Automatic bending equipment for flexible circuit board

A technology for circuit flexible boards and equipment, which is applied in the field of automatic bending equipment for circuit flexible boards, can solve the problems of high product cost, slow bending speed, and poor quality consistency of PCB boards, so as to increase production rate and fast bending speed , good bending effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make it easier for those skilled in the art to understand the present invention, the specific implementation manners of the present invention will be described below with reference to the accompanying drawings.

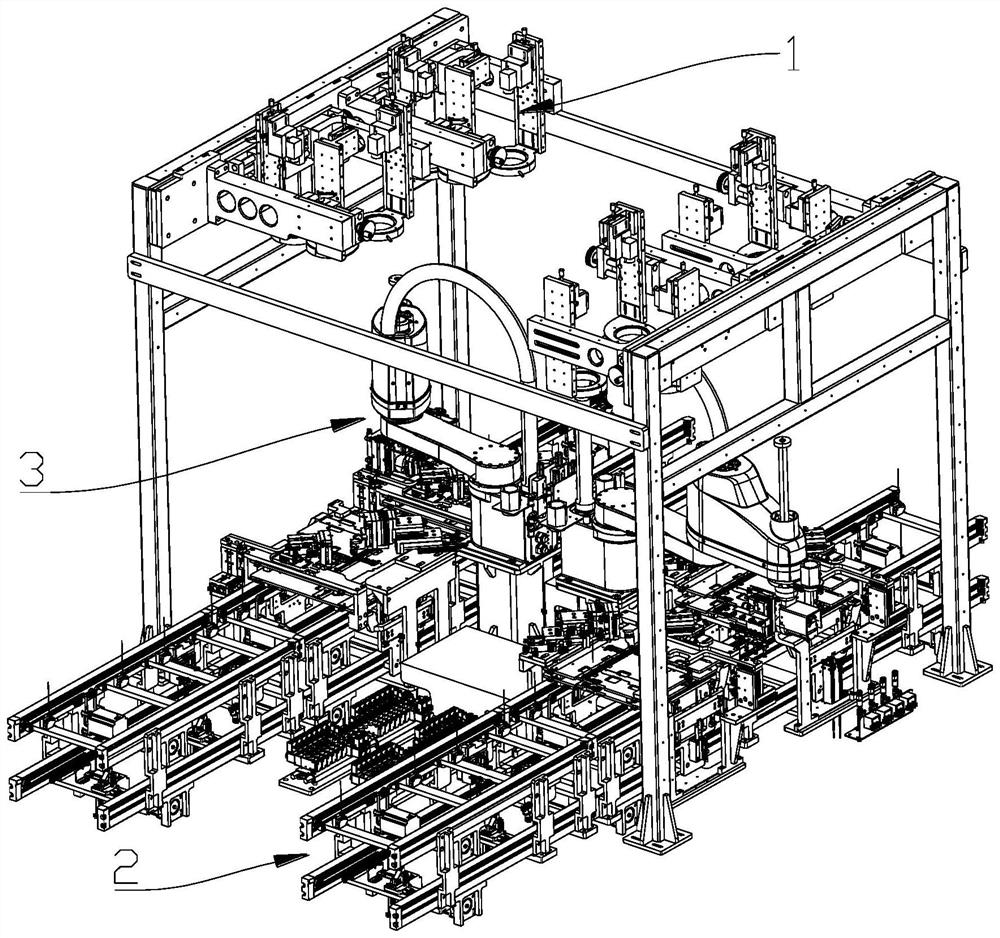

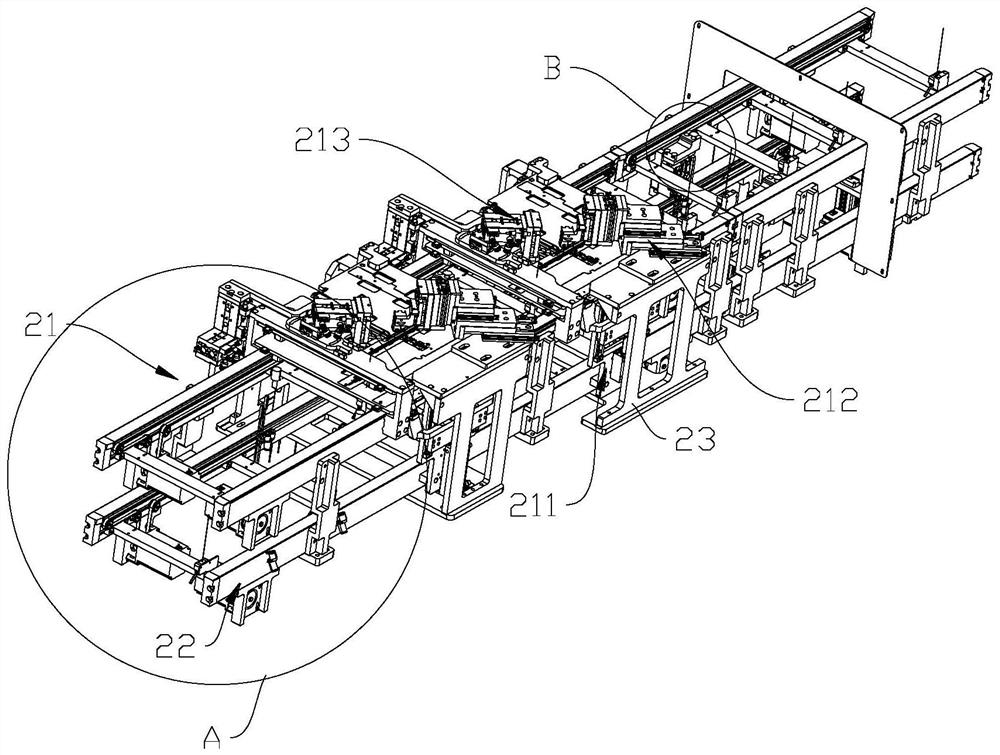

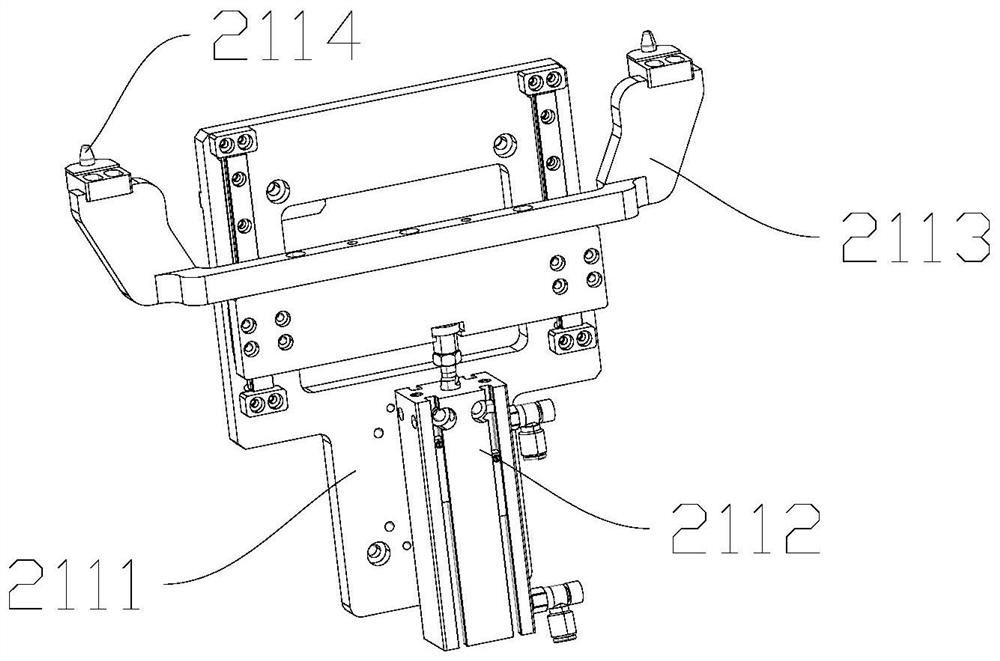

[0027] Such as Figure 1-9 As shown, the present invention provides an automatic bending equipment for circuit flexible boards, including a CCD camera module 1, a mechanical arm module 3 is provided at the lower end of the CCD camera module 1, and a mechanical arm module 3 is provided at the lower end of the mechanical arm module 3. The assembly line module 2, the mechanical arm module 3 includes a four-axis arm 31, and the end of the four-axis arm 31 is provided with a metal tool bending module 32,

[0028] By setting the CCD camera module 1, the real-time detection of the crease and bending position of the circuit flexible board is realized, and unqualified products are prevented from flowing into the downstream process. Through the mechanical arm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com