Regional ultrasonic impact strengthening method for thin-wall blade

An ultrasonic impact, sub-regional technology, applied in the field of thin-walled blade surface strengthening, can solve the problems of large blade surface roughness and poor processing controllability, and achieve the effect of improving surface roughness and avoiding processing deformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

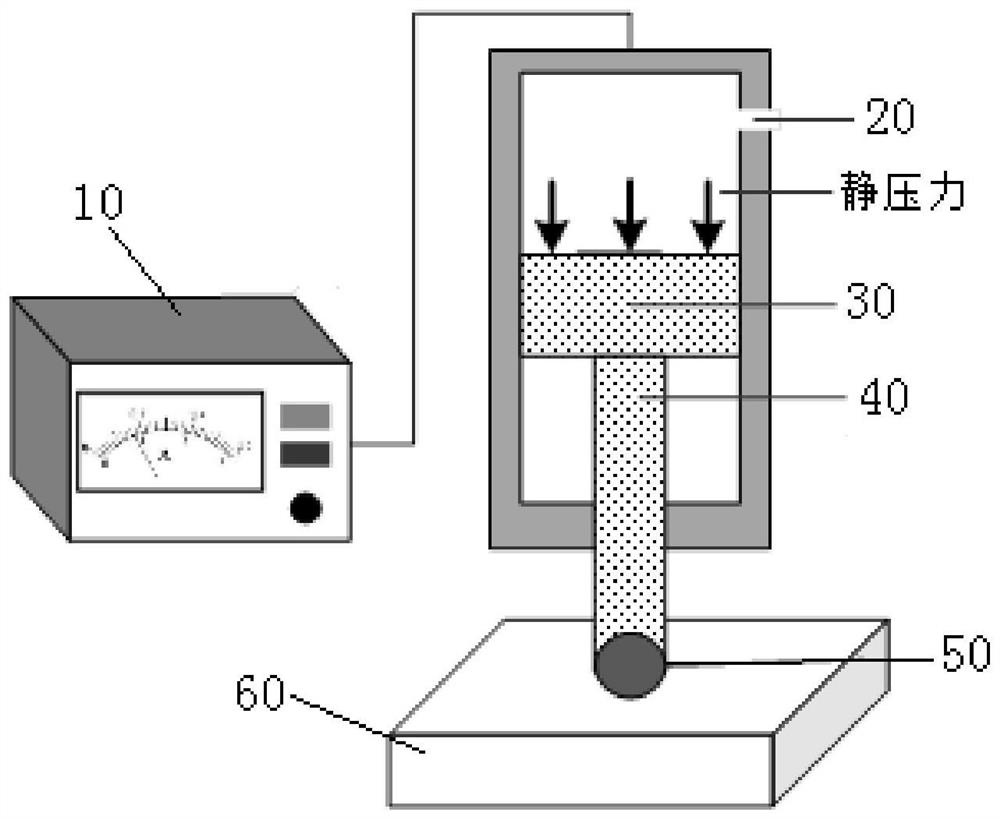

[0041] Compared with other processes, ultrasonic impact strengthening has the advantages of controllable processing path, convenient operation, and can produce considerable surface strengthening layer with less force. However, ultrasonic impact strengthening is usually used in the strengthening of plane and shaft workpieces, because for thin-walled curved parts such as aero-engine blades, the deformation caused by ultrasonic impact strengthening processing is a problem that must be considered.

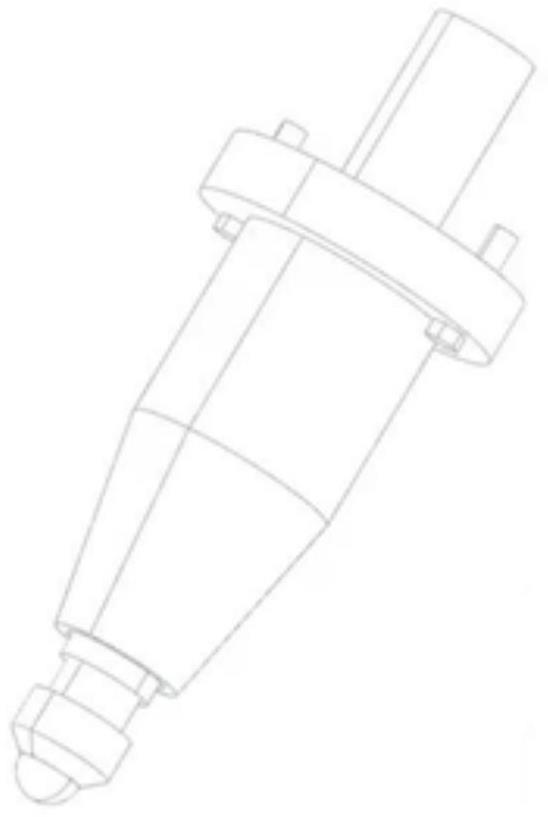

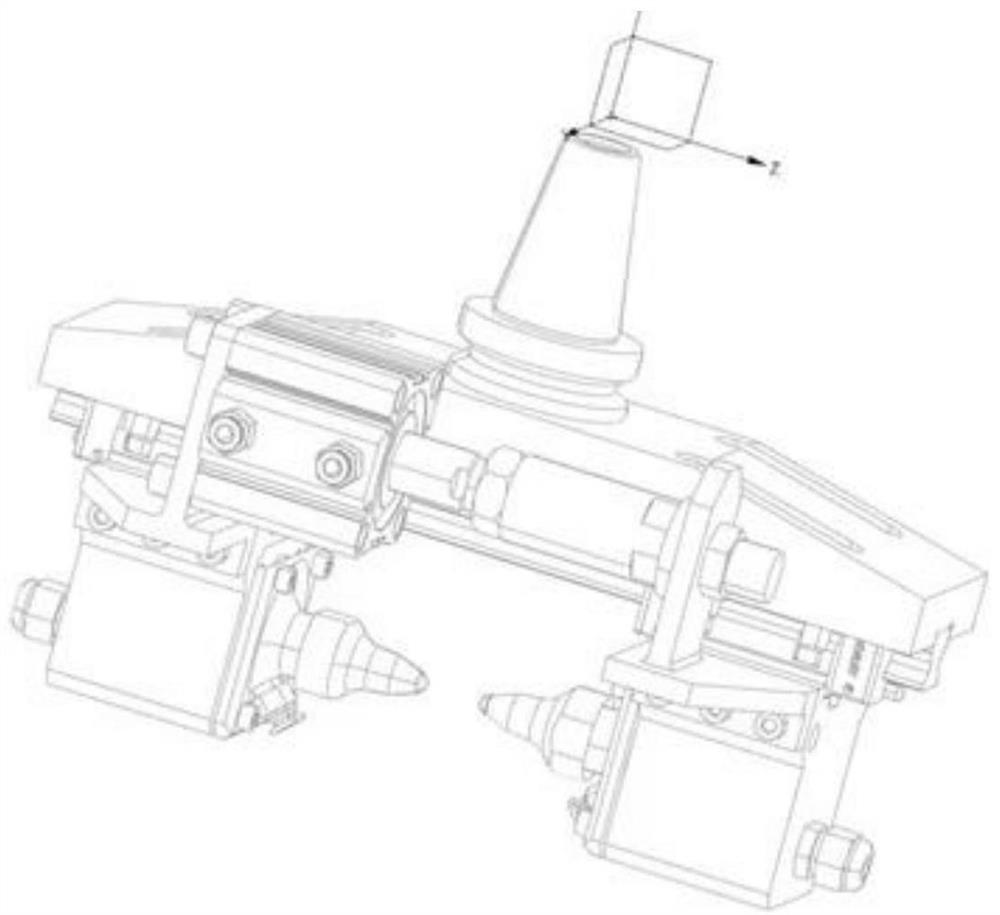

[0042] The sub-area ultrasonic impact strengthening method of the present invention combines the ultrasonic impact tool with the five-axis numerical control machine tool, expands the application range of the ultrasonic impact strengthening process to thin-walled parts such as aero-engine blades, and provides surface strengthening for complex thin-walle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com