Equipment for feeding and discharging, press-fitting machine and method

A press-fitting machine and equipment technology, which is applied in the field of rail transit, can solve the problems that the production capacity of the equipment cannot meet the maintenance requirements, the low utilization rate of single-column press equipment, and the low efficiency of loading and unloading work, so as to reduce the burden of manual work and make the structure reasonable. , to ensure the effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

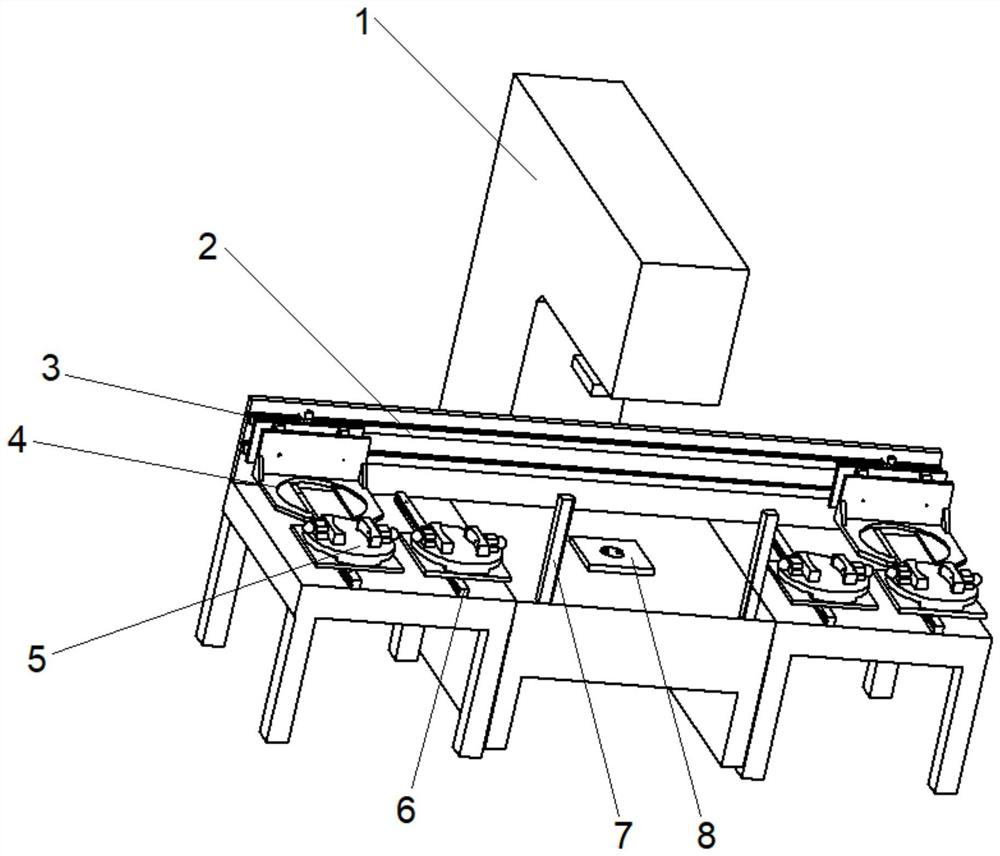

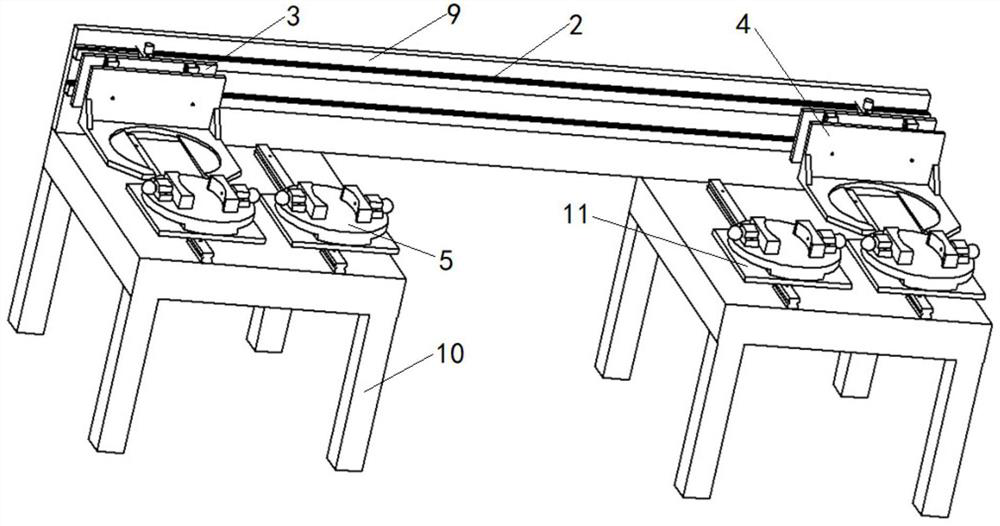

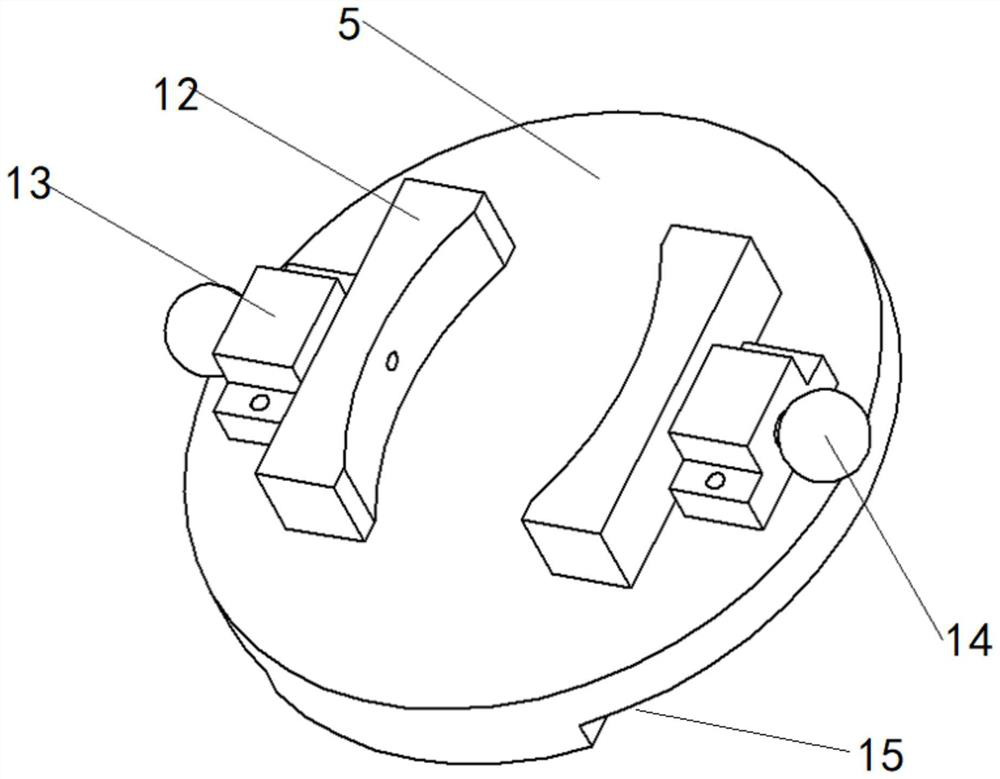

[0052] In a typical embodiment of the present invention, refer to figure 2 As shown, a device for loading and unloading includes a workbench 10, which supports a transfer mechanism, and the transfer mechanism includes an X-direction moving unit 2 and at least one Y-direction moving unit 6, and the Y-direction moving unit 6 is connected to the X-direction The mobile unit 2 is perpendicular to each other, and the Y-direction mobile unit 2 is set on the workbench 10. The Y-direction mobile unit can drive the positioning pallet 5 to move, and the positioning pallet 5 supports the workpiece. The X-direction mobile unit is provided with at least one transfer frame 4 to drive the positioning pallet. The workbench and the machinery that needs to be loaded and unloaded, such as a press machine, run between them, and the positioning tray is equipped with a clamping mechanism for clamping the workpiece.

[0053] It can be understood that, through the arrangement of the X-direction movin...

Embodiment 2

[0080] This embodiment provides a press-fitting machine, including a press-fitting machine 1, referring to figure 1 As shown, at least one side of the press machine 1 is provided with a device for loading and unloading described in Embodiment 1.

[0081] In this embodiment, a device for loading and unloading is provided on both sides of the press-fitting machine 1, and the press-fitting machine adopts existing press-fitting equipment;

[0082] The press-fitting machine has a support table, and the support table is provided with a rotatable turntable 8. When the transfer frame drives the positioning tray to move to the turntable 8 of the press-fitting machine, the positioning tray contacts the turntable 8 so that the turntable drives the positioning tray to rotate, so as to facilitate the secondary pressing. Pack.

[0083] Specifically, the turntable is a circular turntable, and the turntable is connected to a rotating power source such as a rotating motor, and the rotating mo...

Embodiment 3

[0087] This embodiment provides an application of equipment for loading and unloading, which is applied to the press-fitting of gear bearings and gear shafts of rail vehicles.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com