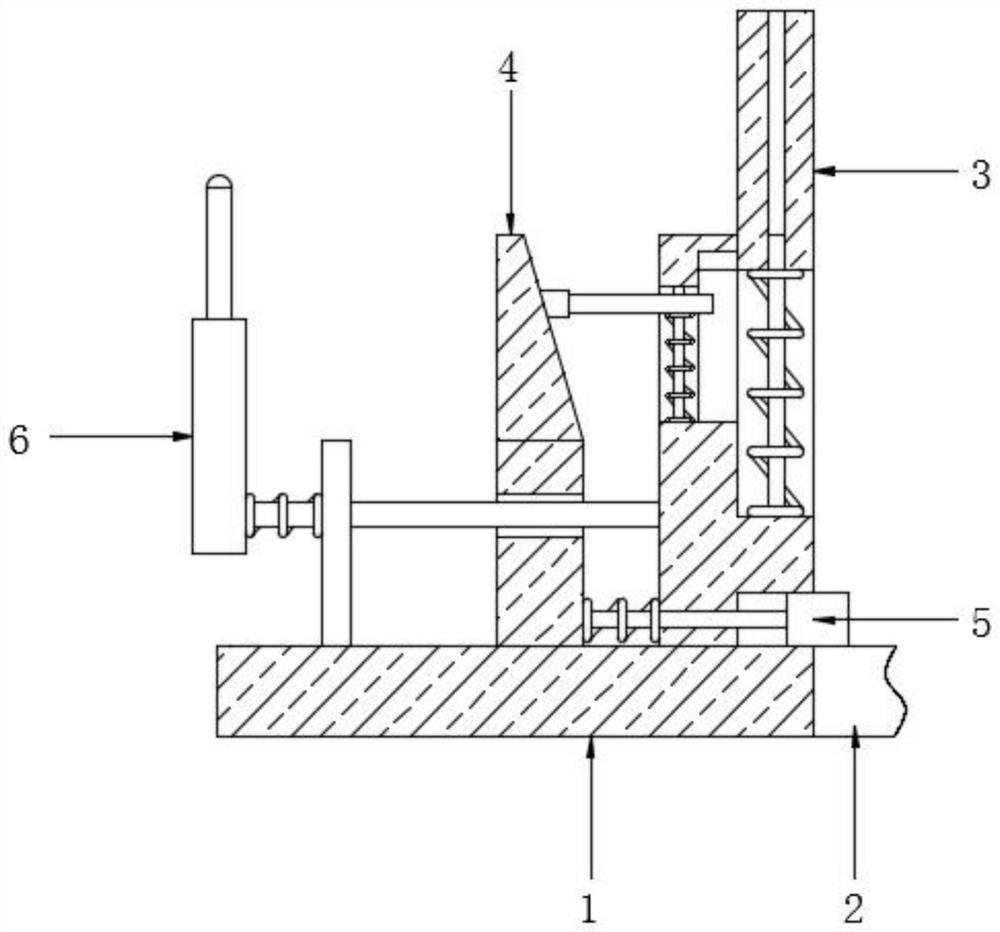

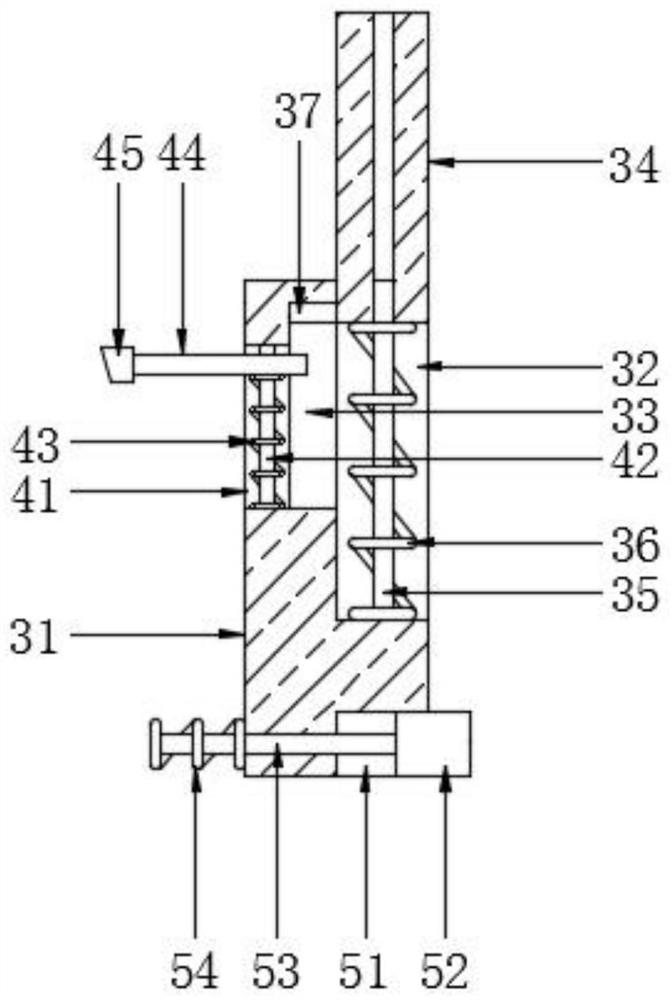

[0036] The present invention provides such Figure 1-4 A processing method of an anti-jamming 5G base station signal amplifier printed circuit board is shown, the processing method is realized by stacking the rectifying seat, and the stacking rectifying seat includes a base plate 1, and the center of the top of the base plate 1 is provided with a second A through groove 2 and the four sides of the top of the base plate 1 are provided with an elevating positioning mechanism 3, the outside of the elevating positioning mechanism 3 is provided with a trigger driving mechanism 4 and the bottom of the elevating positioning mechanism 3 is provided with a lower limit mechanism 5, so When the inner positioning plate 34 in the lifting positioning mechanism 3 descends along the lifting chute 32 in the lifting positioning mechanism 3, it drives the limit slider 37 in the lifting positioning mechanism 3 to the lifting pressure plate in the trigger driving mechanism 4. 44 is pressed down, s...

Embodiment 2

[0044] Described processing method specifically comprises the following steps:

[0045] S1. Use TG170 material core board to make L1 and L2 layers, use ROGERS material core board to make L3 to L(N-2) layers, and use TG170 material core board to make L(N-1) and LN layers;

[0046] S2. Perform pre-process treatment on layers L3 to L(N-2), including cutting, baking plate, inner layer wet film, inner layer etching and internal inspection;

[0047] S3. Stack L3 to L(N-2) layers, and place them on the inside of the four lifting positioning mechanisms 3 on the top of the base plate 1. At this time, the four limit blocks 52 block the bottom L3. An outer positioning plate 31 cooperates with four inner positioning plates 34 to position the stacked L3 to L(N-2) layers;

[0048] S4. Place the stacking and straightening seat carrying layers L3 to L(N-2) on the fixed heat platen inside the laminator, and then start the laminator. Pressing plate begins to descend, and along with the contin...

Embodiment 3

[0054] The difference from the above-mentioned embodiment is that, if figure 2 and Figure 5 As shown, the stacking orthopedic seat also includes an adjustment mechanism 6, the adjustment mechanism 6 is located outside the trigger drive mechanism 4, and the adjustment mechanism 6 includes a mounting plate 61, a draw bar 62, a fourth return spring 63, a handle 64, The fifth return spring 65 and the extension rod 66 .

[0055] More specifically, the mounting plate 61 is fixedly arranged on the top of the base plate 1, the traction rod 62 runs through the mounting plate 61 in the horizontal direction and is slidably connected with the mounting plate 61, and the inner end of the traction rod 62 is connected to the outer positioning plate 31 Fixed connection and the outer end of the draw bar 62 is connected to the handle 64 through the bearing rotation, the fourth return spring 63 is sleeved on the outside of the draw bar 62, and one end thereof is fixedly connected to the mounti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com