Transfer tool based on heating and demolding of PCM prepreg laying layer

A transfer worker and prepreg technology, applied in the field of heating and demoulding based on PCM prepreg, can solve the problems of product edge damage, affecting the appearance quality of the equipment, and the product is not easy to separate, so as to reduce the peeling time, The effect of improving the efficiency of reuse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

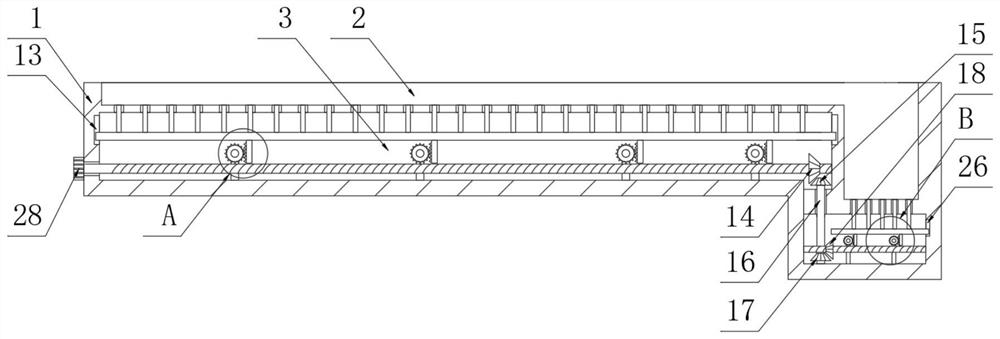

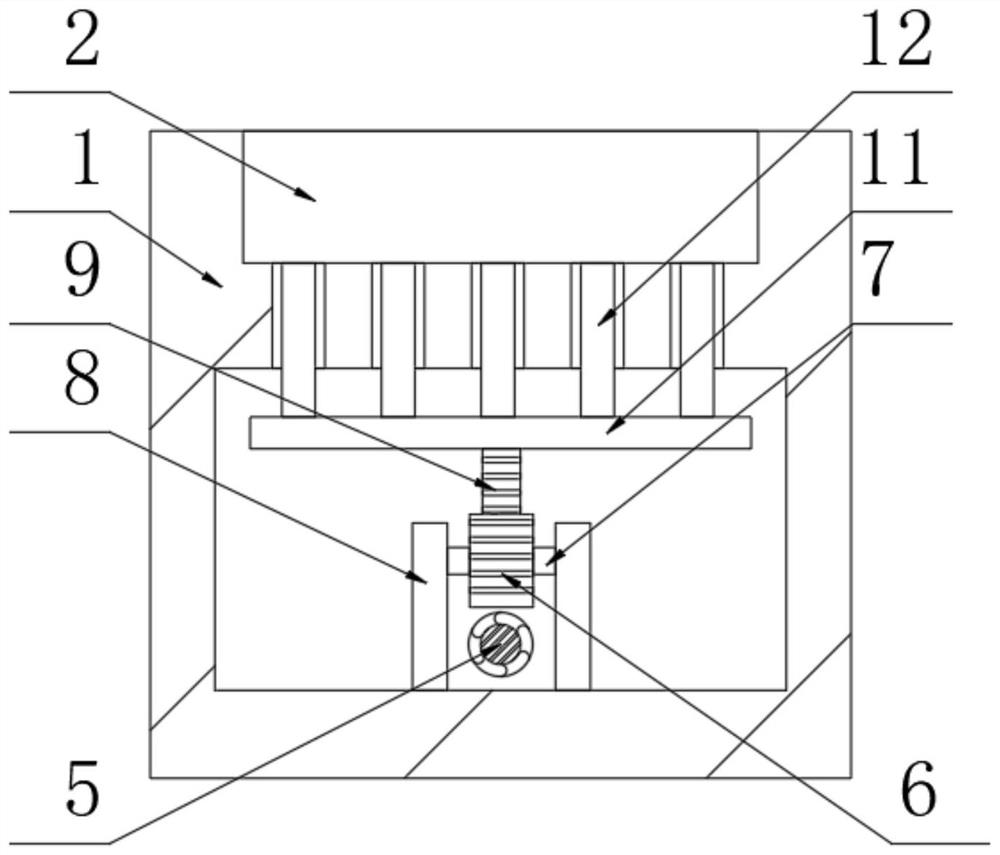

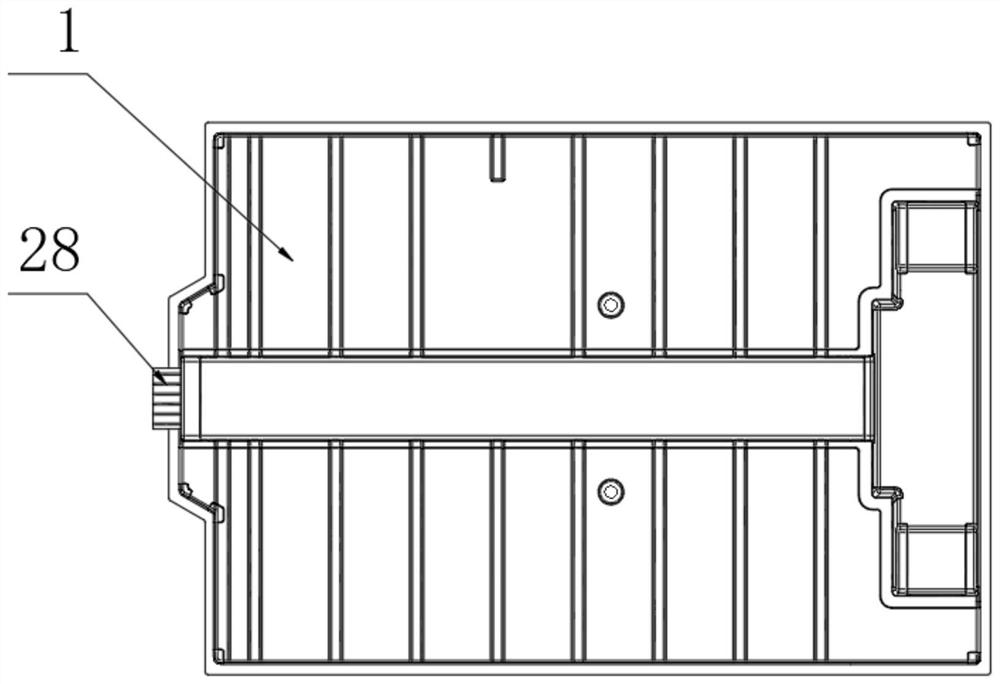

[0028] Such as figure 1 As shown, the embodiment of the present invention provides a transfer tooling based on PCM prepreg layer heating and demoulding, including a board body 1, a product tank 2 is opened on the upper surface of the board body 1, and the inner wall of the product tank 2 A first cavity 3 is opened on the left side of the product tank 2, a second cavity 4 is opened on the right side of the inner wall of the product tank 2, and a first worm 5 is connected to the right side of the inner wall of the first cavity 3 in rotation. The rod wall of a worm 5 is meshed with a plurality of first worm wheels 6, and the inner walls of a plurality of the first worm wheels 6 are provided with a rotating mechanism, the first longitudinal rotating rod 7 of the rotating mechanism, and the first longitudinal rotating rod The rod wall of 7 is fixedly connected with the inner wall of the first worm wheel 6, the first support plate 8 is fixedly connected with the front and rear ends ...

Embodiment 2

[0030] Such as figure 1 and figure 2As shown, the embodiment of the present invention provides a transfer tooling based on PCM prepreg layer heating and demoulding, the lower side of the vertical rotating rod 16 rod wall is fixedly connected with a third sector gear 17, the third The right side surface of the sector gear 17 is meshed with a fourth sector gear 18, the inner wall of the fourth sector gear 18 is fixedly connected with a second worm 19, and the left and right ends of the second worm 19 are connected to the second cavity 4 respectively. The left and right sides of the inner wall are rotationally connected, and the rod wall of the second worm 19 is meshed with two second worm wheels 20, and the inner walls of the two second worm wheels 20 are fixedly connected with a second longitudinal rotating rod 21. The front and rear ends of the second longitudinal rotating rod 21 are fixedly connected with a second support plate 22, and the lower surfaces of the plurality of...

Embodiment 3

[0032] Such as figure 2 and image 3 As shown, the embodiment of the present invention provides a transfer tooling based on PCM prepreg layup heating and demoulding, and the right side surfaces of the two second worm wheels 20 are meshed with the second worm wheels 20. Two gear bars 23, the right side surfaces of the two second gear bars 23 are fixedly connected with the second struts 24, and the upper ends of the two second struts 24 are fixedly connected with the second push plate 25, so The right side of the inner wall of the second cavity 4 is provided with a second chute 26 that matches the second push plate 25. The upper surface of the second push plate 25 is fixedly connected with a plurality of second thimbles 27. The upper end of the second thimble 27 runs through the upper side of the inner wall of the second cavity 4 and extends to the inner wall of the product tank 2, and the right end of the first worm wheel 6 is fixedly connected with a rotor 28, and the surfac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com