Impurity removing machine for hulled whole grain particles and using method of impurity removing machine

A cleaning machine and whole grain technology, applied in chemical instruments and methods, separating solids from solids with air flow, solid separation, etc., can solve the problems of reducing grain, taking up more manpower, increasing the workload of grain reprocessing, etc. , to achieve the effects of increasing collection efficiency, improving removal efficiency, and saving manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

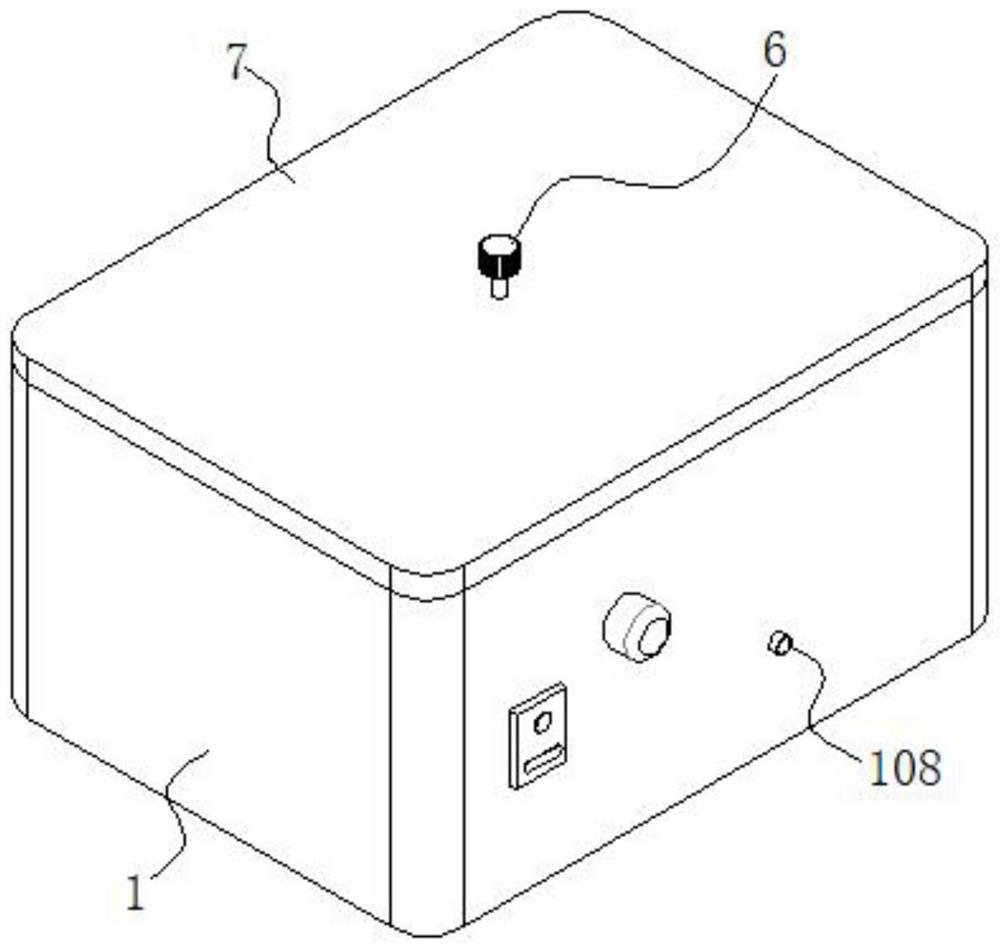

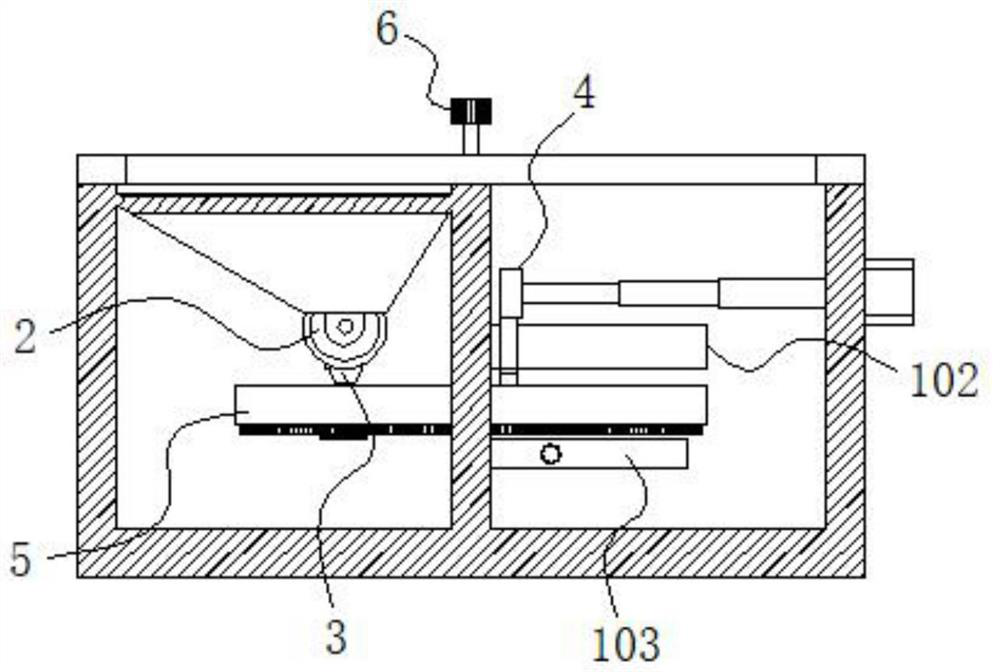

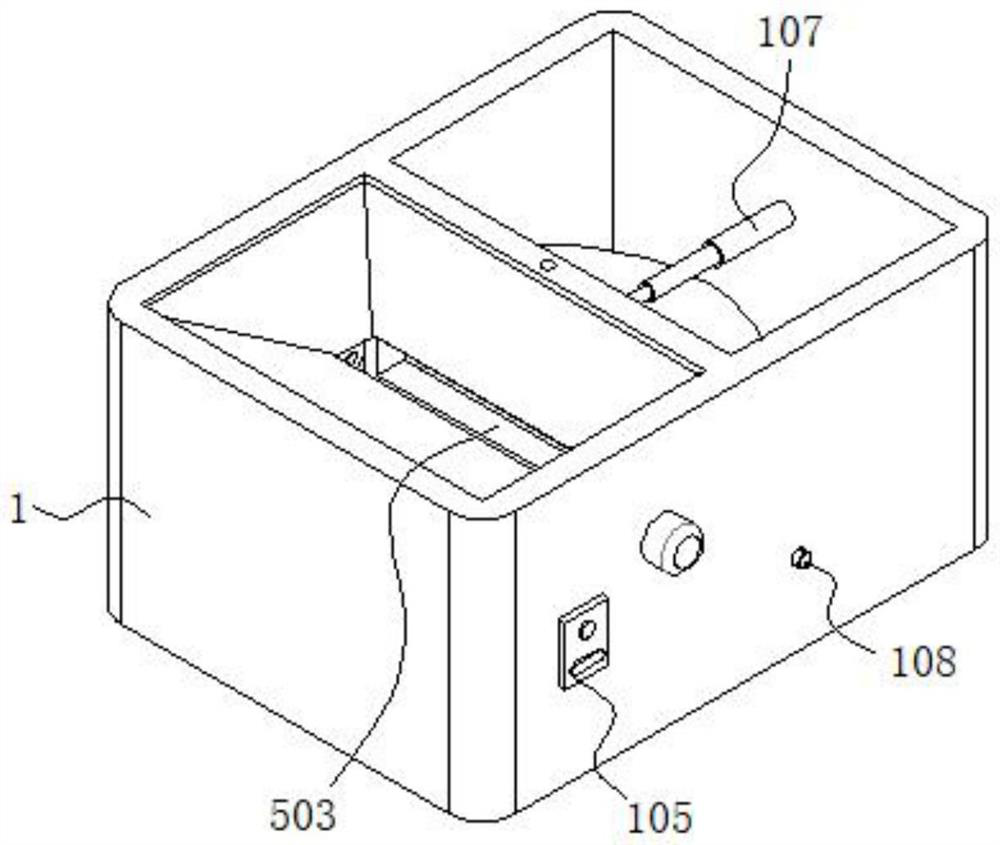

[0043] see Figure 1-12 , the present invention is a kind of impurity removal machine for the whole grain granule after shelling, comprises machine body 1, and the interior of machine body 1 is provided with feed chamber and collection chamber through the partition;

[0044] A storage hopper 101 is arranged inside the feeding chamber, and the shelled whole grain particles are added to the storage hopper 101 at one time before the impurity removal treatment. A material guide assembly 3 coaxial with the interval feed assembly 2 is fixed and the guide assembly 3 is sleeved outside the interval feed assembly 2; through the intermittent rotation of the interval feed assembly 2, the whole grain inside the storage hopper 101 The particles are intermittently discharged into the material guide assembly 3, and the whole grain particles flow downward through the material guide assembly 3;

[0045] Partition plate near the side wall of the collection chamber is provided with particle ads...

Embodiment 2

[0059] On the basis of embodiment 1, a kind of use method of the impurity removal machine for the whole grain particle after shelling, comprises the steps:

[0060] SS01 puts the husked whole grain particles in the storage hopper 101, uses the stepper motor 104 to drive the interval feeding assembly 2 to perform intermittent rotation, and intermittently transports the whole grain particles to the material guide assembly 3, and makes the whole grain The particles fall to the inside of the particle carrying tray 501;

[0061] SS02 uses the cooperation of the drive bevel wheel 204 on the interval feeding assembly 2 and the transmission bevel wheel 305 to drive the transmission gear 306 to rotate, and the cooperation between the transmission gear 306 and the tooth structure 502 realizes the particle carrying plate 501 and the interval feeder. The synchronous rotation of material assembly 2 utilizes scraper baffle plate 601 to pave the grain grain in the grain carrying disc 501;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com