Labor-saving device for bathroom production mold

A mold and hoisting technology, applied in the field of mold manufacturing, can solve the problem that the auxiliary grasping device cannot be invested on a large scale, and achieve the effect of reducing labor intensity and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to better understand the purpose, structure and function of the present invention, a labor-saving device for sanitary ware production molds of the present invention will be described in further detail below in conjunction with the accompanying drawings.

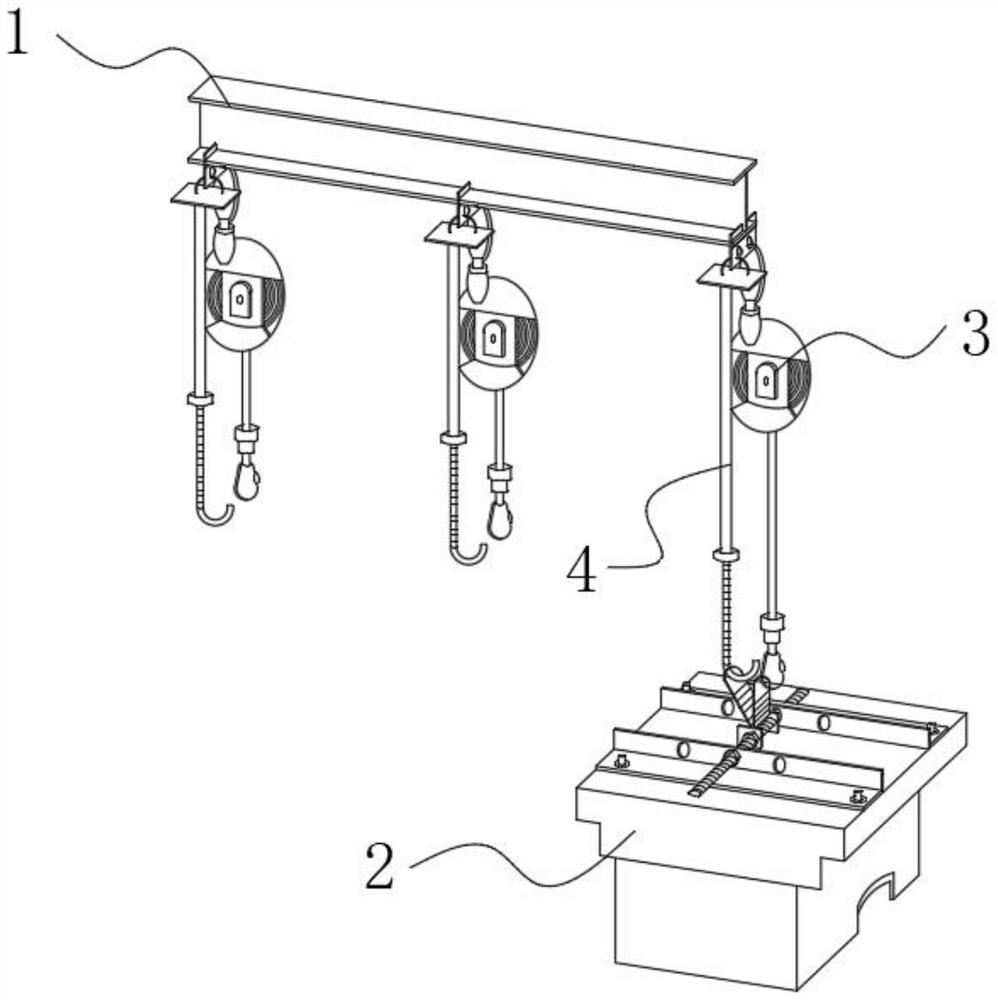

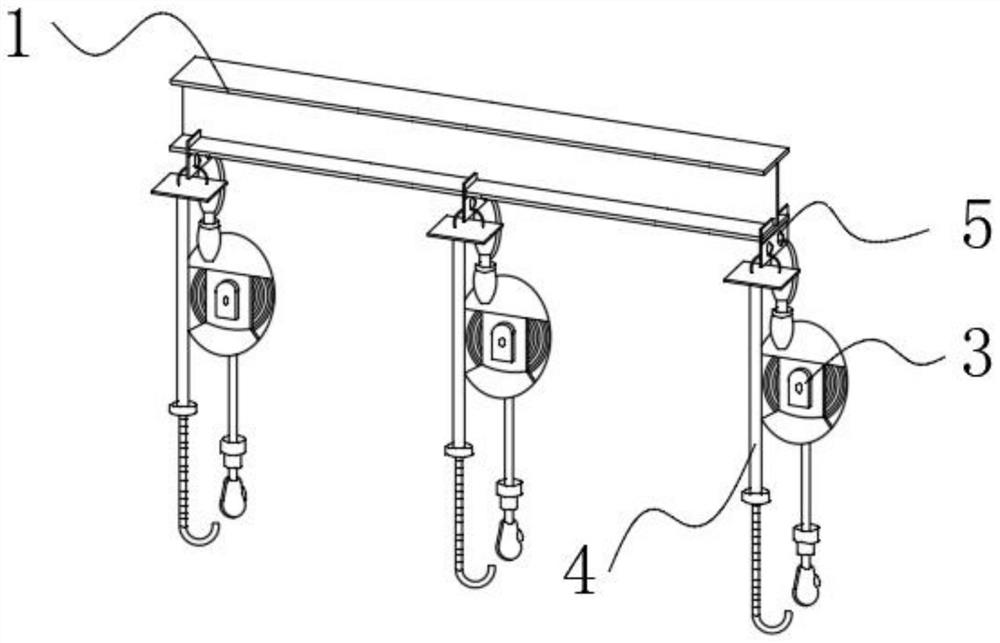

[0029] see Figure 1-7 , the present invention: a mold labor-saving device for sanitary ware production, comprising an I-shaped steel frame 1 and a mold 2, the I-shaped steel frame 1 is provided with a clip 5, and the clip 5 is respectively hoisted with a spring balancer 3 and a telescopic fixed 4, a fixed locking structure 6 is installed on the top of the mold 2, and one end of the spring balancer 3 and the telescopic fixer 4 are both socketed with the fixed locking structure 6;

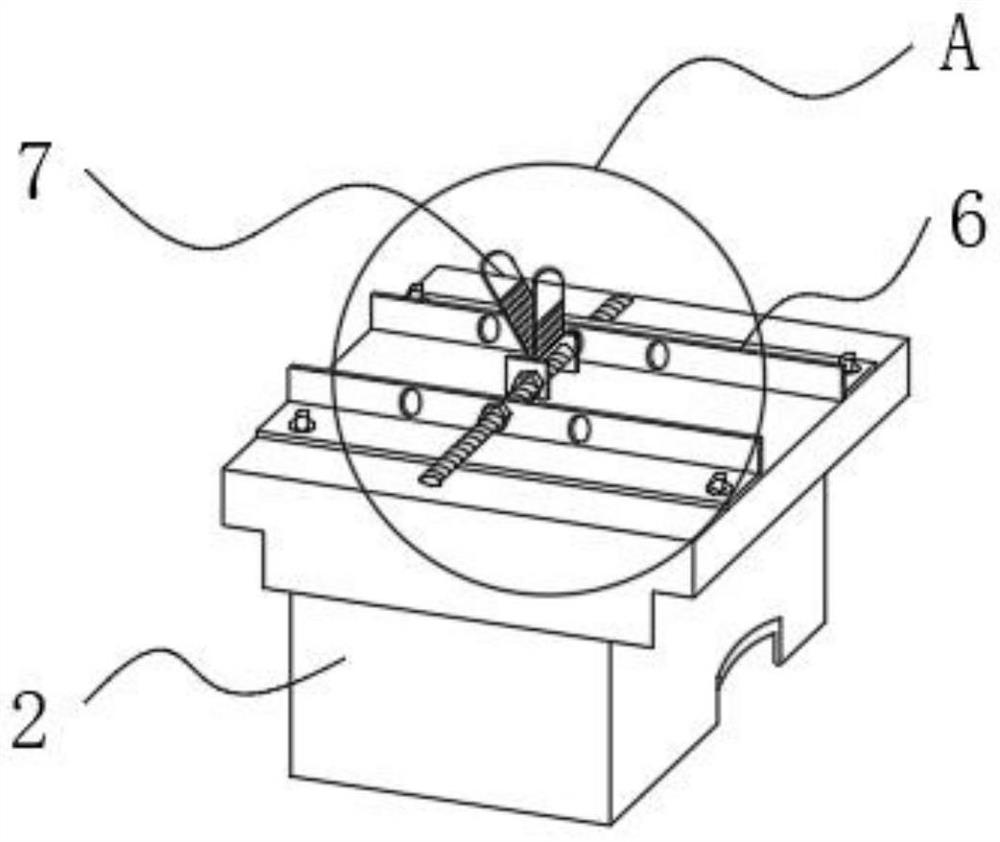

[0030] Wherein, the fixed locking structure 6 includes two sets of L-shaped plates 61 and threaded columns 62, the L-shaped plates 61 are fixed on the top panel of the mold 2 by bolts 64, and the two sets of L-shaped plates 61 are o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com