Pressure-bearing sealing device for pumping well

A technology for pressure-bearing sealing and pumping wells, which is applied to wellbore/well valve devices, sealing/isolation, wellbore/well components, etc., which can solve problems such as inability to observe pressure, poor sealing performance and safety and reliability, and achieve Avoid unexpected accidents, facilitate follow-up work, and improve safety and sealing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

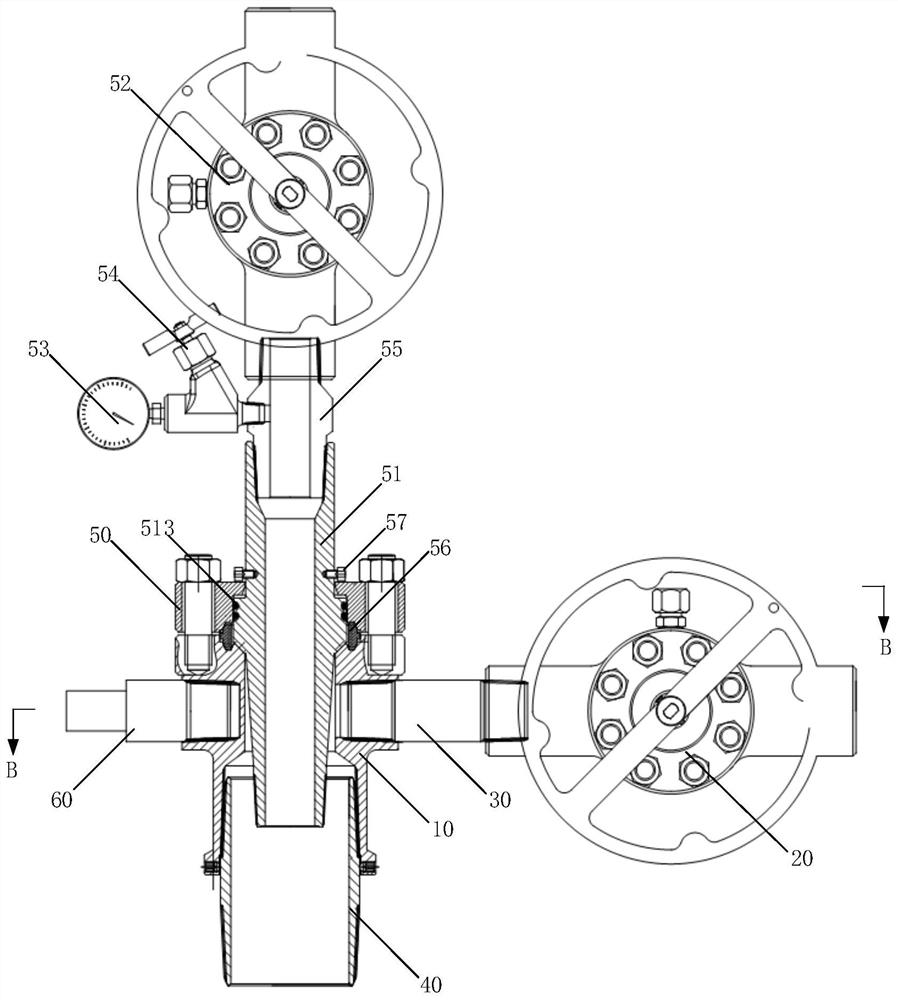

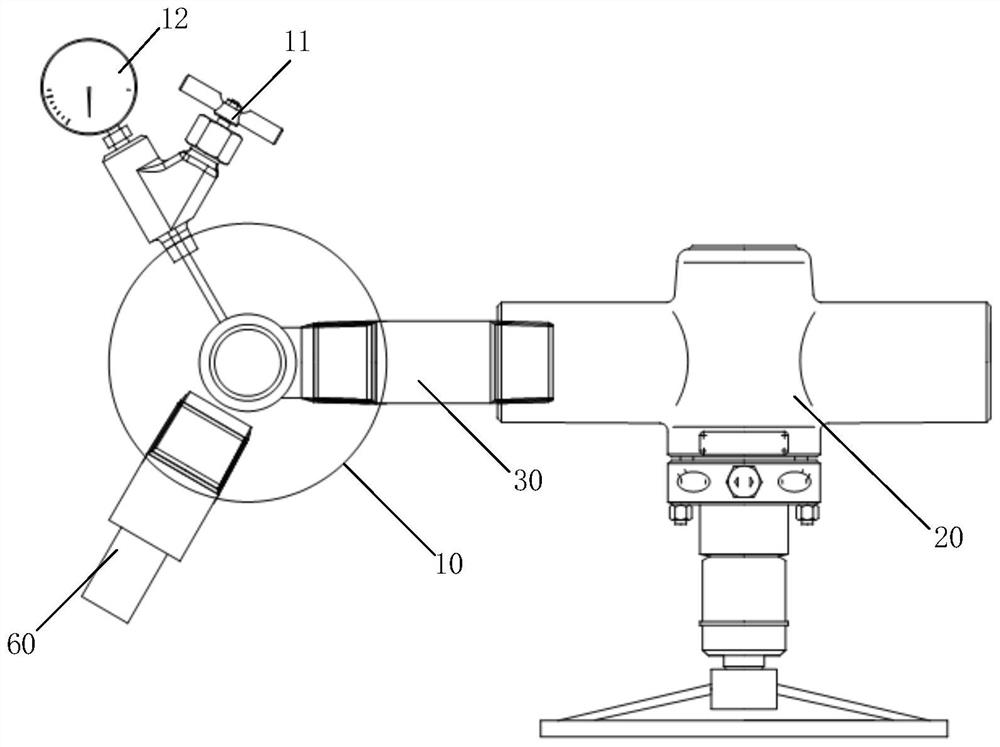

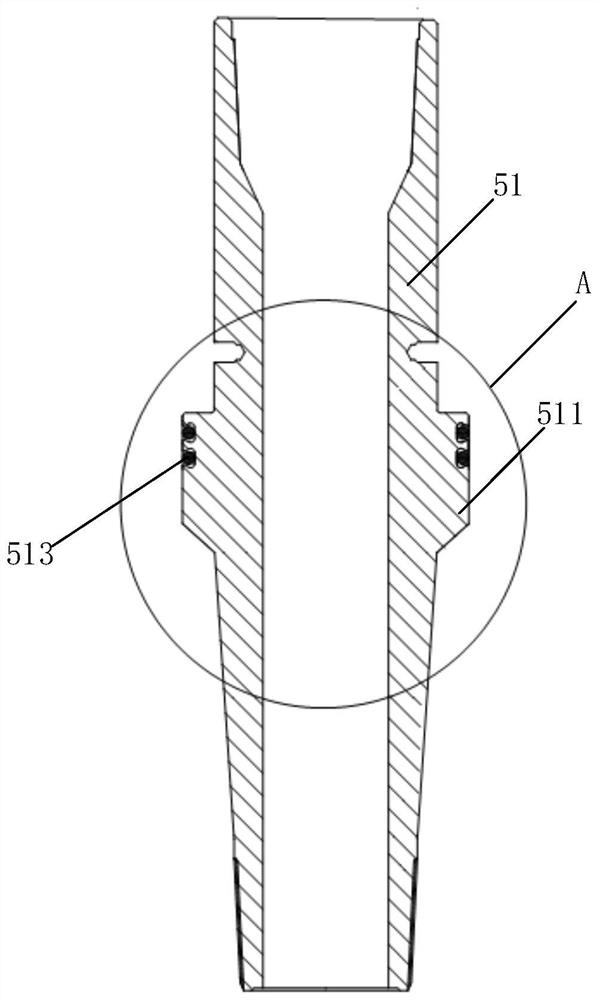

[0036] See figure 1 , a pressure-bearing sealing device for pumping wells, comprising: including: a tee joint 10, a second vent valve 20, a second double male short-connector 30, a casing short-connector 40 and a sealing assembly. The first interface of the tee joint 10 is connected with one end of the casing short 40 through a thread seal; the other end of the casing short 40 is connected with the casing at the wellhead of the production well through a thread seal. The second interface of the three-way joint 10 is tightly connected to one end of the second double male short connector 30 through threads; the other end of the second double male short connector 30 is tightly connected to the second vent valve 20 through threads. The bushing short 40 communicates with the second interface of the tee joint 10 .

[0037] In this embodiment, the second vent valve 20 is used to perform the vent operation when venting is required in the oil production well. Open the second vent valve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com